This product is manufactured by

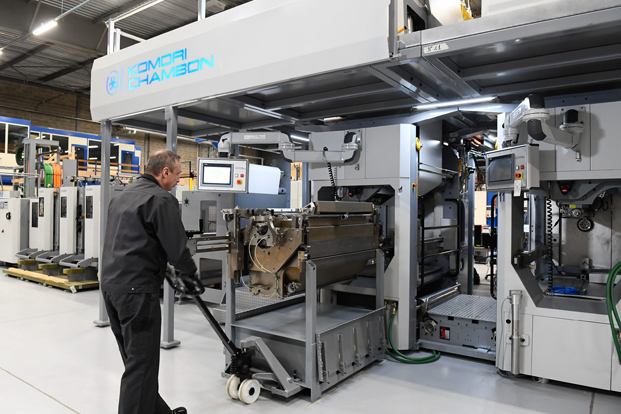

KOMORI CHAMBON

Manufacturer information

KOMORI CHAMBON

Verified & Trusted Manufacturer

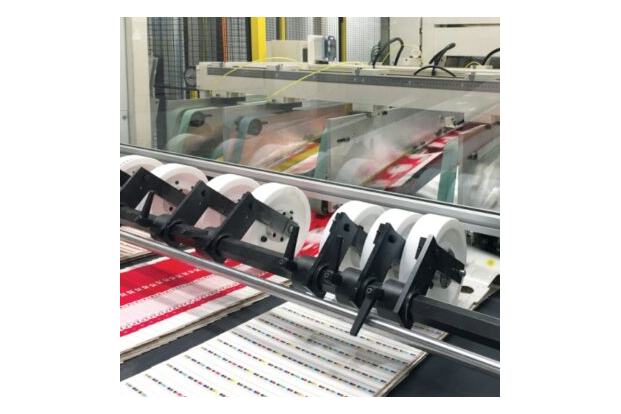

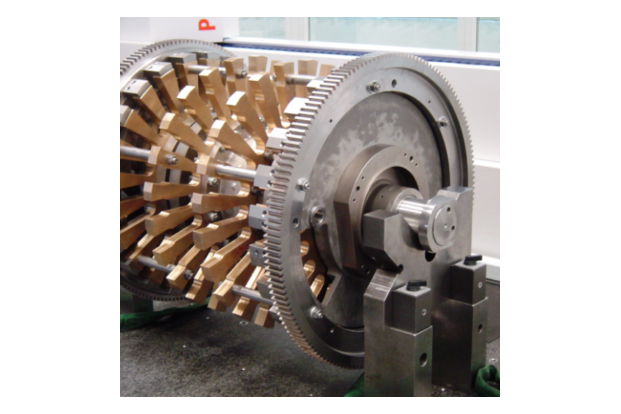

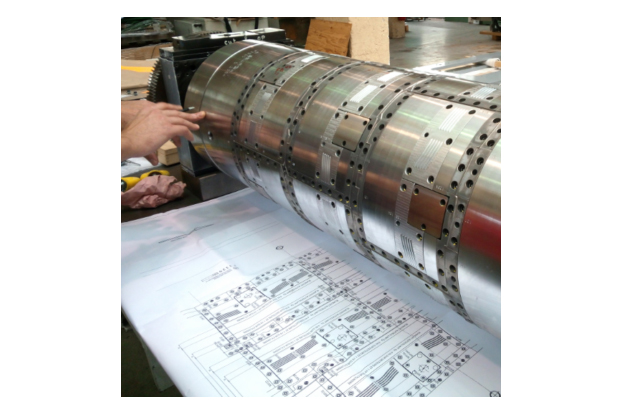

Printing Press Manufacturer, Printing, Converting, FLEXOGRAPHIC Solutions, ROTOGRAVURE Solutions and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

KOMORI CHAMBON

Product Type

Machine

Brand

-

SKU

137341

Product Name

DELIVERY solutions

Model Name

-

Size

-

Weight

-

Product Details