Overview

- Summary

- NEYRET GROUP is a company specializing in the design and manufacturing of special assembly machines with over 30 years of experience. A leading designer and manufacturer of automatic assembly, control, and printing machines. Providing customized automation solutions for a wide range of industrial sectors including medical and pharma, perfume and cosmetics, personal care, automotive, electrical, and connectivity industries. Expertise in high-precision, high-speed assembly solutions utilizing both indexed motion and continuous motion technologies.NEYRET GROUP is a company specializing in the design and manufacturing of special assembly machines with over 30 years of experience. A leading designer and manufacturer of automatic assembly, control, and printing machines. Providing customized automation solutions for a wide range of industrial sectors including medical and pharma, perfume and cosmetics, personal care, automotive, electrical, and connectivity industries. Expertise in high-precision, high-speed assembly solutions utilizing both indexed motion and continuous motion technologies.

- Key Products/Technologies

- Flexible Machines: Flexible machines optimized for multi-variant assembly, capable of assembling up to 2500 products per hour through easily interchangeable tools.Flexible Machines: Flexible machines optimized for multi-variant assembly, capable of assembling up to 2500 products per hour through easily interchangeable tools.

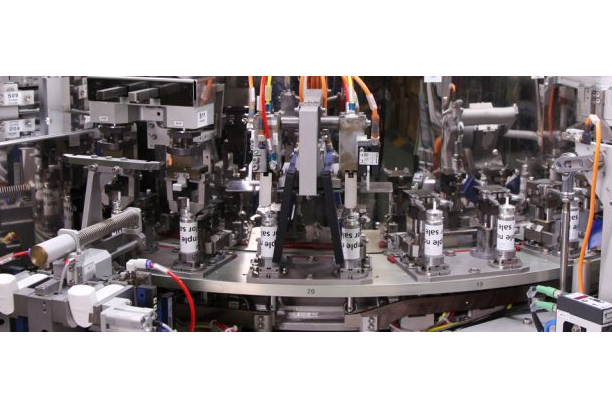

- Indexed Motion Machine: Indexed assembly machines based on rotary tables or linear conveyors, achieving speeds of 5 to 75 cycles per minute. Systems particularly suitable for complex processes requiring component immobility such as riveting, machining, and labeling. Capability to integrate various special processes including welding, gluing, vision inspection, leak testing, and laser marking.Indexed Motion Machine: Indexed assembly machines based on rotary tables or linear conveyors, achieving speeds of 5 to 75 cycles per minute. Systems particularly suitable for complex processes requiring component immobility such as riveting, machining, and labeling. Capability to integrate various special processes including welding, gluing, vision inspection, leak testing, and laser marking.

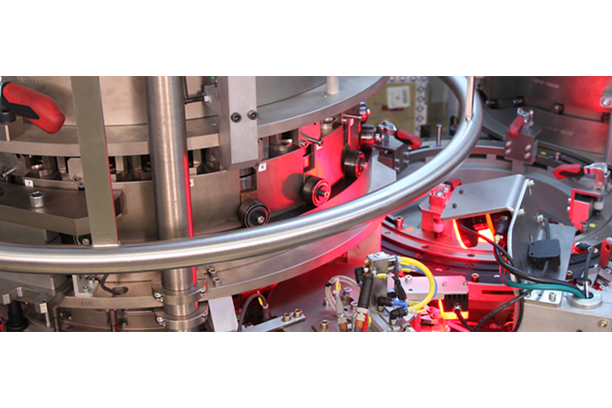

- Continuous Motion Machine: High-speed automation systems specialized for mass production, achieving assembly speeds of 150 to 1200 parts per minute. Primarily used for circular products, with technology to perform complex processes like screwing, gluing, and ultrasonic welding within a single process.Continuous Motion Machine: High-speed automation systems specialized for mass production, achieving assembly speeds of 150 to 1200 parts per minute. Primarily used for circular products, with technology to perform complex processes like screwing, gluing, and ultrasonic welding within a single process.

- Pilot Machines: Pilot machines utilized in clinical test stages, playing a role in de-risking critical steps of the assembly process in advance.Pilot Machines: Pilot machines utilized in clinical test stages, playing a role in de-risking critical steps of the assembly process in advance.

- Semi Automatic Machines: Semi-automatic machines suitable for low and medium production volumes, capable of assembling up to 800 products per hour.Semi Automatic Machines: Semi-automatic machines suitable for low and medium production volumes, capable of assembling up to 800 products per hour.

- Peripheral Systems: Integrated solutions for various feeding systems, palletizing, tray palletizers and depalletizers, and FIFO conveyors. Utilization of robots (XY, scara, delta type, 6-axis robots) for component feeding.Peripheral Systems: Integrated solutions for various feeding systems, palletizing, tray palletizers and depalletizers, and FIFO conveyors. Utilization of robots (XY, scara, delta type, 6-axis robots) for component feeding.

- Digital Printing Machines: Inkjet digital printing technology meeting stringent industrial requirements in the medical and food sectors, allowing quick changes and reduced downtime without printing plates.Digital Printing Machines: Inkjet digital printing technology meeting stringent industrial requirements in the medical and food sectors, allowing quick changes and reduced downtime without printing plates.

- Integrated Process Technologies: Extensive expertise in integrating a wide range of processes including mechanical assembly, cutting and forming, liquid feeding, various welding techniques, printing and marking, labeling, and precise quality testing. Capability to ensure 100% product conformity using 2D/3D vision systems and various sensors.Integrated Process Technologies: Extensive expertise in integrating a wide range of processes including mechanical assembly, cutting and forming, liquid feeding, various welding techniques, printing and marking, labeling, and precise quality testing. Capability to ensure 100% product conformity using 2D/3D vision systems and various sensors.

- Robotics: Robotic solutions integrated into the assembly machine flow or operating independently, utilized for small, delicate component assembly and "Pick and Place" operations.Robotics: Robotic solutions integrated into the assembly machine flow or operating independently, utilized for small, delicate component assembly and "Pick and Place" operations.

- Core Advantages

- Over 30 Years of Unique Expertise and Innovation: Rich experience and continuous technological innovation capabilities in specialized machine design and manufacturing for over three decades.Over 30 Years of Unique Expertise and Innovation: Rich experience and continuous technological innovation capabilities in specialized machine design and manufacturing for over three decades.

- Provision of Customer-Tailored Turnkey Solutions: Ability to provide fully customized automatic assembly and test machines, from design to installation and tuning, tailored to unique customer production requirements.Provision of Customer-Tailored Turnkey Solutions: Ability to provide fully customized automatic assembly and test machines, from design to installation and tuning, tailored to unique customer production requirements.

- Dual Expertise in Indexed and Continuous Motion Technologies: Mastery of both indexed motion for precise and complex assembly and continuous motion for high-volume, high-speed production, offering optimal automation solutions.Dual Expertise in Indexed and Continuous Motion Technologies: Mastery of both indexed motion for precise and complex assembly and continuous motion for high-volume, high-speed production, offering optimal automation solutions.

- Extensive Process Integration and Quality Assurance: Technical capability to integrate numerous processes such as mechanical assembly, control, printing, welding, gluing, and precise quality inspection into a single machine, ensuring 100% quality compliance.Extensive Process Integration and Quality Assurance: Technical capability to integrate numerous processes such as mechanical assembly, control, printing, welding, gluing, and precise quality inspection into a single machine, ensuring 100% quality compliance.

- Global Installation and Comprehensive After-Sales Service: A comprehensive customer support system including worldwide machine installation, user training, remote maintenance, and on-site expert assistance.Global Installation and Comprehensive After-Sales Service: A comprehensive customer support system including worldwide machine installation, user training, remote maintenance, and on-site expert assistance.

- FDA Compliance and Cleanroom Environment: Integration of FDA validation protocols for pharmaceutical and medical sector machines and capability for machine testing and validation in cleanroom environments.FDA Compliance and Cleanroom Environment: Integration of FDA validation protocols for pharmaceutical and medical sector machines and capability for machine testing and validation in cleanroom environments.

- Technological Leadership through Continuous R&D: Ongoing research and development activities to enhance adaptability in complex or micro-assembly fields and continuously provide innovative solutions.Technological Leadership through Continuous R&D: Ongoing research and development activities to enhance adaptability in complex or micro-assembly fields and continuously provide innovative solutions.

- Target Industrie

- Medical & Pharma: Assembly of drug delivery devices, injection systems, medical devices, containers, and packaging components.Medical & Pharma: Assembly of drug delivery devices, injection systems, medical devices, containers, and packaging components.

- Perfume & Cosmetic: Assembly of precision components such as perfume pumps and lipstick mechanisms.Perfume & Cosmetic: Assembly of precision components such as perfume pumps and lipstick mechanisms.

- Personal Care & Homecare: Automated production for personal hygiene products and household items.Personal Care & Homecare: Automated production for personal hygiene products and household items.

- Automotive: Assembly of automotive components including quick fuel connectors, micro-switches, and electrical relays.Automotive: Assembly of automotive components including quick fuel connectors, micro-switches, and electrical relays.

- Electrical & Connectivity: Assembly of electrical and electronic components such as circuit breakers, connectors, and photovoltaic panel connectors.Electrical & Connectivity: Assembly of electrical and electronic components such as circuit breakers, connectors, and photovoltaic panel connectors.

- Food: Automation solutions for the food industry.Food: Automation solutions for the food industry.

- Agriculture: Assembly of agricultural components such as irrigation drippers.Agriculture: Assembly of agricultural components such as irrigation drippers.

- Stationery & Textile Industry: Application in various industrial sectors including 4-color ballpoint pens and textile machine components.Stationery & Textile Industry: Application in various industrial sectors including 4-color ballpoint pens and textile machine components.

- Major Markets

- China (Sales and customer service through NAAM (Changzhou) Automation Ltd. sales subsidiary, with future plans for Southeast Asia expansion and local production)China (Sales and customer service through NAAM (Changzhou) Automation Ltd. sales subsidiary, with future plans for Southeast Asia expansion and local production)

- France (Headquarters and two main production sites)France (Headquarters and two main production sites)

- USA (Targeting local market development and high-tech machine production through its Franklin Automation subsidiary)USA (Targeting local market development and high-tech machine production through its Franklin Automation subsidiary)

- Certifications/Patents

- Capability to integrate FDA validation protocols for pharmaceutical and medical sector machines.Capability to integrate FDA validation protocols for pharmaceutical and medical sector machines.

- Operation of ISO8 cleanroom facilities at the Lagniel production site.Operation of ISO8 cleanroom facilities at the Lagniel production site.

- Industrial vision system integration technology to achieve 100% quality products.Industrial vision system integration technology to achieve 100% quality products.

- Proprietary technological mastery based on over 30 years of experience and innovation.Proprietary technological mastery based on over 30 years of experience and innovation.

- Track record of successfully delivering over 730 automation solutions worldwide.Track record of successfully delivering over 730 automation solutions worldwide.

Introduction

Key Products

Location

9 Rue Jules Verne, 69630 Chaponost, France

클릭하여 위치 살펴보기