Overview

- Summary

- INT KOREA is a specialized manufacturer of flexible packaging machinery, focusing on the production and sale of high-performance gravure printing machines, laminating machines, coating machines, winders, and slitters. The company possesses innovative technology and over 20 years of extensive experience, serving as a global enterprise that meets diverse customer demands both domestically and internationally.INT KOREA is a specialized manufacturer of flexible packaging machinery, focusing on the production and sale of high-performance gravure printing machines, laminating machines, coating machines, winders, and slitters. The company possesses innovative technology and over 20 years of extensive experience, serving as a global enterprise that meets diverse customer demands both domestically and internationally.

- Key Products/Technologies

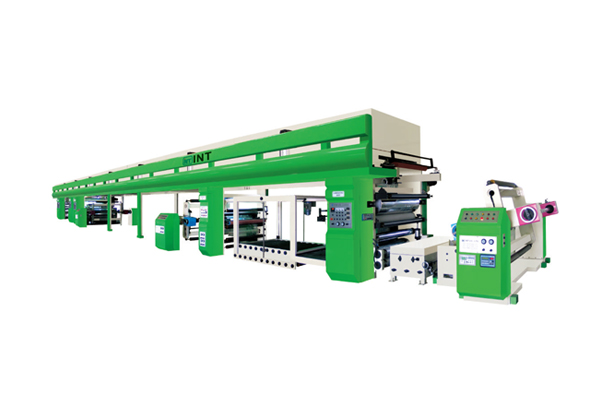

- Rotogravure Printing Machines, including ILC-PR Series and ILC-PR-SE Series models. The ILC-PR-SE Series is a high-performance printing equipment based on a sectional drive system, supporting machine speeds of up to 350m/min and web widths of 600-1,500mm. This model offers optimal efficiency and economy for the flexible packaging industry, ensuring excellent print quality for both short and long production runs.Rotogravure Printing Machines, including ILC-PR Series and ILC-PR-SE Series models. The ILC-PR-SE Series is a high-performance printing equipment based on a sectional drive system, supporting machine speeds of up to 350m/min and web widths of 600-1,500mm. This model offers optimal efficiency and economy for the flexible packaging industry, ensuring excellent print quality for both short and long production runs.

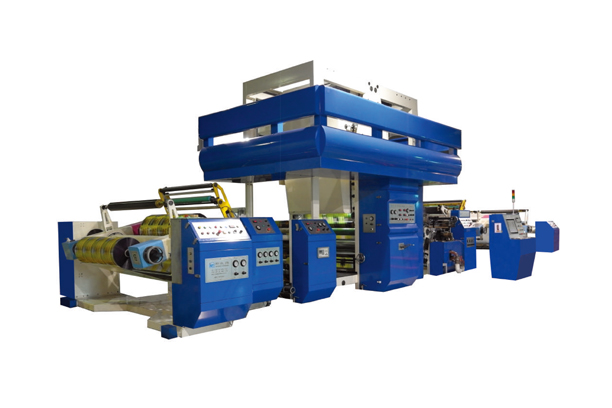

- Dry Laminating Machines, specifically the ILC-DL Series model. This solvent-based dry lamination equipment features machine speeds of up to 300m/min and web widths of 600-1,500mm. It incorporates an advanced Web Tension Control System, enabling the processing of various material combinations such as plastic films, aluminum foil, and paper.Dry Laminating Machines, specifically the ILC-DL Series model. This solvent-based dry lamination equipment features machine speeds of up to 300m/min and web widths of 600-1,500mm. It incorporates an advanced Web Tension Control System, enabling the processing of various material combinations such as plastic films, aluminum foil, and paper.

- Extrusion Laminating Machines, including ILC-EL Series, ILC-EL-CO Series, and ILC-TEL Series models. These machines apply extrusion laminating technology to a wide range of web materials, including plastic films, BOPP, OPP, PET, PE, paper, and aluminum foil. Their flexible design allows for adjustable web and guide roll widths based on customer requirements.Extrusion Laminating Machines, including ILC-EL Series, ILC-EL-CO Series, and ILC-TEL Series models. These machines apply extrusion laminating technology to a wide range of web materials, including plastic films, BOPP, OPP, PET, PE, paper, and aluminum foil. Their flexible design allows for adjustable web and guide roll widths based on customer requirements.

- Coating Machines, such as the ILC-CO Series model. These coating units utilize micro and comma coating methods, applicable to PET films, plastic films, paper, and aluminum foil. They support web widths of up to 1,600mm, providing versatile coating solutions for various industrial needs.Coating Machines, such as the ILC-CO Series model. These coating units utilize micro and comma coating methods, applicable to PET films, plastic films, paper, and aluminum foil. They support web widths of up to 1,600mm, providing versatile coating solutions for various industrial needs.

- Slitting Machines, including the ILC-TSR Series model. These machines offer precise slitting and rewinding capabilities with a maximum web width of 1700mm and a machine speed of 120m/min. Their unique design minimizes high edge silver, ensuring superior winding quality control through high-precision concentric chuck friction winding shafts.Slitting Machines, including the ILC-TSR Series model. These machines offer precise slitting and rewinding capabilities with a maximum web width of 1700mm and a machine speed of 120m/min. Their unique design minimizes high edge silver, ensuring superior winding quality control through high-precision concentric chuck friction winding shafts.

- A diverse lineup of flexible packaging machinery, including Solventless Laminating Machines (ILC-NSL Series) and Wet Laminating Machines (ILC-WL Series). These products aim to enhance customer productivity and reduce operational costs with optimized solutions.A diverse lineup of flexible packaging machinery, including Solventless Laminating Machines (ILC-NSL Series) and Wet Laminating Machines (ILC-WL Series). These products aim to enhance customer productivity and reduce operational costs with optimized solutions.

- Core Advantages

- Over 20 years of extensive experience and unique know-how in specialized flexible packaging machinery manufacturing. This expertise forms the foundation for producing high-quality machines that meet customer satisfaction.Over 20 years of extensive experience and unique know-how in specialized flexible packaging machinery manufacturing. This expertise forms the foundation for producing high-quality machines that meet customer satisfaction.

- The ability to provide customized solutions that meet specific customer requirements and maximize both quality and cost-efficiency. Optimized machine designs for increased customer production and actual cost savings.The ability to provide customized solutions that meet specific customer requirements and maximize both quality and cost-efficiency. Optimized machine designs for increased customer production and actual cost savings.

- Highly efficient and economical machine designs optimized for the flexible packaging industry. These models ensure excellent quality for short, medium, and long production runs.Highly efficient and economical machine designs optimized for the flexible packaging industry. These models ensure excellent quality for short, medium, and long production runs.

- An advanced Web Tension Control System for processing a wide range of web materials and maintaining extremely low tolerance for various flexible substrates. This capability allows for stable lamination of diverse material combinations, including plastic films, aluminum foil, and paper.An advanced Web Tension Control System for processing a wide range of web materials and maintaining extremely low tolerance for various flexible substrates. This capability allows for stable lamination of diverse material combinations, including plastic films, aluminum foil, and paper.

- Strong global competitiveness through active exports to international markets, including Turkey, Malaysia, Indonesia, Vietnam, Thailand, Japan, China, India, Bangladesh, and Australia. A track record of supplying over 100 lines worldwide.Strong global competitiveness through active exports to international markets, including Turkey, Malaysia, Indonesia, Vietnam, Thailand, Japan, China, India, Bangladesh, and Australia. A track record of supplying over 100 lines worldwide.

- A firm commitment to manufacturing the best quality printing, coating, and laminating machines at the most competitive prices. Continuous efforts to maintain price competitiveness without compromising quality.A firm commitment to manufacturing the best quality printing, coating, and laminating machines at the most competitive prices. Continuous efforts to maintain price competitiveness without compromising quality.

- Target Industrie

- Packaging IndustryPackaging Industry

- Printing IndustryPrinting Industry

- Coating IndustryCoating Industry

- Flexible Packaging IndustryFlexible Packaging Industry

- Major Markets

- Malaysia, Indonesia, Vietnam, Thailand, Japan, China, India, BangladeshMalaysia, Indonesia, Vietnam, Thailand, Japan, China, India, Bangladesh

- TurkeyTurkey

- AustraliaAustralia

- Certifications/Patents

- Possession of advanced manufacturing technology for high-performance flexible packaging machinery, backed by over 20 years of experience and know-how. This represents a continuous effort in technological development aimed at customer satisfaction.Possession of advanced manufacturing technology for high-performance flexible packaging machinery, backed by over 20 years of experience and know-how. This represents a continuous effort in technological development aimed at customer satisfaction.

- Gravure printing machine technology incorporating an advanced sectional drive system. A strong mechanical structure that maximizes machine performance at peak operating speeds.Gravure printing machine technology incorporating an advanced sectional drive system. A strong mechanical structure that maximizes machine performance at peak operating speeds.

- Sophisticated web tension control system technology for stable processing of various web materials. The capability to maintain extremely low tolerances across a wide range of flexible substrates.Sophisticated web tension control system technology for stable processing of various web materials. The capability to maintain extremely low tolerances across a wide range of flexible substrates.

- Application of diverse coating technologies, including micro and comma coating methods. Provision of coating solutions for various materials such as PET films, plastic films, paper, and aluminum foil.Application of diverse coating technologies, including micro and comma coating methods. Provision of coating solutions for various materials such as PET films, plastic films, paper, and aluminum foil.

Introduction

Key Products

Location

59 Cheongwonsandan 3-gil, Mado-myeon, Hwaseong-si, Gyeonggi-do, South Korea

클릭하여 위치 살펴보기