Overview

- Summary

- Sony Electronics of Korea Corporation is a subsidiary of global company Sony Corporation, specializing in vision inspection, smart factory construction, and high-speed, high-precision automation equipment manufacturing. The company leverages its expertise in ultra-precision component production and production automation to provide customized automation solutions across various industrial sectors. Key offerings include pre-adjustment and inspection equipment for electronic products, the ez-VISION vision system, and major process equipment for secondary batteries.Sony Electronics of Korea Corporation is a subsidiary of global company Sony Corporation, specializing in vision inspection, smart factory construction, and high-speed, high-precision automation equipment manufacturing. The company leverages its expertise in ultra-precision component production and production automation to provide customized automation solutions across various industrial sectors. Key offerings include pre-adjustment and inspection equipment for electronic products, the ez-VISION vision system, and major process equipment for secondary batteries.

- Key Products/Technologies

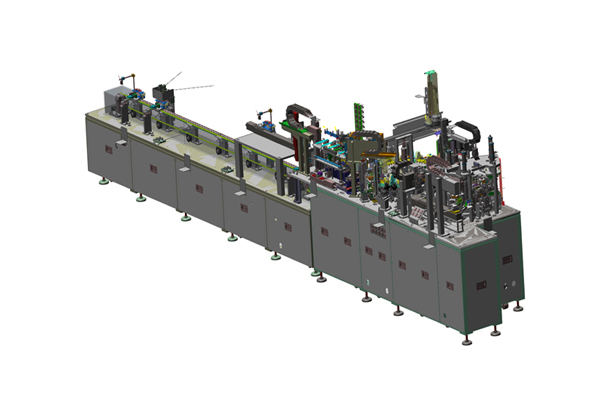

- Electronics Pre-Adjustment & Inspection Line: An automated assembly and inspection line designed for electronic products, performing firmware recording and performance tests after assembly, with an equipment cycle time of 15 seconds.Electronics Pre-Adjustment & Inspection Line: An automated assembly and inspection line designed for electronic products, performing firmware recording and performance tests after assembly, with an equipment cycle time of 15 seconds.

- ez-VISION: A machine vision software developed by Sony Electronics of Korea, utilizing the National Instruments Library for PC-based vision inspection. It offers diverse functionalities such as pattern matching, edge detection, length measurement, histogram analysis, 1D/2D barcode and OCR recognition, circular component inspection, color pattern matching, contour detection, and Blob inspection.ez-VISION: A machine vision software developed by Sony Electronics of Korea, utilizing the National Instruments Library for PC-based vision inspection. It offers diverse functionalities such as pattern matching, edge detection, length measurement, histogram analysis, 1D/2D barcode and OCR recognition, circular component inspection, color pattern matching, contour detection, and Blob inspection.

- Non-woven Fabric Attach Equipment: Part of the key process equipment for secondary batteries, featuring non-woven fabric attachment technology.Non-woven Fabric Attach Equipment: Part of the key process equipment for secondary batteries, featuring non-woven fabric attachment technology.

- Electrolytic Liquid Injection Equipment: Automated equipment for injecting and sealing electrolytic liquid, included in the major process equipment for secondary batteries.Electrolytic Liquid Injection Equipment: Automated equipment for injecting and sealing electrolytic liquid, included in the major process equipment for secondary batteries.

- Assembly Equipment: Includes custom assembly solutions like automatic USB charger assembly equipment for automotive (cycle time 10 sec/unit, 95%+ utilization, 1 operator, 14 models supported), automatic cooling fin assembly equipment for automotive (cycle time 18 sec/unit, 95%+ utilization, 1 operator, multi-model support), and small medical device assembly equipment (cycle time 8 sec/unit, 90%+ utilization, 6 operators).Assembly Equipment: Includes custom assembly solutions like automatic USB charger assembly equipment for automotive (cycle time 10 sec/unit, 95%+ utilization, 1 operator, 14 models supported), automatic cooling fin assembly equipment for automotive (cycle time 18 sec/unit, 95%+ utilization, 1 operator, multi-model support), and small medical device assembly equipment (cycle time 8 sec/unit, 90%+ utilization, 6 operators).

- Aluminum Thin Film Forming Equipment: A key process equipment for secondary batteries, incorporating aluminum thin film forming technology.Aluminum Thin Film Forming Equipment: A key process equipment for secondary batteries, incorporating aluminum thin film forming technology.

- Deformed Parts Stick Feeder for High-Speed Mounting & Bowl Feeder: Feeding devices for deformed parts used in high-speed mounting processes.Deformed Parts Stick Feeder for High-Speed Mounting & Bowl Feeder: Feeding devices for deformed parts used in high-speed mounting processes.

- Index Type Automatic Assembly Equipment: An automated assembly system applying insulation tape adhesion technology, type welding technology, label bonding technology, and characteristic inspection.Index Type Automatic Assembly Equipment: An automated assembly system applying insulation tape adhesion technology, type welding technology, label bonding technology, and characteristic inspection.

- Automatic Packing Machine of Finished Products: Equipment for automated packaging of finished goods.Automatic Packing Machine of Finished Products: Equipment for automated packaging of finished goods.

- Robot-Utilizing Image Inspection: A smart factory-compatible system employing multi-joint robots to change inspection directions based on products and inspection requirements, performing dimensional, shape, color, print status, and surface image inspections.Robot-Utilizing Image Inspection: A smart factory-compatible system employing multi-joint robots to change inspection directions based on products and inspection requirements, performing dimensional, shape, color, print status, and surface image inspections.

- Core Advantages

- Leveraging Sony Group's Technology and Know-how: As a 100% subsidiary of Sony, the company has approximately 20 years of experience in developing and supplying automated production equipment for headphones, optical devices, miniaturized semiconductors, mobile phone displays, and beam projectors to Sony factories worldwide.Leveraging Sony Group's Technology and Know-how: As a 100% subsidiary of Sony, the company has approximately 20 years of experience in developing and supplying automated production equipment for headphones, optical devices, miniaturized semiconductors, mobile phone displays, and beam projectors to Sony factories worldwide.

- Proprietary Design and Automation Equipment Manufacturing Capability: The only Sony overseas factory with an integrated production system from product design to shipment, having independently designed and produced various products like cassette tape recorders, CD players, car stereos, wireless headphones, mini-components, and DVD players since the 1990s.Proprietary Design and Automation Equipment Manufacturing Capability: The only Sony overseas factory with an integrated production system from product design to shipment, having independently designed and produced various products like cassette tape recorders, CD players, car stereos, wireless headphones, mini-components, and DVD players since the 1990s.

- Smart Factory Solution Competence: Development of core smart factory technologies such as image processing vision systems, process monitoring software, and predictive management systems, contributing to customer productivity improvement and quality control.Smart Factory Solution Competence: Development of core smart factory technologies such as image processing vision systems, process monitoring software, and predictive management systems, contributing to customer productivity improvement and quality control.

- Expertise in Precision Optics and Semiconductor Fields: A key Sony subsidiary leading the global market in ultra-precision component production (e.g., laser diodes, pico projector modules) and optical pick-up (OP) devices. Possessing precision optical assembly and adjustment technology, and semiconductor die bonding equipment development technology.Expertise in Precision Optics and Semiconductor Fields: A key Sony subsidiary leading the global market in ultra-precision component production (e.g., laser diodes, pico projector modules) and optical pick-up (OP) devices. Possessing precision optical assembly and adjustment technology, and semiconductor die bonding equipment development technology.

- Provision of Customized Solutions for Diverse Industries: Actively engaged in manufacturing and selling custom automation equipment for non-Sony group manufacturing clients in China, Singapore, and Korea, demonstrating capabilities in designing and producing optimized equipment for various industries including automotive parts, medical devices, and secondary batteries.Provision of Customized Solutions for Diverse Industries: Actively engaged in manufacturing and selling custom automation equipment for non-Sony group manufacturing clients in China, Singapore, and Korea, demonstrating capabilities in designing and producing optimized equipment for various industries including automotive parts, medical devices, and secondary batteries.

- Target Industrie

- Electronics Manufacturing Industry: Automation and inspection line construction for various electronic products such as headphones, optical devices, miniaturized semiconductors, mobile phone displays, and beam projectors.Electronics Manufacturing Industry: Automation and inspection line construction for various electronic products such as headphones, optical devices, miniaturized semiconductors, mobile phone displays, and beam projectors.

- Automotive Parts Manufacturing Industry: Development of assembly and inspection lines for automotive parts, including automatic USB charger assembly equipment and automatic cooling fin assembly equipment.Automotive Parts Manufacturing Industry: Development of assembly and inspection lines for automotive parts, including automatic USB charger assembly equipment and automatic cooling fin assembly equipment.

- Medical Device Manufacturing Industry: Production of cell sorting chips for medical use and design/manufacturing of production equipment for medical devices.Medical Device Manufacturing Industry: Production of cell sorting chips for medical use and design/manufacturing of production equipment for medical devices.

- Secondary Battery Manufacturing Industry: Manufacturing of key process equipment for secondary batteries, including electrolytic liquid injectors, assembly machines, non-woven fabric attach equipment, and thin-film forming machines.Secondary Battery Manufacturing Industry: Manufacturing of key process equipment for secondary batteries, including electrolytic liquid injectors, assembly machines, non-woven fabric attach equipment, and thin-film forming machines.

- Major Markets

- China, Singapore, JapanChina, Singapore, Japan

- EuropeEurope

- United StatesUnited States

- Certifications/Patents

- Awarded the Silver Tower Order of Industrial Service Merit on Trade Day in November 2001.Awarded the Silver Tower Order of Industrial Service Merit on Trade Day in November 2001.

- Received the 'Billion Dollar Export Tower' award on Trade Day in 2001.Received the 'Billion Dollar Export Tower' award on Trade Day in 2001.

- Selected as an 'Excellent Company for New Labor-Management Culture' by the Ministry of Labor in the second half of 2002.Selected as an 'Excellent Company for New Labor-Management Culture' by the Ministry of Labor in the second half of 2002.

- Possession of core technologies including image processing (vision) software development, precision optical assembly and adjustment, semiconductor die bonding equipment development, multi-joint robot application, Low Cost PLR (Parallel Link Robot) technology, smart factory data and process management technology, automotive component assembly and inspection line development technology, and secondary battery key process equipment manufacturing technology.Possession of core technologies including image processing (vision) software development, precision optical assembly and adjustment, semiconductor die bonding equipment development, multi-joint robot application, Low Cost PLR (Parallel Link Robot) technology, smart factory data and process management technology, automotive component assembly and inspection line development technology, and secondary battery key process equipment manufacturing technology.

Introduction

Key Products

Location

76 Jayumuyeok 2-gil, Masanhoewon-gu, Changwon-si, Gyeongsangnam-do, South Korea

클릭하여 위치 살펴보기