This product is manufactured by

KMJ

Co2 Nozzle Cleaner

Model Name

KA-NA-01

Manufacturer information

KMJ

Resistance welding machine, Cable for welding, Special alloy, Electric control device, Arc parts, Welding apparatus

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

KMJ

Product Type

Machine

Brand

-

SKU

142185

Product Name

Co2 Nozzle Cleaner

Model Name

KA-NA-01

Size

-

Weight

-

Product Details

More products

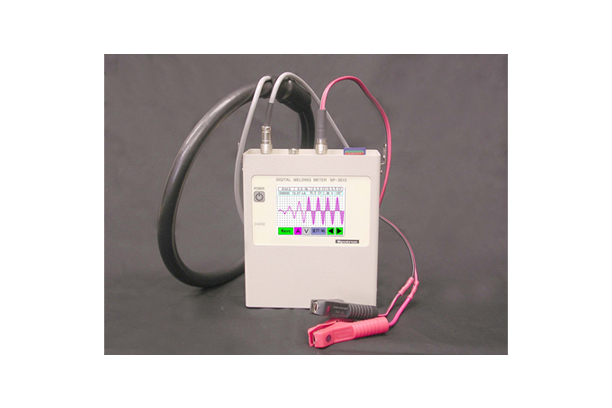

Weld Breakdown TesterWBT-300, WBT-500

Nut & Bolt ManagerKBM-001, KBM-002

Automatic Nut&Bolt FeederKR-NF-01, KR-NF-02, KR-BF-01, KR-BF-02

Offset Holder

Holder

Holder

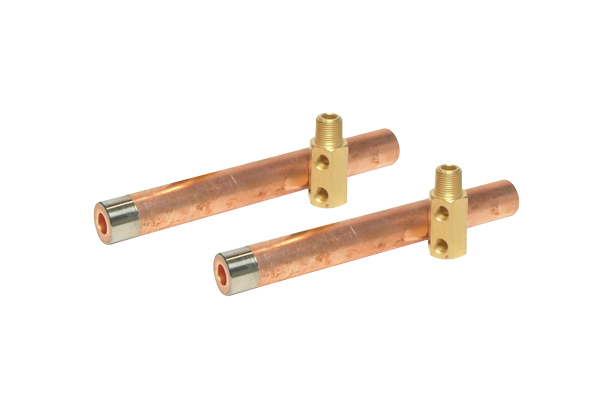

Co2 Welding Parts

Tip Remover

Jumper Cable

Sub Cable

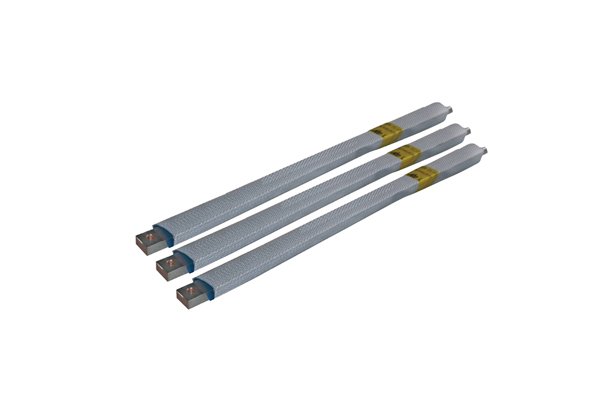

Kickless Cable

용접전류계SP-3510

용접전류계 (펄스통전 측정가능)SP-3288

디지털 가압력계SP-270

디지털 가압력계SP-255

유압식 가압력계SP-231

1/4