Yong-In City

Sort by

EUGENE TECHNOLOGY

Semi conductor equipment manufacturer, Blue jay system, Poly silicon thin film and more

CSK

Semi conductor, LCD facility manufacturer, Scrubber, PDS

BEE RYONG ELECTRONICS

Terminal electronic parts manufacturer, Terminal block, Connector, PCB, Assembly

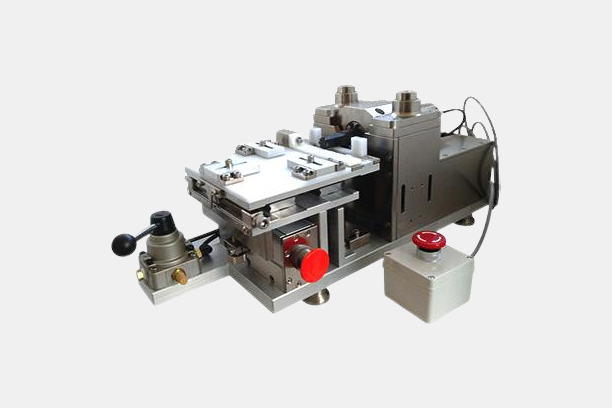

KORMAX SYSTEM

Ultrasonic metal welding equipment manufacturer

TES

Semi conductor manufacturer, LCD, FPD equipment, Software

ACE ELECTRONIC

Vacuum cleaner manufacturer, Socks wireless cleaner, Vacuum cleaner, For Home, Automotive, Hand blender and more

HANKOOK C&S

Material handling system manufacturer, Round conveyor, Multi stage flexible conveyor, Pre curve conveyor and more

NAMBUK

Metal machine tools manufacturer, Upright drilling Machine, Radial drilling machine, Milling machine and more

CHARMGRAPHENE

Manufacturer of Graphene, Graphene CVD, Semi conductor display and Vacuum equipment

CHARM ENGINEERING

FPD, Semi conductor equipment manufacturer, Laser repair, Bevel etcher