Overview

- Summary

- FIMOR SAS, a leading manufacturer of polyurethane squeegees and related accessories for screen printing since 1977FIMOR SAS, a leading manufacturer of polyurethane squeegees and related accessories for screen printing since 1977

- Key Products/Technologies

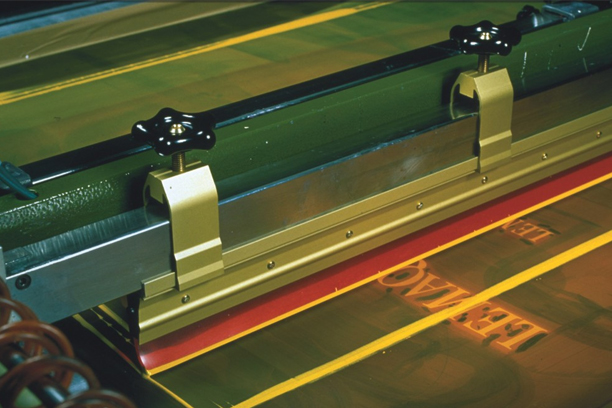

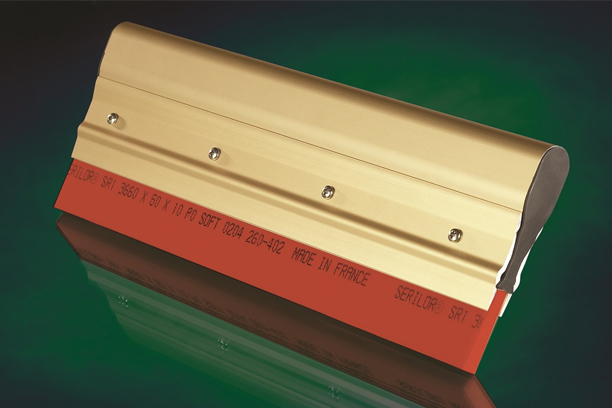

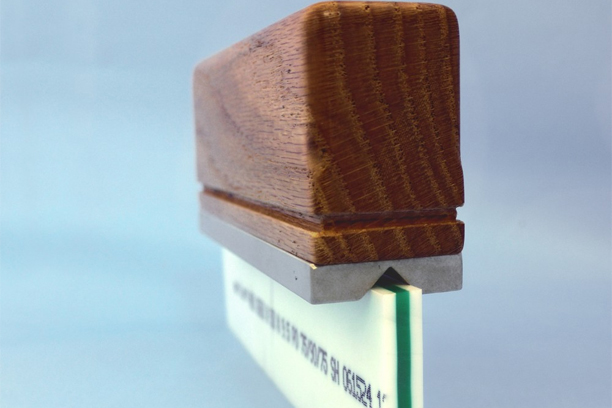

- Serilor®SR – Universal Use Squeegee is an all-purpose polyurethane blade featuring good combined resistance to chemicals and abrasion. It is suitable for various screen printing applications, serving as an ideal choice for non-critical abrasive uses or with common screen inks, meeting the industry standard S1 grade. This squeegee blade is manufactured through a centrifugation process to prevent bubbles and craters within the material, ensuring optimal homogeneity even at its core. An exclusive computer-controlled casting process guarantees batch-to-batch consistency, with hardness ranging from 60 to 90 ShA and various color options.Serilor®SR – Universal Use Squeegee is an all-purpose polyurethane blade featuring good combined resistance to chemicals and abrasion. It is suitable for various screen printing applications, serving as an ideal choice for non-critical abrasive uses or with common screen inks, meeting the industry standard S1 grade. This squeegee blade is manufactured through a centrifugation process to prevent bubbles and craters within the material, ensuring optimal homogeneity even at its core. An exclusive computer-controlled casting process guarantees batch-to-batch consistency, with hardness ranging from 60 to 90 ShA and various color options.

- Serilor®LC – Best Value Grade Squeegee represents a new polyurethane formulation developed to achieve performance at an attractive price point. It is suitable for non-critical applications ranging from textile to graphic printing, available in a limited range of dimensions and hardness combinations. This blade is also produced via a centrifugation process, ensuring material homogeneity and bubble-free surfaces, maintaining consistent quality through computer-controlled casting. Notably, Serilor®LC3 is a triple-durometer squeegee with a 90shA hard center layer, ideal for fine lines and halftone printing.Serilor®LC – Best Value Grade Squeegee represents a new polyurethane formulation developed to achieve performance at an attractive price point. It is suitable for non-critical applications ranging from textile to graphic printing, available in a limited range of dimensions and hardness combinations. This blade is also produced via a centrifugation process, ensuring material homogeneity and bubble-free surfaces, maintaining consistent quality through computer-controlled casting. Notably, Serilor®LC3 is a triple-durometer squeegee with a 90shA hard center layer, ideal for fine lines and halftone printing.

- Serilor®HR – High Resistance Squeegee is a special polyurethane blade offering exceptional combined resistance to chemicals and abrasion. It was developed to withstand the toughest screen printing applications and ensure a long shelf life in most environments. The centrifugation process ensures optimal homogeneity throughout the material, including its core, while an exclusive computer-controlled casting process guarantees batch-to-batch consistency. This product is particularly suited for industrial and UV inks requiring maximum abrasion and chemical resistance.Serilor®HR – High Resistance Squeegee is a special polyurethane blade offering exceptional combined resistance to chemicals and abrasion. It was developed to withstand the toughest screen printing applications and ensure a long shelf life in most environments. The centrifugation process ensures optimal homogeneity throughout the material, including its core, while an exclusive computer-controlled casting process guarantees batch-to-batch consistency. This product is particularly suited for industrial and UV inks requiring maximum abrasion and chemical resistance.

- Diamond KUT Sharpener (models: DK-160, DK-176, DK-260, DK-276) is a high-quality manual sharpener for long-length squeegees. It can sharpen squeegees up to 153 cm (60 inches) or 193 cm (76 inches) in length, eliminating operator errors by securely maintaining the squeegee parallel to the diamond wheel during sharpening. This sharpener accommodates a wide range of squeegee materials, including single and multiple durometer, and includes two indestructible diamond sharpening wheels with a 5-year warranty.Diamond KUT Sharpener (models: DK-160, DK-176, DK-260, DK-276) is a high-quality manual sharpener for long-length squeegees. It can sharpen squeegees up to 153 cm (60 inches) or 193 cm (76 inches) in length, eliminating operator errors by securely maintaining the squeegee parallel to the diamond wheel during sharpening. This sharpener accommodates a wide range of squeegee materials, including single and multiple durometer, and includes two indestructible diamond sharpening wheels with a 5-year warranty.

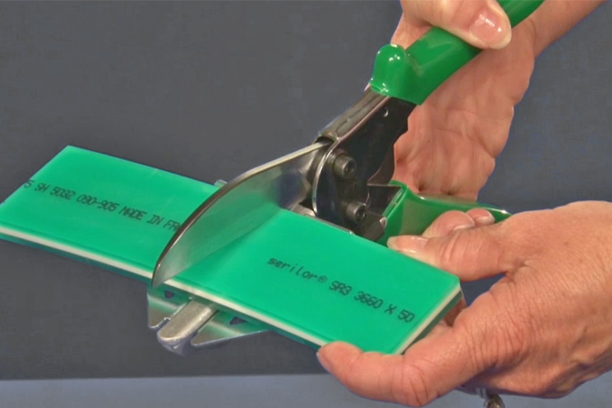

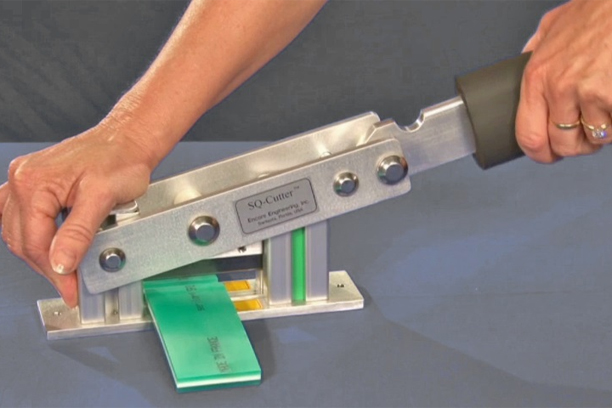

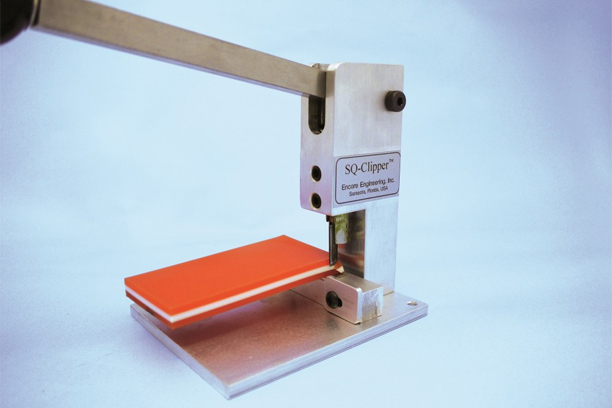

- Diamond SHORT-CUT Sharpener (models: DSC-020, DSC-220) is a small-format, manual precision sharpener for screen printing squeegees 51 cm (20 inches) or less. Its portable tabletop design allows for placement anywhere, equipped with a single industrial-strength diamond sharpening wheel. It provides uniform grinding pressure and material removal adjustment, accommodating various squeegee holders. The sharpener includes a diamond wheel with a 5-year warranty, and the 220V model comes with a spare parts kit.Diamond SHORT-CUT Sharpener (models: DSC-020, DSC-220) is a small-format, manual precision sharpener for screen printing squeegees 51 cm (20 inches) or less. Its portable tabletop design allows for placement anywhere, equipped with a single industrial-strength diamond sharpening wheel. It provides uniform grinding pressure and material removal adjustment, accommodating various squeegee holders. The sharpener includes a diamond wheel with a 5-year warranty, and the 220V model comes with a spare parts kit.

- Core Advantages

- A global leader in the screen printing squeegee market, having developed the most recognized and best-selling 'serilor®' brand over five decades. The company maintains a strong global market presence, supplying products through a network of over 300 active distributors in more than 80 countries. This extensive distribution network covers all segments of screen printing, including industrial, electronics, glass, textile, labels, and commercial graphics.A global leader in the screen printing squeegee market, having developed the most recognized and best-selling 'serilor®' brand over five decades. The company maintains a strong global market presence, supplying products through a network of over 300 active distributors in more than 80 countries. This extensive distribution network covers all segments of screen printing, including industrial, electronics, glass, textile, labels, and commercial graphics.

- Innovative technological capabilities and standard-setting achievements, exemplified by the introduction of the first color-coded screen printing squeegees in 1982, establishing new world standards. The unique centrifugation process in polyurethane squeegee manufacturing ensures bubble-free, uniform thickness and optimal material homogeneity. Furthermore, a proprietary computer-controlled casting process guarantees consistent quality across batches, with complete traceability from raw materials to finished products.Innovative technological capabilities and standard-setting achievements, exemplified by the introduction of the first color-coded screen printing squeegees in 1982, establishing new world standards. The unique centrifugation process in polyurethane squeegee manufacturing ensures bubble-free, uniform thickness and optimal material homogeneity. Furthermore, a proprietary computer-controlled casting process guarantees consistent quality across batches, with complete traceability from raw materials to finished products.

- A comprehensive product portfolio and custom solution capabilities meeting diverse industrial requirements. Beyond screen printing, the company develops polyurethane products for industrial cleaning, railway, acoustic insulation, industrial protection, agriculture, and sports. Its casting processes allow for a wide range of hardness combinations, from very flexible to very rigid, and the integration of polyurethane with other flexible or rigid materials, including metals.A comprehensive product portfolio and custom solution capabilities meeting diverse industrial requirements. Beyond screen printing, the company develops polyurethane products for industrial cleaning, railway, acoustic insulation, industrial protection, agriculture, and sports. Its casting processes allow for a wide range of hardness combinations, from very flexible to very rigid, and the integration of polyurethane with other flexible or rigid materials, including metals.

- International standard certifications for quality and environmental management systems. The headquarters and production facilities in Le Mans, France, hold ISO 9001 and ISO 14001 certifications, ensuring consistent manufacturing processes and reliable product performance. Products also comply with REACH, RoHS, and even PaHS standards for low hardnesses, demonstrating a commitment to environmental responsibility and safety. Local offices in Connecticut (USA) and Guangdong (China) provide direct service and support to customers in key markets.International standard certifications for quality and environmental management systems. The headquarters and production facilities in Le Mans, France, hold ISO 9001 and ISO 14001 certifications, ensuring consistent manufacturing processes and reliable product performance. Products also comply with REACH, RoHS, and even PaHS standards for low hardnesses, demonstrating a commitment to environmental responsibility and safety. Local offices in Connecticut (USA) and Guangdong (China) provide direct service and support to customers in key markets.

- Target Industrie

- Screen Printing (Industrial, Electronics, Glass, Textile, Labels, Commercial Graphics)Screen Printing (Industrial, Electronics, Glass, Textile, Labels, Commercial Graphics)

- Industrial Cleaning (Scrubber Dryers)Industrial Cleaning (Scrubber Dryers)

- Railway IndustryRailway Industry

- Acoustic InsulationAcoustic Insulation

- Industrial ProtectionIndustrial Protection

- AgricultureAgriculture

- Sporting GoodsSporting Goods

- General Industry (Material Handling, Chemical Industry, Equestrian Applications)General Industry (Material Handling, Chemical Industry, Equestrian Applications)

- Major Markets

- Vietnam, India, Sri Lanka, Pakistan, Philippines, China, TurkeyVietnam, India, Sri Lanka, Pakistan, Philippines, China, Turkey

- France, GermanyFrance, Germany

- Mexico, United StatesMexico, United States

- Colombia, Ecuador, BoliviaColombia, Ecuador, Bolivia

- Certifications/Patents

- ISO 9001 Quality Management System CertificationISO 9001 Quality Management System Certification

- ISO 14001 Environmental Management System CertificationISO 14001 Environmental Management System Certification

- REACH Standard ComplianceREACH Standard Compliance

- RoHS Standard ComplianceRoHS Standard Compliance

- PaHS Standard Compliance (for low hardness products)PaHS Standard Compliance (for low hardness products)

Introduction

Key Products

Location

210 Rue du Polygone, 72058 Le Mans, France

클릭하여 위치 살펴보기