This product is manufactured by

ALPSITEC

Manufacturer information

ALPSITEC

Verified & Trusted Manufacturer

CMP Machines Manufacturer

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

ALPSITEC

Product Type

Machine

Brand

-

SKU

138998

Product Name

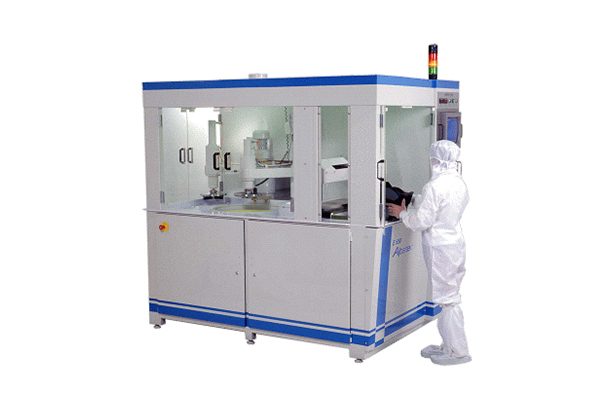

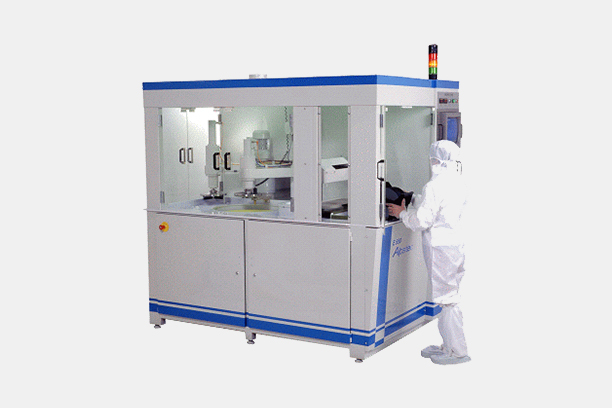

CMP Machines E400 E

Model Name

E400 E

Size

-

Weight

-

Product Details