Overview

- Summary

- SABATIER S.A.S. is a global manufacturer of complete production lines for industrial packaging, specializing in systems for cylindrical, conical, and irregularly shaped 3-piece metal containers (cans, pails, drums). The company joined the Soudronic Group in 1995, strengthening its position in the global market.SABATIER S.A.S. is a global manufacturer of complete production lines for industrial packaging, specializing in systems for cylindrical, conical, and irregularly shaped 3-piece metal containers (cans, pails, drums). The company joined the Soudronic Group in 1995, strengthening its position in the global market.

- Key Products/Technologies

- Sabatier S.A.S. offers products such as Curlipack, Air Cleaner for 18L Square Can, Bailypack for Plastic Pails, Bailypack 5 TO 10 for Metallic Pails, Handlepack, Carousel Leak Tester, Bodystacker Single Lane, Bodystacker Double Lane, and Bodypack 200.Sabatier S.A.S. offers products such as Curlipack, Air Cleaner for 18L Square Can, Bailypack for Plastic Pails, Bailypack 5 TO 10 for Metallic Pails, Handlepack, Carousel Leak Tester, Bodystacker Single Lane, Bodystacker Double Lane, and Bodypack 200.

- The company provides a wide range of production systems for cylindrical, conical, or irregularly shaped 3-piece metal containers (cans, pails, and drums), including custom-made turnkey systems and stand-alone machines.The company provides a wide range of production systems for cylindrical, conical, or irregularly shaped 3-piece metal containers (cans, pails, and drums), including custom-made turnkey systems and stand-alone machines.

- Key product lines include Bodypack, Squarepack, Bodyshaper, Handlepack, Bailypack, Leak Tester, Curlipack Curler-Liner, and Curler - Blueliner.Key product lines include Bodypack, Squarepack, Bodyshaper, Handlepack, Bailypack, Leak Tester, Curlipack Curler-Liner, and Curler - Blueliner.

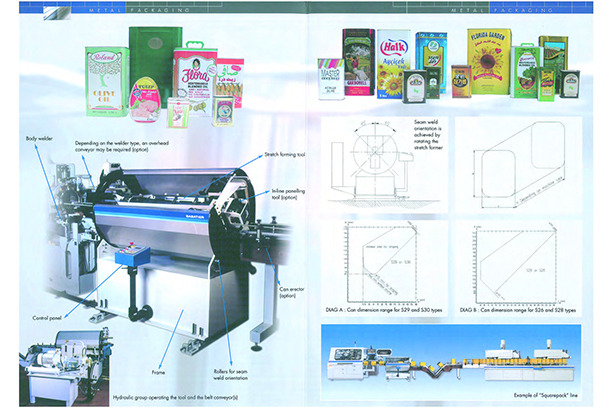

- The Bodypack machine is a compact, high-efficiency canbody former for round can production, featuring a modular construction that integrates multiple functions like necking, spin-flanging, die-flanging, inner or outer curling, beading, bottom and top end seaming, expansion, or shaping into a single machine.The Bodypack machine is a compact, high-efficiency canbody former for round can production, featuring a modular construction that integrates multiple functions like necking, spin-flanging, die-flanging, inner or outer curling, beading, bottom and top end seaming, expansion, or shaping into a single machine.

- Squarepack bodyformers are compact, reliable, and highly efficient systems for irregularly shaped cans, performing all necessary expanding, paneling, flanging, and seaming operations on square, rectangular, prismatic, or oblong canbodies with capacities from 0.2 to 20 liters.Squarepack bodyformers are compact, reliable, and highly efficient systems for irregularly shaped cans, performing all necessary expanding, paneling, flanging, and seaming operations on square, rectangular, prismatic, or oblong canbodies with capacities from 0.2 to 20 liters.

- The Blue Liner robot technology provides fully robotized lining for curling and lining irregular ends, offering flexibility and user-friendliness, including compound placement adjustment to compensate for process variations and the ability to produce multiple types of bottom ends on the same machine.The Blue Liner robot technology provides fully robotized lining for curling and lining irregular ends, offering flexibility and user-friendliness, including compound placement adjustment to compensate for process variations and the ability to produce multiple types of bottom ends on the same machine.

- As part of the Soudronic Group, Sabatier leverages a complete range of machines and components for the can-making industry, focusing on 3-piece and 2-piece can production lines and end-making systems, including welding machines operating at speeds up to 1,200 cans per minute.As part of the Soudronic Group, Sabatier leverages a complete range of machines and components for the can-making industry, focusing on 3-piece and 2-piece can production lines and end-making systems, including welding machines operating at speeds up to 1,200 cans per minute.

- The modular and versatile construction of Sabatier's equipment allows for various configurations tailored to customer needs, combining multiple functions such as necking, flanging, beading, curling, seaming, expansion, or shaping into a single machine.The modular and versatile construction of Sabatier's equipment allows for various configurations tailored to customer needs, combining multiple functions such as necking, flanging, beading, curling, seaming, expansion, or shaping into a single machine.

- Core Advantages

- A leading global manufacturer of complete production lines for industrial packaging, with specialized expertise in 3-piece metal container production systems.A leading global manufacturer of complete production lines for industrial packaging, with specialized expertise in 3-piece metal container production systems.

- Integration within the Soudronic Group, enabling access to a comprehensive product range and advanced technologies for 3-piece and 2-piece can production lines and end-making systems.Integration within the Soudronic Group, enabling access to a comprehensive product range and advanced technologies for 3-piece and 2-piece can production lines and end-making systems.

- High-speed production capabilities of up to 1,200 cans per minute (cpm) and advanced technology for processing downgauged tinplate as thin as 0.1mm, contributing to resource savings and reduced carbon emissions.High-speed production capabilities of up to 1,200 cans per minute (cpm) and advanced technology for processing downgauged tinplate as thin as 0.1mm, contributing to resource savings and reduced carbon emissions.

- Modular and versatile equipment construction offering diverse configurations to meet specific customer requirements, integrating multiple functions into a single machine for high productivity and product quality.Modular and versatile equipment construction offering diverse configurations to meet specific customer requirements, integrating multiple functions into a single machine for high productivity and product quality.

- Compact machine designs that save factory floor space and prevent product damage, achieved through step-by-step body transfer and vertical working stations.Compact machine designs that save factory floor space and prevent product damage, achieved through step-by-step body transfer and vertical working stations.

- Fully electrical, servo-driven motion systems resulting in 20-50% electrical consumption savings compared to hydraulic systems and eliminating the risk of oil contamination.Fully electrical, servo-driven motion systems resulting in 20-50% electrical consumption savings compared to hydraulic systems and eliminating the risk of oil contamination.

- User-friendly operation and diagnostic features via a centralized touchscreen control panel, with integration of Industry 4.0 and Soudronic Digital Solutions for innovative problem-solving.User-friendly operation and diagnostic features via a centralized touchscreen control panel, with integration of Industry 4.0 and Soudronic Digital Solutions for innovative problem-solving.

- Implementation of the Soudronic Food Safety Standard, ensuring enhanced food safety through the use of NSF-H1 approved lubricants and plastic components certified to EU/FDA standards.Implementation of the Soudronic Food Safety Standard, ensuring enhanced food safety through the use of NSF-H1 approved lubricants and plastic components certified to EU/FDA standards.

- An extensive global sales and service network spanning over 120 countries, providing comprehensive after-sales support and prompt spare parts supply.An extensive global sales and service network spanning over 120 countries, providing comprehensive after-sales support and prompt spare parts supply.

- Target Industrie

- Food and beverage can productionFood and beverage can production

- Aerosol can productionAerosol can production

- Industrial packaging (paints, lubricants, chemicals, etc.)Industrial packaging (paints, lubricants, chemicals, etc.)

- Drum and pail productionDrum and pail production

- Medical packaging (future expansion plans)Medical packaging (future expansion plans)

- Major Markets

- China, Singapore, Malaysia, Indonesia, Thailand, Across AsiaChina, Singapore, Malaysia, Indonesia, Thailand, Across Asia

- Switzerland, France, Italy, Across EuropeSwitzerland, France, Italy, Across Europe

- USA, Mexico, Across North AmericaUSA, Mexico, Across North America

- Across Latin AmericaAcross Latin America

- Certifications/Patents

- Holds ISO 9001:2015 Quality Management System certification, undergoing annual audits and triennial recertification processes.Holds ISO 9001:2015 Quality Management System certification, undergoing annual audits and triennial recertification processes.

- Introduced the Soudronic Food Safety Standard in 2023, providing declarations of conformity, utilizing NSF-H1 approved lubricants, and incorporating plastic components certified to EU/FDA standards.Introduced the Soudronic Food Safety Standard in 2023, providing declarations of conformity, utilizing NSF-H1 approved lubricants, and incorporating plastic components certified to EU/FDA standards.

- Soudronic AG possesses numerous patents, including those for apparatus and method for manufacturing lids with tear-off foil (US Patent 9764374), magnetic lifting device for can bodies (US Patent 9845197), method and welding apparatus for determining welding current strength for container bodies (US Patent 10022814), and method and device for producing tear-off lids (US Patent 11142369).Soudronic AG possesses numerous patents, including those for apparatus and method for manufacturing lids with tear-off foil (US Patent 9764374), magnetic lifting device for can bodies (US Patent 9845197), method and welding apparatus for determining welding current strength for container bodies (US Patent 10022814), and method and device for producing tear-off lids (US Patent 11142369).

- The Soudronic Group has received various awards and certifications reflecting its strong commitment to quality, innovation, and customer satisfaction.The Soudronic Group has received various awards and certifications reflecting its strong commitment to quality, innovation, and customer satisfaction.

- Awarded first place in the Swiss Arbeitgeber Award 2022 in the category of 250 to 999 employees.Awarded first place in the Swiss Arbeitgeber Award 2022 in the category of 250 to 999 employees.

- Recognized with a Bronze Award for the PowerCUT SuperFLEX slitter in 2023, a Bronze Award for the SOUCAN 2075 canbody welder in 2014, and a Silver Award for ring-pull solutions in 2011, among other product-related accolades.Recognized with a Bronze Award for the PowerCUT SuperFLEX slitter in 2023, a Bronze Award for the SOUCAN 2075 canbody welder in 2014, and a Silver Award for ring-pull solutions in 2011, among other product-related accolades.

Introduction

Key Products

Location

Industriestrasse 35, 8962 Bergdietikon, Switzerland

클릭하여 위치 살펴보기