Overview

- Summary

- STANDARD INDUSTRIE International, established in 1978, is a specialized company in the design and manufacture of equipment for the safe and environmentally friendly handling of powdery and bulk products. The company provides solutions aimed at optimizing the performance of production tools and reducing operating and maintenance costs. With four core areas of expertise, including blockage and build-up removal, industrial vacuum cleaning, conveyor belt optimization, and silo and hopper cleaning services, the company contributes to various industries. Through its global presence and innovative technological capabilities, the company focuses on enhancing customer productivity and establishing safe working environmentsSTANDARD INDUSTRIE International, established in 1978, is a specialized company in the design and manufacture of equipment for the safe and environmentally friendly handling of powdery and bulk products. The company provides solutions aimed at optimizing the performance of production tools and reducing operating and maintenance costs. With four core areas of expertise, including blockage and build-up removal, industrial vacuum cleaning, conveyor belt optimization, and silo and hopper cleaning services, the company contributes to various industries. Through its global presence and innovative technological capabilities, the company focuses on enhancing customer productivity and establishing safe working environments

- Key Products/Technologies

- The AIRCHOC® Air Blaster is an air cannon system effectively removing blockages and build-ups within silos and hoppers. The MACSYS Wireless multi-output air cannon utilizes wireless control to address blockages at multiple points simultaneously. The AIRCHOC® Maintenance Program is a preventive system minimizing the risk of production stoppages and enabling rapid maintenanceThe AIRCHOC® Air Blaster is an air cannon system effectively removing blockages and build-ups within silos and hoppers. The MACSYS Wireless multi-output air cannon utilizes wireless control to address blockages at multiple points simultaneously. The AIRCHOC® Maintenance Program is a preventive system minimizing the risk of production stoppages and enabling rapid maintenance

- Industrial vacuum cleaning equipment includes various models such as VALNET, UMA Compact, INC, GAD, SAM, PAD, Pre-separators, Industrial Dust Collectors, and Mobile Vacuum Cleaning Stations. These machines offer a power range from 5kW to 300kW (or 5 to 300 HP) and are available in electric or diesel-powered configurations, including fixed, mobile, and truck-mounted units, providing solutions for cleaning, pumping, and recycling needsIndustrial vacuum cleaning equipment includes various models such as VALNET, UMA Compact, INC, GAD, SAM, PAD, Pre-separators, Industrial Dust Collectors, and Mobile Vacuum Cleaning Stations. These machines offer a power range from 5kW to 300kW (or 5 to 300 HP) and are available in electric or diesel-powered configurations, including fixed, mobile, and truck-mounted units, providing solutions for cleaning, pumping, and recycling needs

- The LIFTUBE® Conveyor Belt Skirting is an innovative system optimizing the sealing of conveyor belts. This patented system effectively reduces dust emissions, enhances safety, and lowers maintenance costsThe LIFTUBE® Conveyor Belt Skirting is an innovative system optimizing the sealing of conveyor belts. This patented system effectively reduces dust emissions, enhances safety, and lowers maintenance costs

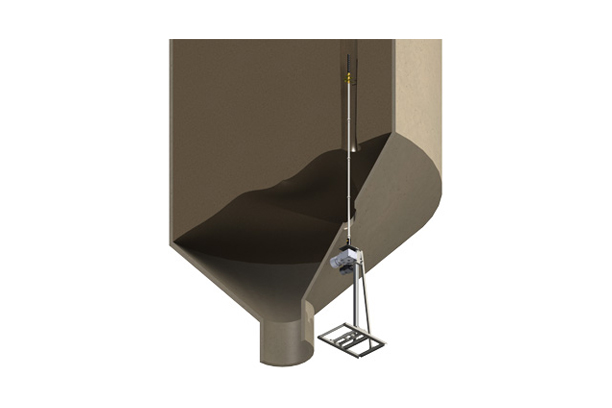

- Silo and Hopper Cleaning Services utilize POWERNET and GIRONET equipment to perform safe cleaning and vacuuming of storage units without human intervention. This service has a proven track record in solving silo blockage issues and restoring storage capacity in the glass industrySilo and Hopper Cleaning Services utilize POWERNET and GIRONET equipment to perform safe cleaning and vacuuming of storage units without human intervention. This service has a proven track record in solving silo blockage issues and restoring storage capacity in the glass industry

- In the transport, screening, and flow sector, products like Rubber Obturator, Rubber Balls, and SOLIGOM® Rubber Bucket are provided. These products support the smooth transport, screening, and flow of bulk powdery materials, alongside the capability for manufacturing custom molded rubber partsIn the transport, screening, and flow sector, products like Rubber Obturator, Rubber Balls, and SOLIGOM® Rubber Bucket are provided. These products support the smooth transport, screening, and flow of bulk powdery materials, alongside the capability for manufacturing custom molded rubber parts

- Core Advantages

- Over 40 years of expertise and continuous technological innovation in the field of powdery and bulk product handling equipment, starting with the first AIRCHOC® air cannon patent in 1978. The company consistently provides cutting-edge and efficient equipment through ongoing research and developmentOver 40 years of expertise and continuous technological innovation in the field of powdery and bulk product handling equipment, starting with the first AIRCHOC® air cannon patent in 1978. The company consistently provides cutting-edge and efficient equipment through ongoing research and development

- The ability to offer customized solutions for various types of blockages and build-up problems, coupled with a wide range of industrial vacuum equipment from 5kW to 300kW, ensures optimized solutions tailored to specific customer requirements. A deep understanding of individual industrial processes enables the provision of technically and economically optimized solutionsThe ability to offer customized solutions for various types of blockages and build-up problems, coupled with a wide range of industrial vacuum equipment from 5kW to 300kW, ensures optimized solutions tailored to specific customer requirements. A deep understanding of individual industrial processes enables the provision of technically and economically optimized solutions

- Contribution to customer productivity enhancement through proprietary methodologies and the patented LIFTUBE® system, which optimizes the performance of production tools and reduces operating and maintenance costs. Preventive maintenance solutions like the AIRCHOC® Maintenance Program prevent production stoppages and maximize efficiencyContribution to customer productivity enhancement through proprietary methodologies and the patented LIFTUBE® system, which optimizes the performance of production tools and reduces operating and maintenance costs. Preventive maintenance solutions like the AIRCHOC® Maintenance Program prevent production stoppages and maximize efficiency

- A global presence with subsidiaries in Europe, South Africa, China, Canada, Mexico, and the USA, supported by an extensive export sales network covering Eastern Europe, Asia, Central Africa, the Middle East, Maghreb, and Sub-Saharan Africa. Seven sales teams and 50 representatives ensure international customer support and service delivery capabilitiesA global presence with subsidiaries in Europe, South Africa, China, Canada, Mexico, and the USA, supported by an extensive export sales network covering Eastern Europe, Asia, Central Africa, the Middle East, Maghreb, and Sub-Saharan Africa. Seven sales teams and 50 representatives ensure international customer support and service delivery capabilities

- A strong focus on designing equipment for safe and environmentally friendly handling of bulk products, ensuring a healthy environment for operators and providing plant safety systems. The development of equipment such as GIRONET and LIFTUBE supports safe handling during production and maintenance operationsA strong focus on designing equipment for safe and environmentally friendly handling of bulk products, ensuring a healthy environment for operators and providing plant safety systems. The development of equipment such as GIRONET and LIFTUBE supports safe handling during production and maintenance operations

- Attainment of ISO 9001 (quality management) and ISO 45001 (occupational health and safety management) international standard certifications, guaranteeing product and service reliability. Various product certifications, including ATEX, CE, UL, ASME, GOST R, and CSA, align with market regulations, facilitating global market entryAttainment of ISO 9001 (quality management) and ISO 45001 (occupational health and safety management) international standard certifications, guaranteeing product and service reliability. Various product certifications, including ATEX, CE, UL, ASME, GOST R, and CSA, align with market regulations, facilitating global market entry

- Target Industrie

- In cement plants, solutions are provided for removing sand and concrete blockages within storage units and cleaning gas pipesIn cement plants, solutions are provided for removing sand and concrete blockages within storage units and cleaning gas pipes

- For the glass industry, air cannon solutions are applied to eliminate blockages and concretions in storage units, batch loading, and preparation processesFor the glass industry, air cannon solutions are applied to eliminate blockages and concretions in storage units, batch loading, and preparation processes

- In mines and quarries, air cannon cleaning solutions are utilized for removing material deposits, blockages, and build-ups such as sand, aggregate, or clayIn mines and quarries, air cannon cleaning solutions are utilized for removing material deposits, blockages, and build-ups such as sand, aggregate, or clay

- Industrial cleaning solutions are offered for waste treatment plants to remove blockages and concretions present in storage unitsIndustrial cleaning solutions are offered for waste treatment plants to remove blockages and concretions present in storage units

- Power plants benefit from cleaning services for ash, lime, gypsum, and vegetable matter used to feed biomass boilersPower plants benefit from cleaning services for ash, lime, gypsum, and vegetable matter used to feed biomass boilers

- In the food industry, solutions are applied for removing material deposits like sugar, soy, or flour in fluidizing feed or food production processesIn the food industry, solutions are applied for removing material deposits like sugar, soy, or flour in fluidizing feed or food production processes

- Cleaning solutions are provided for the steel industry to eliminate material deposits, blockages, and concretions in storage units and gas and dust treatment areasCleaning solutions are provided for the steel industry to eliminate material deposits, blockages, and concretions in storage units and gas and dust treatment areas

- The plaster industry utilizes services for cleaning plaster crusts in silos or for vacuum cleaning operationsThe plaster industry utilizes services for cleaning plaster crusts in silos or for vacuum cleaning operations

- Diverse bulk material handling solutions are also applied in the wood industry and paper/cardboard industryDiverse bulk material handling solutions are also applied in the wood industry and paper/cardboard industry

- Solutions are extended to various industrial sectors, including cleaning fertilizer manufacturing facilities and carbonate conveyors in chemical plantsSolutions are extended to various industrial sectors, including cleaning fertilizer manufacturing facilities and carbonate conveyors in chemical plants

- Major Markets

- South Africa, Central Africa, Maghreb, Sub-Saharan AfricaSouth Africa, Central Africa, Maghreb, Sub-Saharan Africa

- China, Southeast Asia, Singapore (liaison office), Middle EastChina, Southeast Asia, Singapore (liaison office), Middle East

- France, Morocco (Maghreb), Eastern European countriesFrance, Morocco (Maghreb), Eastern European countries

- Canada, USA, MexicoCanada, USA, Mexico

- Certifications/Patents

- Hervé Simoëns obtained the first patent for the AIRCHOC® air cannon in 1978. The company holds patents for the LIFTUBE® system, which optimizes conveyor belt sealingHervé Simoëns obtained the first patent for the AIRCHOC® air cannon in 1978. The company holds patents for the LIFTUBE® system, which optimizes conveyor belt sealing

- Maintenance of ISO 9001 quality management system certification since 1994. Attainment of ISO 45001 occupational health and safety management system certification since 2021. CE Mark certification for entry into the European Union market. ATEX certification for safe equipment use in potentially explosive atmospheres. UL and CSA certifications for compliance with US and Canadian market standards. ASME certification for pressure equipment manufacturing methods. GOST R certification for compliance with safety and quality requirements of the Russian FederationMaintenance of ISO 9001 quality management system certification since 1994. Attainment of ISO 45001 occupational health and safety management system certification since 2021. CE Mark certification for entry into the European Union market. ATEX certification for safe equipment use in potentially explosive atmospheres. UL and CSA certifications for compliance with US and Canadian market standards. ASME certification for pressure equipment manufacturing methods. GOST R certification for compliance with safety and quality requirements of the Russian Federation

Introduction

Key Products

Location

139 Rue du Luxembourg, 59100 Roubaix, France

클릭하여 위치 살펴보기