Overview

- Summary

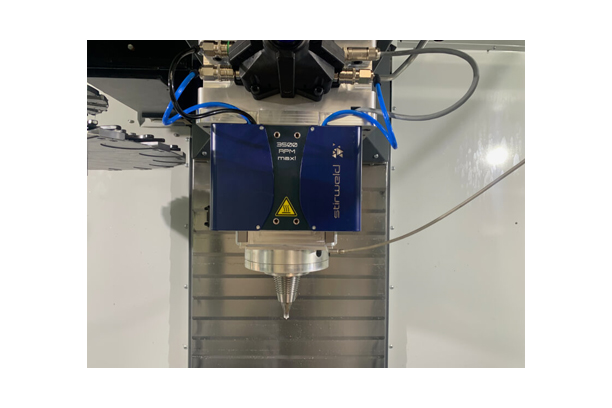

- STIRWELD, a French company founded in 2017, is a leading provider dedicated to democratizing Friction Stir Welding (FSW) technology globally. The company offers FSW heads seamlessly integrable with existing CNC machines and robotic spindles, a diverse range of FSW tools, accessories, and comprehensive industrial research and training services. Its core mission involves making FSW technology accessible at an affordable cost, thereby expanding market reach beyond traditionally expensive dedicated FSW equipment.STIRWELD, a French company founded in 2017, is a leading provider dedicated to democratizing Friction Stir Welding (FSW) technology globally. The company offers FSW heads seamlessly integrable with existing CNC machines and robotic spindles, a diverse range of FSW tools, accessories, and comprehensive industrial research and training services. Its core mission involves making FSW technology accessible at an affordable cost, thereby expanding market reach beyond traditionally expensive dedicated FSW equipment.

- Key Products/Technologies

- FSW Heads: A comprehensive range including Standard FSW Heads for CNC machines, Smart FSW Heads for advanced monitoring and welding automation, Retractable Pin FSW Heads for keyhole-free welding, and FSW Spindles for robotic arms in automated cells. These heads feature precise force control, real-time force tracking, efficient tool cooling, and optimal protection against mechanical stress and vibrations, ensuring compatibility with 99% of 3-axis, 4-axis, and 5-axis CNC machines.FSW Heads: A comprehensive range including Standard FSW Heads for CNC machines, Smart FSW Heads for advanced monitoring and welding automation, Retractable Pin FSW Heads for keyhole-free welding, and FSW Spindles for robotic arms in automated cells. These heads feature precise force control, real-time force tracking, efficient tool cooling, and optimal protection against mechanical stress and vibrations, ensuring compatibility with 99% of 3-axis, 4-axis, and 5-axis CNC machines.

- FSW Tools: Specialized tools for various materials such as aluminum alloys (1xxx, 2xxx, 3xxx, 5xxx, 6xxx, 7xxx series), aluminum-to-steel dissimilar joints, cast aluminum, and copper welding, designed for different thicknesses and joint configurations. These tools boast optimized geometries to minimize welding defects and maximize productivity, manufactured through mass production to maintain competitive pricing.FSW Tools: Specialized tools for various materials such as aluminum alloys (1xxx, 2xxx, 3xxx, 5xxx, 6xxx, 7xxx series), aluminum-to-steel dissimilar joints, cast aluminum, and copper welding, designed for different thicknesses and joint configurations. These tools boast optimized geometries to minimize welding defects and maximize productivity, manufactured through mass production to maintain competitive pricing.

- FSW Accessories: Offerings include a robust Standard Tool Holder compatible with all FSW heads and tools, an Automatic FSW Head Changer for quick transitions between FSW and machining, an FSW Smart Tool Holder for temperature measurement, and a Milling Add-On for cleaner weld finishes and post-welding machining capabilities.FSW Accessories: Offerings include a robust Standard Tool Holder compatible with all FSW heads and tools, an Automatic FSW Head Changer for quick transitions between FSW and machining, an FSW Smart Tool Holder for temperature measurement, and a Milling Add-On for cleaner weld finishes and post-welding machining capabilities.

- Complete FSW Machines: Integrated FSW solutions based on HAAS or Doosan CNC machines, with models such as H15-01 and D11-01. The H15-01 provides a thrust force of 15 kN, capable of welding up to 10mm thick in a single pass and 18mm in a double pass, while the D11-01 offers 11kN thrust force and 12,000 rpm speed, suitable for applications like heat sinks for e-mobility, rigid panels, and cold plates.Complete FSW Machines: Integrated FSW solutions based on HAAS or Doosan CNC machines, with models such as H15-01 and D11-01. The H15-01 provides a thrust force of 15 kN, capable of welding up to 10mm thick in a single pass and 18mm in a double pass, while the D11-01 offers 11kN thrust force and 12,000 rpm speed, suitable for applications like heat sinks for e-mobility, rigid panels, and cold plates.

- Industrial Research and Training Services: Comprehensive engineering support for FSW technology adoption and optimization, including industrial studies, part design and qualification, welding jig design, and welding parameter definition. The company also provides tailored FSW training programs, compliant with ISO 25239 standards, delivered on-site or via webinars, to cultivate FSW expertise.Industrial Research and Training Services: Comprehensive engineering support for FSW technology adoption and optimization, including industrial studies, part design and qualification, welding jig design, and welding parameter definition. The company also provides tailored FSW training programs, compliant with ISO 25239 standards, delivered on-site or via webinars, to cultivate FSW expertise.

- Core Advantages

- Accessibility and Cost-Effectiveness of FSW Technology: Providing solutions that drastically reduce the investment cost of FSW by integrating FSW heads into existing CNC machines or robots, eliminating the need for expensive dedicated FSW equipment. This approach facilitates cost-effective rapid prototyping, small-series manufacturing, and large-scale production.Accessibility and Cost-Effectiveness of FSW Technology: Providing solutions that drastically reduce the investment cost of FSW by integrating FSW heads into existing CNC machines or robots, eliminating the need for expensive dedicated FSW equipment. This approach facilitates cost-effective rapid prototyping, small-series manufacturing, and large-scale production.

- Technological Innovation and Continuous R&D: Possessing strong capabilities in developing innovative products such as the Smart FSW Head with advanced HMI for real-time monitoring and data management, and Retractable Pin technology for keyhole-free welding. The company dedicates at least 15% of its turnover to R&D and participates in European H2020 projects (FUN HEAD, RESURGAM) to remain at the forefront of technological advancements.Technological Innovation and Continuous R&D: Possessing strong capabilities in developing innovative products such as the Smart FSW Head with advanced HMI for real-time monitoring and data management, and Retractable Pin technology for keyhole-free welding. The company dedicates at least 15% of its turnover to R&D and participates in European H2020 projects (FUN HEAD, RESURGAM) to remain at the forefront of technological advancements.

- Broad Compatibility and Versatility: FSW heads designed for universal compatibility with 99% of 3-axis, 4-axis, or 5-axis CNC machines and high-payload robotic spindles, allowing flexible adaptation to diverse manufacturing environments. A wide range of FSW tools optimized for various materials, thicknesses, and joint configurations, including aluminum, copper, and dissimilar materials.Broad Compatibility and Versatility: FSW heads designed for universal compatibility with 99% of 3-axis, 4-axis, or 5-axis CNC machines and high-payload robotic spindles, allowing flexible adaptation to diverse manufacturing environments. A wide range of FSW tools optimized for various materials, thicknesses, and joint configurations, including aluminum, copper, and dissimilar materials.

- Comprehensive Technical Support and Expertise: Offering extensive industrial studies and design assistance, from initial part design to prototyping, clamping system design, welding parameter definition, and quality control. Providing ISO 25239 compliant on-site and webinar training programs to empower customers with FSW technical proficiency.Comprehensive Technical Support and Expertise: Offering extensive industrial studies and design assistance, from initial part design to prototyping, clamping system design, welding parameter definition, and quality control. Providing ISO 25239 compliant on-site and webinar training programs to empower customers with FSW technical proficiency.

- High Quality and Reliability: Adherence to ISO 9001:2015 quality management system and ISO 25239 FSW welding procedure standards, ensuring consistent product and service quality. Being an industrial member of TWI, the inventor of FSW, provides access to exclusive information on the latest FSW R&D innovations.High Quality and Reliability: Adherence to ISO 9001:2015 quality management system and ISO 25239 FSW welding procedure standards, ensuring consistent product and service quality. Being an industrial member of TWI, the inventor of FSW, provides access to exclusive information on the latest FSW R&D innovations.

- Global Market Expansion and Customer Proximity: Certified as an approved exporter, ensuring efficient and safe worldwide shipments. Establishing subsidiaries in Detroit, USA, and Germany, in addition to its French headquarters, to enhance customer proximity and provide swift support through a growing global network of distributors.Global Market Expansion and Customer Proximity: Certified as an approved exporter, ensuring efficient and safe worldwide shipments. Establishing subsidiaries in Detroit, USA, and Germany, in addition to its French headquarters, to enhance customer proximity and provide swift support through a growing global network of distributors.

- Target Industrie

- Aerospace Industry: Application of FSW technology for joining fuselage panels, wings, aircraft components, and high-value applications such as the Ariane 6 program.Aerospace Industry: Application of FSW technology for joining fuselage panels, wings, aircraft components, and high-value applications such as the Ariane 6 program.

- Automotive Industry: Utilization in manufacturing body panels, frames, engine components, battery trays, and heat exchangers, with increasing importance in e-mobility applications.Automotive Industry: Utilization in manufacturing body panels, frames, engine components, battery trays, and heat exchangers, with increasing importance in e-mobility applications.

- Railway Industry: FSW process application for welding train carriages and other railway components.Railway Industry: FSW process application for welding train carriages and other railway components.

- Shipbuilding Industry: Application of FSW technology for joining ship hulls and other marine structures.Shipbuilding Industry: Application of FSW technology for joining ship hulls and other marine structures.

- Energy Industry: Use of FSW in manufacturing energy-related components such as hydrogen storage tanks, liquid cold plates, and busbars.Energy Industry: Use of FSW in manufacturing energy-related components such as hydrogen storage tanks, liquid cold plates, and busbars.

- Metalworking Industry: Providing high-quality welding solutions through FSW technology across various metalworking applications.Metalworking Industry: Providing high-quality welding solutions through FSW technology across various metalworking applications.

- Defense Industry: Implementing FSW for assembling high-strength aluminum and advanced alloys, enabling faster and more reliable manufacturing in defense production.Defense Industry: Implementing FSW for assembling high-strength aluminum and advanced alloys, enabling faster and more reliable manufacturing in defense production.

- Construction Industry: Application of FSW technology for joining architectural panels and other building components.Construction Industry: Application of FSW technology for joining architectural panels and other building components.

- Consumer Electronics Industry: Utilization of FSW in the manufacturing of electronic devices like laptops and smartphones.Consumer Electronics Industry: Utilization of FSW in the manufacturing of electronic devices like laptops and smartphones.

- Medical and Telecommunications Industries: Specific applications of the FSW process in certain medical and telecommunications sectors.Medical and Telecommunications Industries: Specific applications of the FSW process in certain medical and telecommunications sectors.

- Major Markets

- Africa-wideAfrica-wide

- Asia-wideAsia-wide

- France (headquarters), Germany (office and distribution partner), Europe-wideFrance (headquarters), Germany (office and distribution partner), Europe-wide

- USA (subsidiary in Detroit, MI), North America-wideUSA (subsidiary in Detroit, MI), North America-wide

- South America-wideSouth America-wide

- Certifications/Patents

- ISO 9001:2015 Certification: A standardized quality management system certification for the design, manufacture, and sale of FSW tools/equipment, as well as customer training and technical support.ISO 9001:2015 Certification: A standardized quality management system certification for the design, manufacture, and sale of FSW tools/equipment, as well as customer training and technical support.

- ISO 25239 Standard Compliance: Strict adherence to guidelines for Friction Stir Welding of aluminum, covering weld joint design, qualification of welding operators and procedures, and quality/inspection requirements.ISO 25239 Standard Compliance: Strict adherence to guidelines for Friction Stir Welding of aluminum, covering weld joint design, qualification of welding operators and procedures, and quality/inspection requirements.

- AWS D17.3 Certification: Compliance with requirements for friction stir welding of aluminum aerospace hardware, including design of welded joints, qualification of procedures and operators, fabrication, and inspection.AWS D17.3 Certification: Compliance with requirements for friction stir welding of aluminum aerospace hardware, including design of welded joints, qualification of procedures and operators, fabrication, and inspection.

- ISO 14001 Process: Adherence to environmental management system processes aimed at reducing CO2 impact.ISO 14001 Process: Adherence to environmental management system processes aimed at reducing CO2 impact.

- FSW Head Patent: The FSW Head for CNC machine technology was patented in 2015 by SATT, a French governmental organization.FSW Head Patent: The FSW Head for CNC machine technology was patented in 2015 by SATT, a French governmental organization.

- Technical Strengths: Possession of proprietary technologies such as precise force control and recording from 1 to 25 kN, integrated cooling systems, spindle protection against loads and vibrations, real-time welding data display, and retractable pin technology for keyhole-free welding and variable sheet thickness assembly. Participation in European H2020 projects like "FUN HEAD" and "RESURGAM" further demonstrates innovation.Technical Strengths: Possession of proprietary technologies such as precise force control and recording from 1 to 25 kN, integrated cooling systems, spindle protection against loads and vibrations, real-time welding data display, and retractable pin technology for keyhole-free welding and variable sheet thickness assembly. Participation in European H2020 projects like "FUN HEAD" and "RESURGAM" further demonstrates innovation.

Introduction

Key Products

Location

4K Rue du Lieutenant Colonel Dubois, 35000 Rennes, France

클릭하여 위치 살펴보기