지금 보고 계신 제품의 제조사에요

신성정밀공업(주)

제품 상세 정보

이 기업의 다른 제품

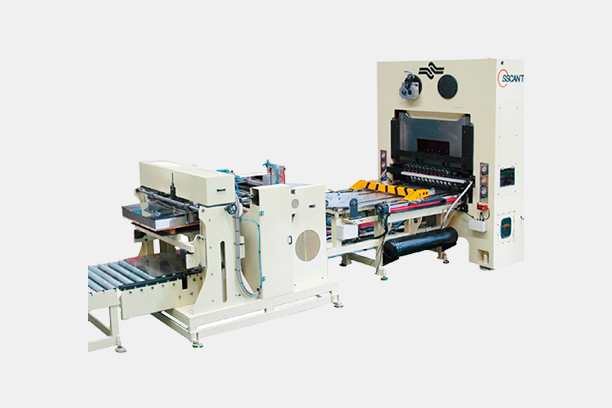

Sheet Feeder PressSSC-MD1000

Auto Transfer PressTP-50T

Aerosol Transfer PressCTPD-110

Auto Feeding Tandem SlitterSSC-NTS

Double Die Press300DEP

Auto Scroll Shear M/CSSC-SC50

CNC Sheet Feeder PressSSC-SP-2000

Auto FlangerSSC-FL50

18L Square Can End Making Line

Auto Transfer PressTP-40T

20L Pail Can Body Making Line

Vacuum Leakage TestorVT-600

Auto Round/Square Liner & Dryer

Aerosol Cone & Dome Making Line

Lug Cap Making Line

1/4