This product is manufactured by

JINWOO ENGINEERING

Manufacturer information

JINWOO ENGINEERING

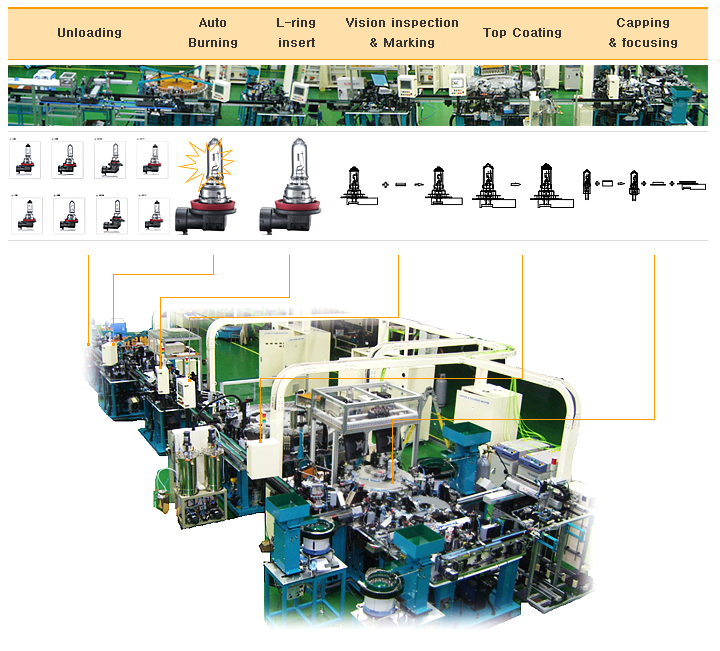

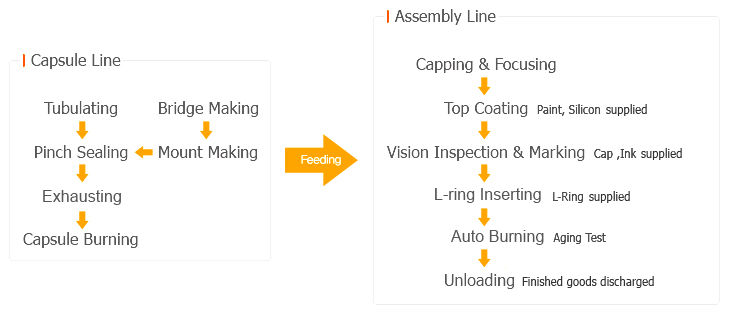

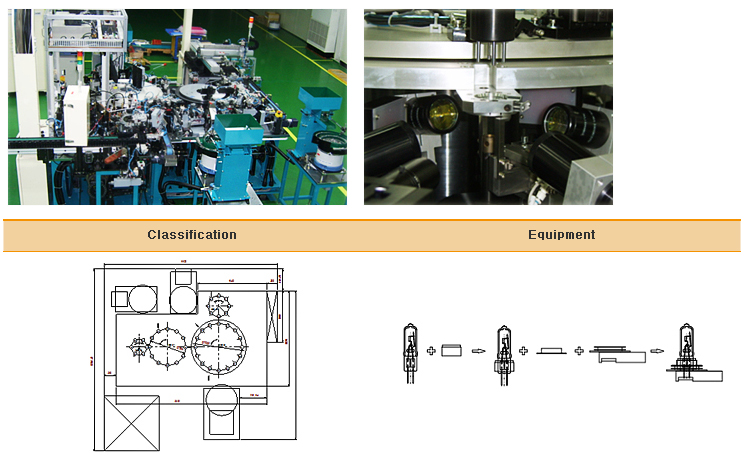

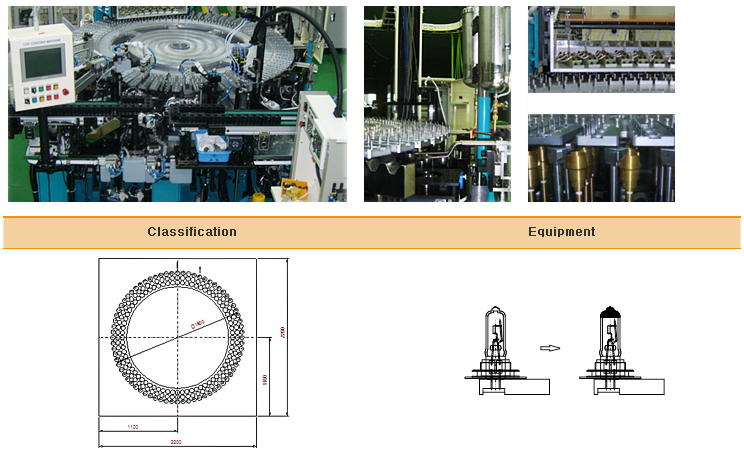

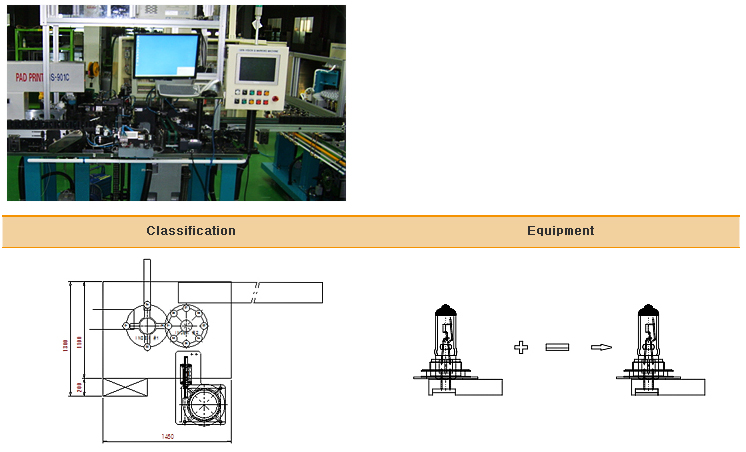

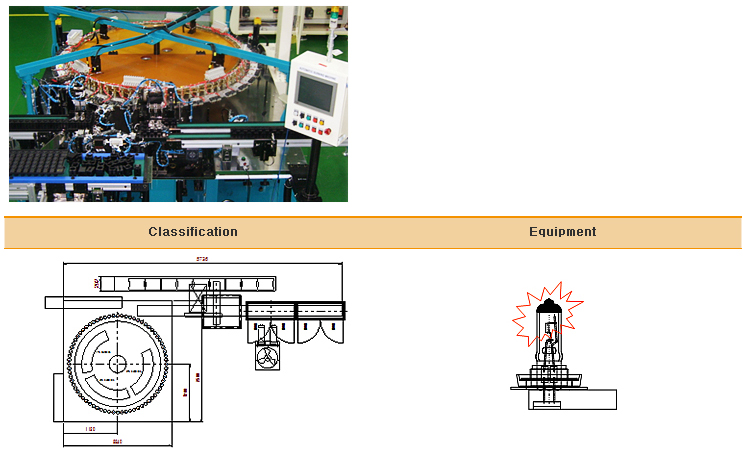

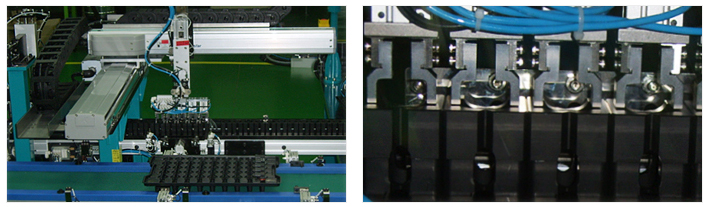

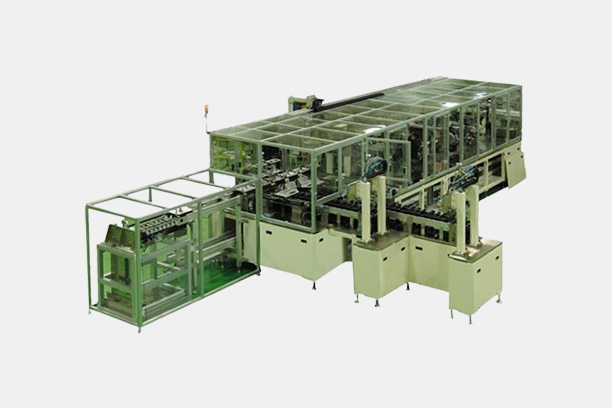

Manufacturer of Automobile facility, Super precision welding facility, Measuring inspection facility, Electron gun production facility

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

JINWOO ENGINEERING

Product Type

Machine

Brand

-

SKU

61

Product Name

Halogen Lamp

Model Name

H8, 9, 11, 16

Size

-

Weight

-

Product Details