This product is manufactured by

FIMOR POLYURETHANE

Manufacturer information

FIMOR POLYURETHANE

Verified & Trusted Manufacturer

Specialist of Cast Polyurethane Parts

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

FIMOR POLYURETHANE

Product Type

Machine

Brand

-

SKU

138978

Product Name

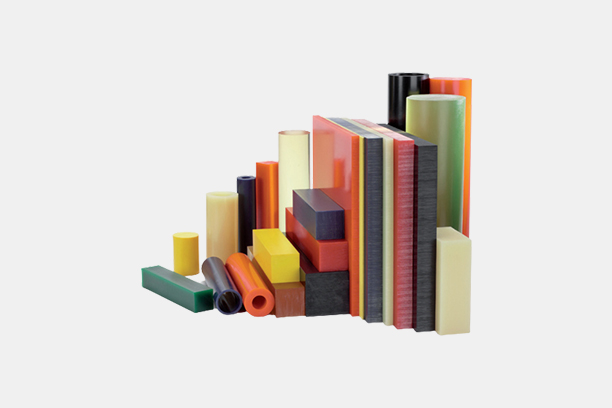

POLYURETHANE

Model Name

-

Size

-

Weight

-

Product Details

More products

There are no products listed yet.