This product is manufactured by

SEYANG MECHATRONICS

Manufacturer information

SEYANG MECHATRONICS

Rotary damper, Voltex tube, Air cooling machine, Air knife, Stopper cylinder, Buffer, In line filter

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

SEYANG MECHATRONICS

Product Type

Machine

Brand

-

SKU

139559

Product Name

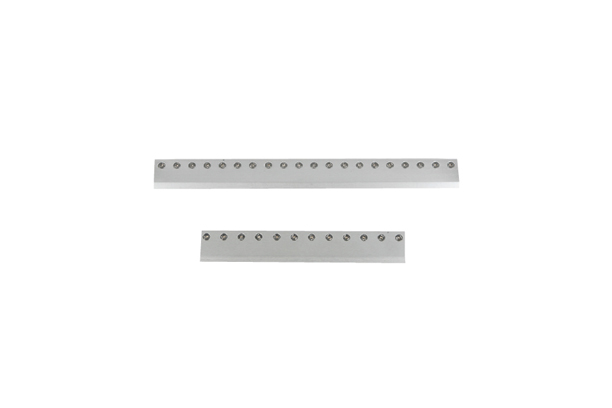

Vortex Air Curtains

Model Name

SMVAC45003M, SMVAC45003MX, SMVAC45006M, SMVAC45006MX, SMVAC45012M, SMVAC45012MX, SMVAC45018M, SMVAC45018MX, SMVAC45024MSM, VAC45024MX, SMVAC45030M, SMVAC45030MX, SMVAC45036M, SMVAC45036MX, SMVAC40006M, SMVAC40006MX, SMVAC40012M, SMVAC40012MX, SMVAC40018M, SMVAC40018MX, SMVAC40024M, SMVAC40024MX, SMVAC40030M, SMVAC40030MX, SMVAC40036M, SMVAC40036MX

Size

-

Weight

-

Product Details

More products

대형 로타베이터GMR245HK, GMR255HK, GMR265HK, GMR285HK

광폭 로타베이터GMR220HG, GMR240HG, GMR260HG, GMR280HG, GMR300HG

고상형 로타베이터NT200, NT205, NT210, NT215, NT220, NT230, NT240, NT250, NT260

소형 로타베이터MINI115, MINI125, MINI135, MINI145

Spade PlowGMP120, GMP170, GMP180, GMP240

HK 100-140HPGMR245HK, GMR255HK, GMR265HK, GMR285HK

제초기BY130, BY150, BY165, BY180

쟁기(심경) 로타베이터GMR145SK, GMR165SK, GMR185SK, GMR205SK

제주형 로타베이터NA165J, NA175J, NA185J, NT210J, NT215J, NT220J, NT230J, NT240J

진압기CP240, CP280, CR240, CR280, CRP240, CRP280, CRS240, CRS280

Mold Board PlowYS3B, YS3BL, YS4B, YS4BL, YS3DUP, YS4DUP

Offset Spade PlowGMP100A, GMP120A

Plant Machines

Digging Machines

HA 35-45HPGMR165HA, GMR175HA

HR 20-43HPGMR155HR, GMR165HR, GMR175HR

1/4