Overview

- Summary

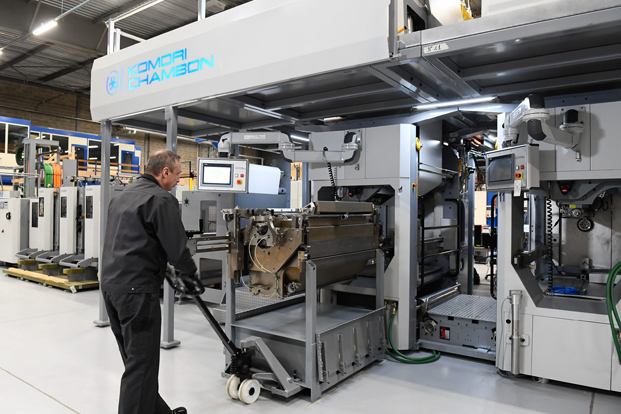

- Komori Chambon, a member of the Komori Group since 1989, is a specialized manufacturer of web-fed printing and converting solutions for premium-quality packaging. With over 130 years of history, the company is a global leader in web offset, rotogravure, and flexographic printing technologies, alongside rotary die-cutting and delivery solutions. It provides high-speed printing and precise converting machinery for the paperboard packaging market, offering customized, integrated solutions for diverse applications such as food, liquid, personal care, healthcare, and tobacco packaging. The company stands as a single-source supplier capable of providing end-to-end machinery that covers the entire printing and converting process.Komori Chambon, a member of the Komori Group since 1989, is a specialized manufacturer of web-fed printing and converting solutions for premium-quality packaging. With over 130 years of history, the company is a global leader in web offset, rotogravure, and flexographic printing technologies, alongside rotary die-cutting and delivery solutions. It provides high-speed printing and precise converting machinery for the paperboard packaging market, offering customized, integrated solutions for diverse applications such as food, liquid, personal care, healthcare, and tobacco packaging. The company stands as a single-source supplier capable of providing end-to-end machinery that covers the entire printing and converting process.

- Key Products/Technologies

- Web Offset Solutions: This product line integrates Komori's high-end offset automation into high-speed inline web-fed presses. It boasts a maximum printing width of up to 1220 mm (48 inches) and production speeds of 375 m/min (1230 ft/min), ensuring excellent color matching and image precision. Both cassette-type and sleeve-type technologies offer flexibility for various repeat lengths and quick job changeovers.Web Offset Solutions: This product line integrates Komori's high-end offset automation into high-speed inline web-fed presses. It boasts a maximum printing width of up to 1220 mm (48 inches) and production speeds of 375 m/min (1230 ft/min), ensuring excellent color matching and image precision. Both cassette-type and sleeve-type technologies offer flexibility for various repeat lengths and quick job changeovers.

- Rotogravure Solutions: Komori Chambon's rotogravure presses are built upon over 130 years of experience, enhanced by the latest technologies. These systems achieve a maximum speed of 500 m/min (roll-to-roll) with high color consistency, printing quality, and stability. Features include metallic ink control, automated and recordable settings, and low maintenance, contributing to maximum Overall Equipment Effectiveness (OEE).Rotogravure Solutions: Komori Chambon's rotogravure presses are built upon over 130 years of experience, enhanced by the latest technologies. These systems achieve a maximum speed of 500 m/min (roll-to-roll) with high color consistency, printing quality, and stability. Features include metallic ink control, automated and recordable settings, and low maintenance, contributing to maximum Overall Equipment Effectiveness (OEE).

- Flexographic Solutions: These flexographic units are designed for printing and coating applications, offering vertical or horizontal web path configurations with air or UV dryers. Their hybrid configuration allows integration as auxiliary units on offset or rotogravure lines, providing great versatility. Independent servomotor-driven shafts and sleeve-type cylinders ensure precise, safe operations and fast make-ready times.Flexographic Solutions: These flexographic units are designed for printing and coating applications, offering vertical or horizontal web path configurations with air or UV dryers. Their hybrid configuration allows integration as auxiliary units on offset or rotogravure lines, providing great versatility. Independent servomotor-driven shafts and sleeve-type cylinders ensure precise, safe operations and fast make-ready times.

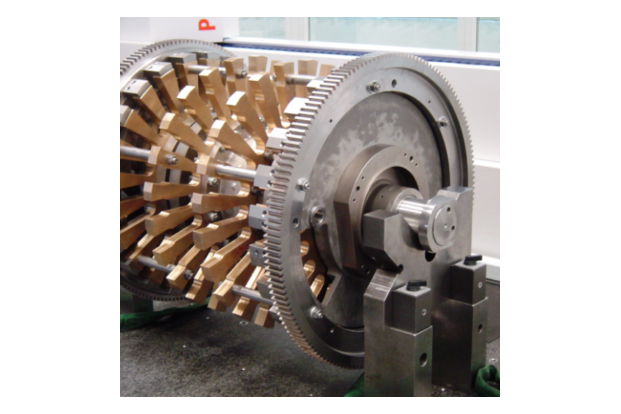

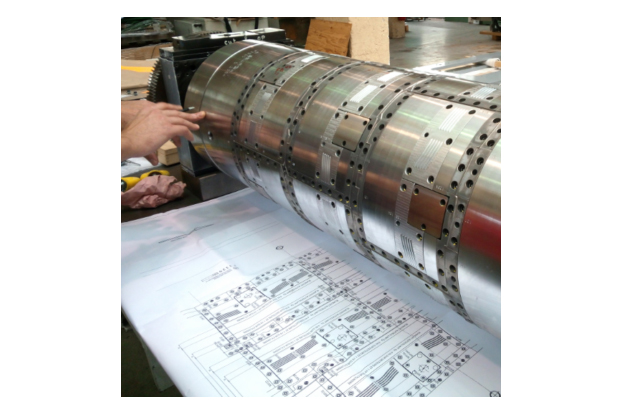

- Rotary Die-Cutting Solutions: The company offers rotary die-cutting systems that prioritize both quality and speed, regardless of cardboard characteristics. Its unique expertise lies in designing and manufacturing its own benches, cassettes, and tools for optimal control and ease of use. These systems achieve production speeds of up to 450 m/min (1480 ft/min) and deliver precise die-cutting without nick points.Rotary Die-Cutting Solutions: The company offers rotary die-cutting systems that prioritize both quality and speed, regardless of cardboard characteristics. Its unique expertise lies in designing and manufacturing its own benches, cassettes, and tools for optimal control and ease of use. These systems achieve production speeds of up to 450 m/min (1480 ft/min) and deliver precise die-cutting without nick points.

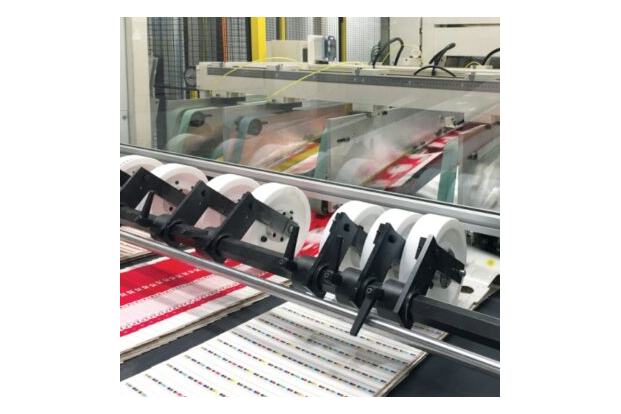

- Delivery Solutions: These systems manage blanks at high speeds, accommodating various layouts, dimensions, and cardboard specifications. Komori Chambon designs and manufactures tailor-made solutions for transfer, spreader, shingling, and stacking processes. With production speeds up to 450 m/min (1480 ft/min) and an optional diverter coupled with an optical inspection device, they ensure 100% good blanks.Delivery Solutions: These systems manage blanks at high speeds, accommodating various layouts, dimensions, and cardboard specifications. Komori Chambon designs and manufactures tailor-made solutions for transfer, spreader, shingling, and stacking processes. With production speeds up to 450 m/min (1480 ft/min) and an optional diverter coupled with an optical inspection device, they ensure 100% good blanks.

- Hybrid Printing Solutions: This offering combines all major printing processes—Offset, Flexo, Rotogravure—and can integrate digital solutions for variable printing, as well as added-value options like hot or cold foil. The core strength lies in its ability to perfectly synchronize all steps of the production flow and maintain full web tension control. These solutions are ideal for demanding designs involving complex color patches, highly detailed images, precise texts, and the use of recycled board.Hybrid Printing Solutions: This offering combines all major printing processes—Offset, Flexo, Rotogravure—and can integrate digital solutions for variable printing, as well as added-value options like hot or cold foil. The core strength lies in its ability to perfectly synchronize all steps of the production flow and maintain full web tension control. These solutions are ideal for demanding designs involving complex color patches, highly detailed images, precise texts, and the use of recycled board.

- Core Advantages

- End-to-End Solution Provider: The company is the sole manufacturer offering printing (Offset, Rotogravure, Flexography), converting (inline or offline), and rotary die tooling solutions from a single source. This capability ensures 100% process control and optimized production flows for customers.End-to-End Solution Provider: The company is the sole manufacturer offering printing (Offset, Rotogravure, Flexography), converting (inline or offline), and rotary die tooling solutions from a single source. This capability ensures 100% process control and optimized production flows for customers.

- Customized and Integrated Solutions Expertise: A core strength is the ability to deliver customized solutions that precisely match each customer's specific production needs. The company designs presses to address challenges such as achieving optimal print quality, improving cost efficiency, and meeting tight delivery schedules.Customized and Integrated Solutions Expertise: A core strength is the ability to deliver customized solutions that precisely match each customer's specific production needs. The company designs presses to address challenges such as achieving optimal print quality, improving cost efficiency, and meeting tight delivery schedules.

- High-Speed and Precision Technology: The company's equipment offers industry-leading production speeds, including 375 m/min for web offset presses, 450 m/min for rotary die-cutting and delivery solutions, and 500 m/min for rotogravure presses. Superior web tension control and automated settings ensure high precision and minimal waste.High-Speed and Precision Technology: The company's equipment offers industry-leading production speeds, including 375 m/min for web offset presses, 450 m/min for rotary die-cutting and delivery solutions, and 500 m/min for rotogravure presses. Superior web tension control and automated settings ensure high precision and minimal waste.

- Continuous Innovation and Expansion: As a Komori Group company, it has been a leader in web-fed packaging technology since 1989. Recent acquisitions of Bernal (rotary die-cutting) and Komori Primoflex Systems (KPS, flexographic printing) have further expanded its technological portfolio and strengthened its presence in the North American market.Continuous Innovation and Expansion: As a Komori Group company, it has been a leader in web-fed packaging technology since 1989. Recent acquisitions of Bernal (rotary die-cutting) and Komori Primoflex Systems (KPS, flexographic printing) have further expanded its technological portfolio and strengthened its presence in the North American market.

- Comprehensive Long-Term Customer Support: The company provides extensive, long-term premium services covering commissioning, reconditioning, and even relocation of production lines. Remote technical assistance, upgrades, audits, and training programs help customers maintain peak production line performance.Comprehensive Long-Term Customer Support: The company provides extensive, long-term premium services covering commissioning, reconditioning, and even relocation of production lines. Remote technical assistance, upgrades, audits, and training programs help customers maintain peak production line performance.

- Eco-Friendly and Automated Technologies: Integration of paper waste reduction technologies like KHS-AI enhances productivity and environmental responsiveness. Automated settings and flying changeovers reduce start-up waste and improve energy efficiency.Eco-Friendly and Automated Technologies: Integration of paper waste reduction technologies like KHS-AI enhances productivity and environmental responsiveness. Automated settings and flying changeovers reduce start-up waste and improve energy efficiency.

- Target Industrie

- Liquid PackagingLiquid Packaging

- General Folding CartonGeneral Folding Carton

- Tobacco PackagingTobacco Packaging

- Pharmaceuticals / Healthcare PackagingPharmaceuticals / Healthcare Packaging

- Luxury PackagingLuxury Packaging

- Security PrintingSecurity Printing

- Beverage CarriersBeverage Carriers

- Coating, Reverse PrintingCoating, Reverse Printing

- Sugar MouldingSugar Moulding

- Major Markets

- Japan (Komori Group headquarters), India (banknote printing lines supplied), China (manufacturing facility and market expansion efforts)Japan (Komori Group headquarters), India (banknote printing lines supplied), China (manufacturing facility and market expansion efforts)

- France (headquarters and plant), Italy (Komori Italia S.R.L established), United Kingdom (Komori U.K. Limited), Netherlands (Komori International Europe), Germany (MBO subsidiary)France (headquarters and plant), Italy (Komori Italia S.R.L established), United Kingdom (Komori U.K. Limited), Netherlands (Komori International Europe), Germany (MBO subsidiary)

- USA (Bernal acquisition, Rochester Hills), Canada (Komori Primoflex Systems (KPS) acquisition, Cambridge)USA (Bernal acquisition, Rochester Hills), Canada (Komori Primoflex Systems (KPS) acquisition, Cambridge)

- Certifications/Patents

- Enhancement of productivity and environmental responsiveness through paper waste reduction technologies like KHS-AI.Enhancement of productivity and environmental responsiveness through paper waste reduction technologies like KHS-AI.

- Integration of Komori's high-end offset automation technology into web offset presses.Integration of Komori's high-end offset automation technology into web offset presses.

- Incorporation of cutting-edge technologies such as independent unit drive, remote control automatic plate register adjustment, automatic ink roller cleaning, zero-setting function, and PQC (Print Quality Controller).Incorporation of cutting-edge technologies such as independent unit drive, remote control automatic plate register adjustment, automatic ink roller cleaning, zero-setting function, and PQC (Print Quality Controller).

- Proprietary technology for designing and manufacturing benches, cassettes, and tools for rotary die-cutting systems.Proprietary technology for designing and manufacturing benches, cassettes, and tools for rotary die-cutting systems.

- Patented roller system for high-speed delivery, ensuring proper carton knockdown and eliminating high-speed jam-ups.Patented roller system for high-speed delivery, ensuring proper carton knockdown and eliminating high-speed jam-ups.

- Patented solid shafts combined with lightweight aluminum sleeves to prevent slipping and bouncing during printing operations.Patented solid shafts combined with lightweight aluminum sleeves to prevent slipping and bouncing during printing operations.

Introduction

Key Products

Location

11 Av. Buffon, 45100 Orléans, France

클릭하여 위치 살펴보기