This product is manufactured by

STANDARD INDUSTRIE INTERNATIONAL

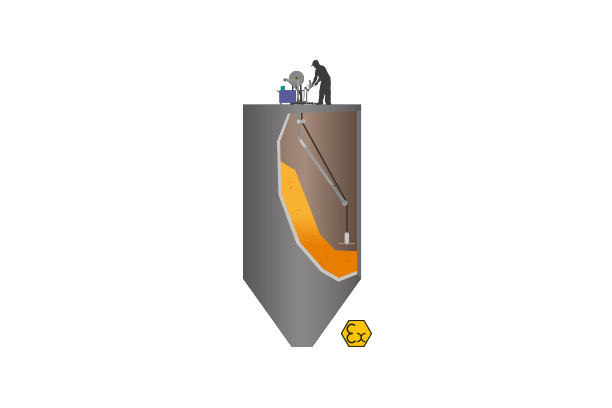

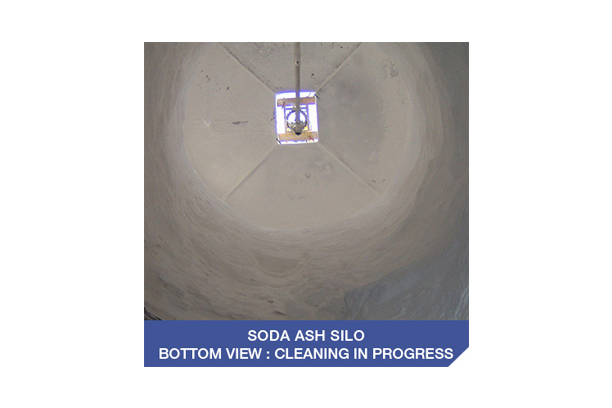

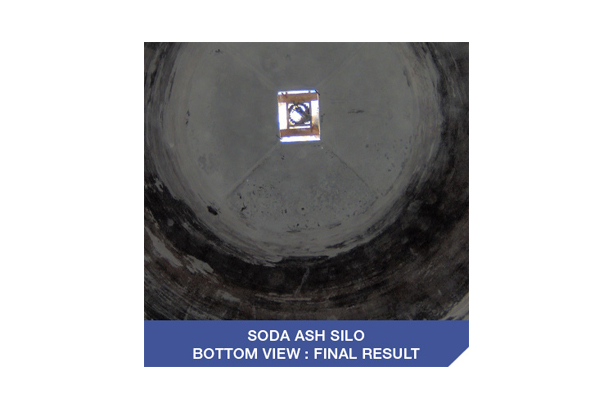

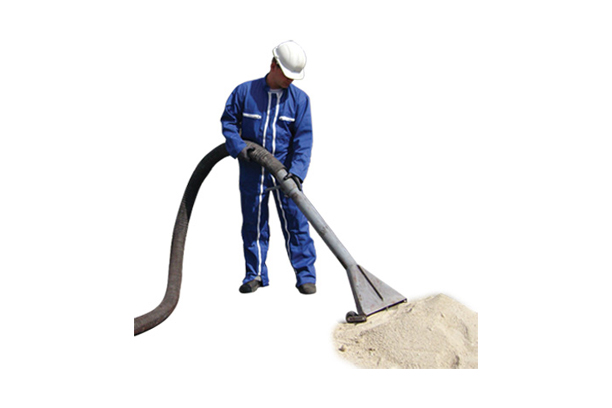

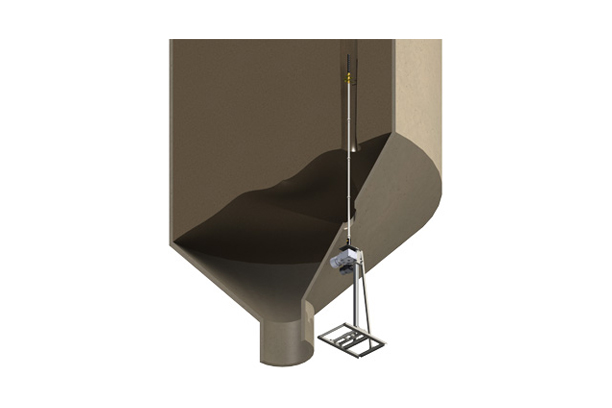

Silo and Hopper Cleaning Service

Model Name

GIRONET

Manufacturer information

STANDARD INDUSTRIE INTERNATIONAL

Verified & Trusted Manufacturer

Blockage & Build Up Removal, Industrial Vacuum Cleaning, Conveyor Belt Optimisation and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

STANDARD INDUSTRIE INTERNATIONAL

Product Type

Machine

Brand

-

SKU

137858

Product Name

Silo and Hopper Cleaning Service

Model Name

GIRONET

Size

-

Weight

-

Product Details

More products

Mobile Vacuum Cleaning UnitGAD

Rubber Balls

SOLIGOM® Rubber Bucket

Rubber Obturator

Vacuum Cleaning

PowernetPowernet

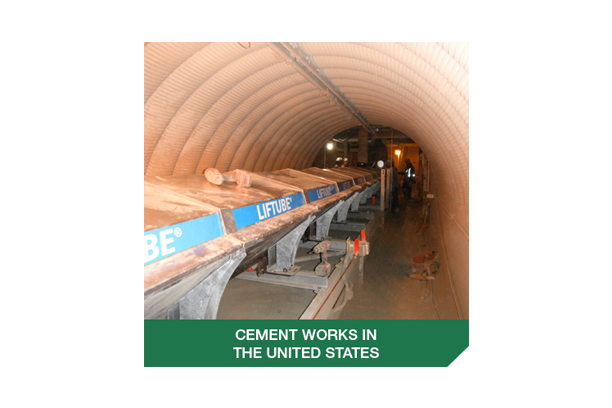

LIFTUBE® Conveyor Belt Skirting

Industrial Dust Collectors, Pre-separators

Industrial Vacuum CleanerPAD

Mobile Vacuum Cleaning StationSAM

Industrial Vacuum CleanerINC

UMA CompactUMA

Valnet Vacuum VehicleVALNET

MACSYS wireless

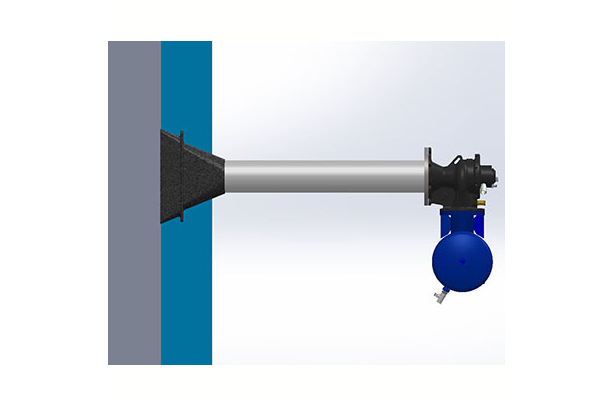

Deflector

1/4