Premium Members

Sort by

SONY ELECTRONICS OF KOREA CORPORATION

Verified & Trusted Manufacturer

High precision parts manufacturer, Laser Diode, Pick Projector, Integrated Unit

ATLANTIC FLUID TECH

Verified & Trusted Manufacturer

Hydraulic Valve Manufacturer, Relief Valves, Pressure Reducing Valves, Sequence Valves and more

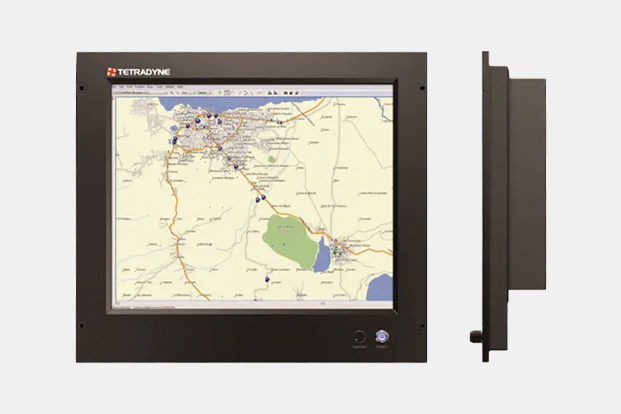

TETRADYNE

Verified & Trusted Manufacturer

Industrial and Marine monitor manufacturer, TFT LCD Monitor

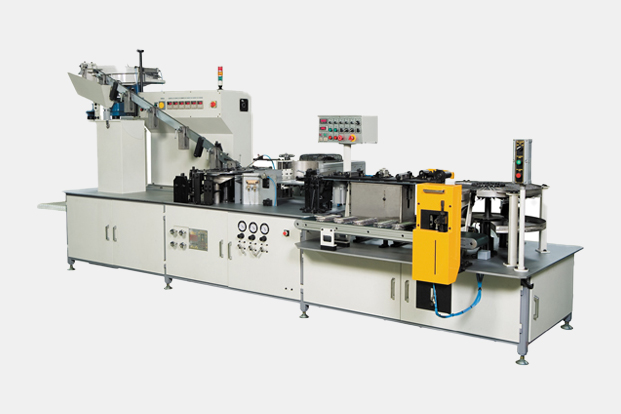

ZEUS TECHNO

Verified & Trusted Manufacturer

Wire Weld, Plastic Strip, Paper Strip, Rolling Machine, Nail Making Machine

BESTEC

Verified & Trusted Manufacturer

Mold manufacturer, Gas spring for mold, Mold related standard parts and more

KUNWOO MACHINERY

Verified & Trusted Manufacturer

Rebar Processing Machine Manufacturer, Rebar Cutter, Rebar Bender, Rebar Ring Bender and more