This product is manufactured by

CLEANTEC

Manufacturer information

CLEANTEC

Centrifugal separator manufacturer, Filter device, Cleaning machine, Honning machine, Wrapping machine and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

CLEANTEC

Product Type

Machine

Brand

-

SKU

4793

Product Name

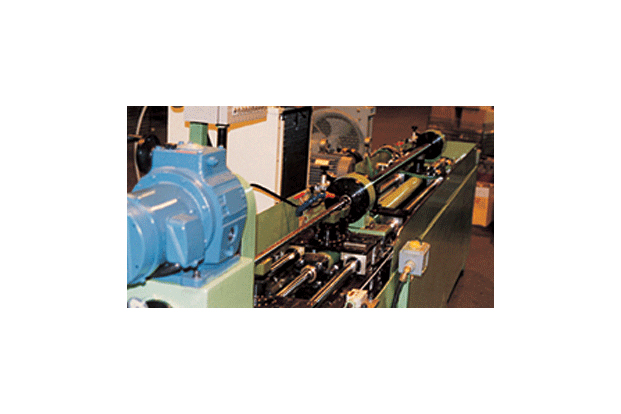

Power Automatic Models

Model Name

PSF-100A, PSF- 200A, PSF-400A

Size

-

Weight

-

Product Details

More products

Hydrauric Expansion Type Verical Honing MachineVH-01S, VH-02S, VH-03S, VH-04S, VH-06S, VH-08S, VH-10S, VH-12S, VH-15S, VH-20S, VH-25S, VH-30S, VH-01D, VH-01D, VH-02D, VH-03D, VH-04D, VH-06D, VH-08D, VH-10D, VH-12D, VH-15D, VH-20D, VH-25D, VH-30D

Automatic ModelsSF-50A, SF-100A, SF-200A

Spherical Honing Machine

Lapping MachineCLM-10S, CLM-10D

Horizontal Honing MachineHM20, HM40, HM60, HM80, HM120

Disc Honing MachineDH-H, DH-V

CNC Vertical Honing MachineCVH-03S, CVH-06S, CVH-12S, CVH-03D, CVH-06D, CVH-12D

Manual ModelsSF-50N, SF-100N

One Pass Honing Machine (Multi Spindle)SP10, SP15, SP20, SP30

Semi-AutomaticSF-50S, SF-100S, SF-200S

Liquid / Solid SeparatorsSF-100A, SF-200A

1/3