This product is manufactured by

SEYANG MECHATRONICS

Manufacturer information

SEYANG MECHATRONICS

Rotary damper, Voltex tube, Air cooling machine, Air knife, Stopper cylinder, Buffer, In line filter

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

SEYANG MECHATRONICS

Product Type

Machine

Brand

-

SKU

139543

Product Name

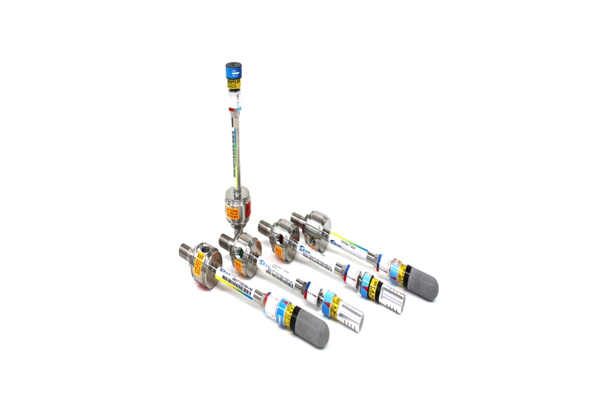

Vortex Hot Air Tool

Model Name

SMVHA-50008MNZ, SMVHA-50010MNZ, SMVHA-50015MNZ, SMVHA-50025MNZ, SMVHA-50035MNZ, SMVHA-50508MNZF, SMVHA-50510MNZF, SMVHA-50515MNZF, SMVHA-50525MNZF, SMVHA-50535MNZF

Size

-

Weight

-

Product Details

More products

디스크 댐퍼 (양방향성/고정식)FDT-47A-103, FDT-47A-163, FDT-47A-203, FDT-57A-303, FDT-57A-403, FDT-57A-503

Vortex Air Cool JacketSMVT1025CJ-CH, SMPVT-25

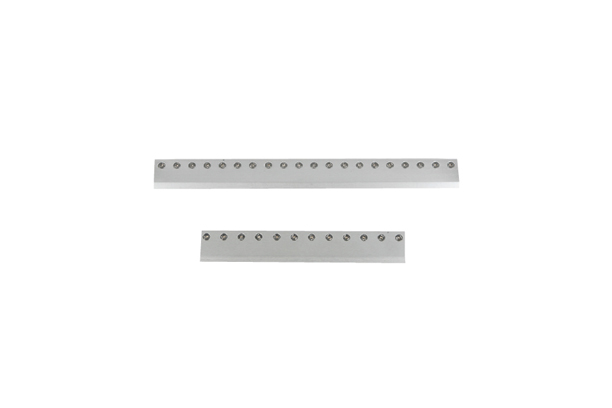

Vortex Air CurtainsSMVAC45003M, SMVAC45003MX, SMVAC45006M, SMVAC45006MX, SMVAC45012M, SMVAC45012MX, SMVAC45018M, SMVAC45018MX, SMVAC45024MSM, VAC45024MX, SMVAC45030M, SMVAC45030MX, SMVAC45036M, SMVAC45036MX, SMVAC40006M, SMVAC40006MX, SMVAC40012M, SMVAC40012MX, SMVAC40018M, SMVAC40018MX, SMVAC40024M, SMVAC40024MX, SMVAC40030M, SMVAC40030MX, SMVAC40036M, SMVAC40036MX

Vortex High Thrust JetsSMVJ60040M, SMVJ60044M

Vortex Cool ToolsSMVCT 30008M, SMVCT 30010M, SMVCT 30015M, SMVCT 30025M, SMVCT 30035M, SMVCT 30308M, SMVCT 30310M, SMVCT 30315M, SMVCT 30325M, SMVCT 30335M

Vortex Tube Magnet Base ⅡSMVT10008M-HM-MB-NZ, SMVT10010M-HM-MB-NZ, SMVT10015M-HM-MB-NZ, SMVT10025M-HM-MB-NZ, SMVT10035M-HM-MB-NZ

Vortex Hexagon CNC CoolersSMVCH60008M, SMVCH60010M, SMVCH60015M, SMVCH60025M, SMVCH60035M

Vortex CNC CoolersSMVCC20008M, SMVCC20108M, SMVCC20308M, SMVCC20508M, SMVCC20010M, SMVCC20110M, SMVCC20310M, SMVCC20510M, SMVCC20015M, SMVCC20115M, SMVCC20315M, SMVCC20515M, SMVCC20025M, SMVCC20125M, SMVCC20325M, SMVCC20525M, SMVCC20035M, SMVCC20135M, SMVCC20335M, SMVCC20535M

Vortex TubesSMVT10008M, SMVT10010M, SMVT10015M, SMVT10025M, SMVT10035M, SMVT10050M, SMVT10060M, SMVTFO10400M, SMVCM10000M, SMVHM10001M, SMVTG10002M, SMVTG10003M

산업용 충격 완충기 (다공오리피스 고정식)FW-1212L-C, FW-1515M, FW-2525M, FW-2530M

산업용 충격 완충기 (다공오리피스 고정식)FV-2008L-S, FV-2508L-S, FV-2708L-S

산업용 충격 완충기 (다공오리피스 고정식)FS-2006L-S, FS-2506L-S, FS-2706L-S

산업용 충격 완충기 (다공오리피스)FL-1214H, FL-1217H, FL-1620H

산업용 충격 완충기 (다공오리피스 고정식)FK-2016L, FK-2016M, FK-2016H, FK-2022L, FK-2022M, FK-2022H, FK-2050L-R, FK-2050M-R, FK-2050H-R, FK-2530L, FK-2530M, FK-2530H, FK-2540L, FK-2540M, FK-2540H, FK-2550L-R, FK-2550M-R, FK-2550H-R

아이솔레이터SWRI-5000400, SWRI-5000413, SWRI-5000475, SWRI-5000525, SWRI-5000565, SWRI-5000613, SWRI-5000710

1/4