This product is manufactured by

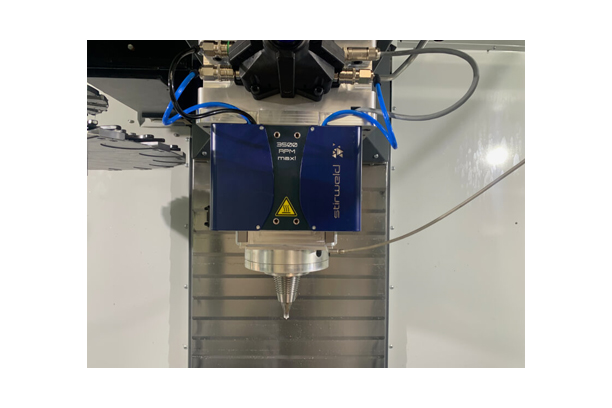

STIRWELD

Stirweld FSW Machine

Model Name

H15-01

Manufacturer information

STIRWELD

Verified & Trusted Manufacturer

FSW Supplier, FSM Heads, FSM Tools, FSW Accesories

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

STIRWELD

Product Type

Machine

Brand

-

SKU

138984

Product Name

Stirweld FSW Machine

Model Name

H15-01, D11-01

Size

-

Weight

-

Product Details