Premium Members

Sort by

PEI GENESIS, INC.

Verified & Trusted Manufacturer

Cable Assembles Manufacturer, Connectors, Sensors, Controls, Tools, Accessories and more

SAMHWAN MACHINE

Verified & Trusted Manufacturer

Specialist Suppliers of Rebar Cutter, Rebar Bender

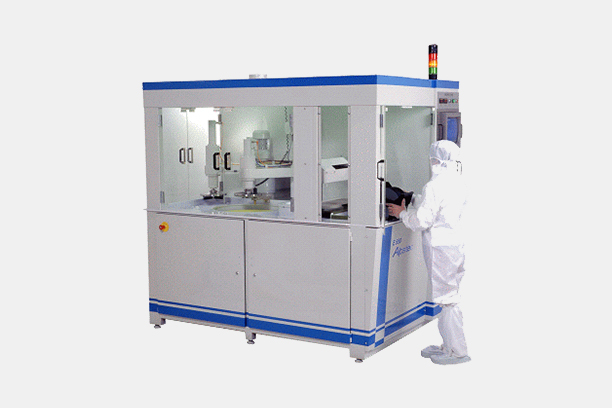

ALPSITEC

Verified & Trusted Manufacturer

CMP Machines Manufacturer

FIVES CRYO

Verified & Trusted Manufacturer

Manufacturer of Material Removal, Grinding, Cutting Tools, Laser System and more

STIRWELD

Verified & Trusted Manufacturer

FSW Supplier, FSM Heads, FSM Tools, FSW Accesories

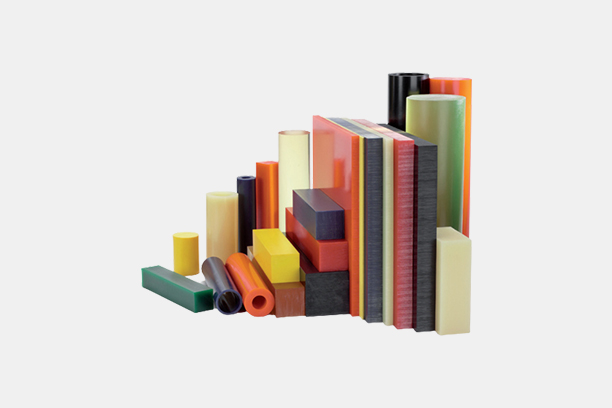

FIMOR POLYURETHANE

Verified & Trusted Manufacturer

Specialist of Cast Polyurethane Parts

FIMOR SAS

Verified & Trusted Manufacturer

Manufacturer of Serilor® Products, Squeegees, Sharpeners and Accessories for All Screen Printing Applications

SABATIER S.A.S.

Verified & Trusted Manufacturer

Manufacturer of Complete Production Lines for Industrial Packaging

NEYRET GROUP

Verified & Trusted Manufacturer

Manufacturer of Assembly Automation and Equipment

CHROMATOTEC

Verified & Trusted Manufacturer

Manufacturer of Auto GC866 Analyzers, Mass Spectrometers, Peripherals and more