This product is manufactured by

SSCAN TECH

Manufacturer information

SSCAN TECH

Can manufacturing/processing machine manufacturer, Paint can, Aerosol, Drum and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

SSCAN TECH

Product Type

Machine

Brand

-

SKU

27435

Product Name

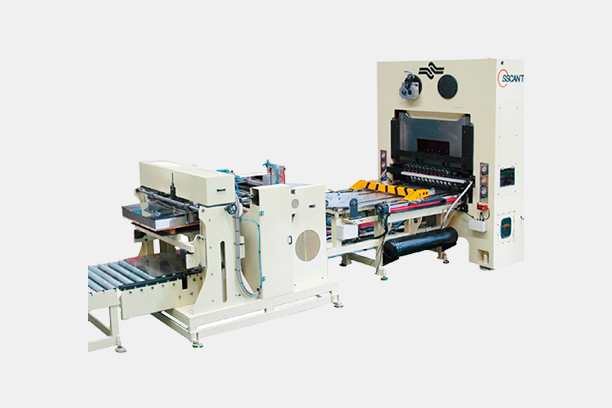

Lug Cap Making Line

Model Name

-

Size

-

Weight

-

Product Details

More products

Sheet Feeder PressSSC-MD1000

Auto Transfer PressTP-50T

Aerosol Transfer PressCTPD-110

Auto Feeding Tandem SlitterSSC-NTS

Double Die Press300DEP

Auto Scroll Shear M/CSSC-SC50

CNC Sheet Feeder PressSSC-SP-2000

Auto FlangerSSC-FL50

18L Square Can End Making Line

Auto Transfer PressTP-40T

20L Pail Can Body Making Line

Tuna Two Piece Can Body Making LineSSC-TN2

Vacuum Leakage TestorVT-600

Auto Round/Square Liner & Dryer

Aerosol Cone & Dome Making Line

1/4