지금 보고 계신 제품의 제조사에요

융하인리히

이 기업의 다른 제품

Automated stackerERC 213a, ERC 217a

LPG forklift truckFTG 18, FTG 25, FTG 30

Diesel forklift truckFTD 18, FTD 25, FTD 30

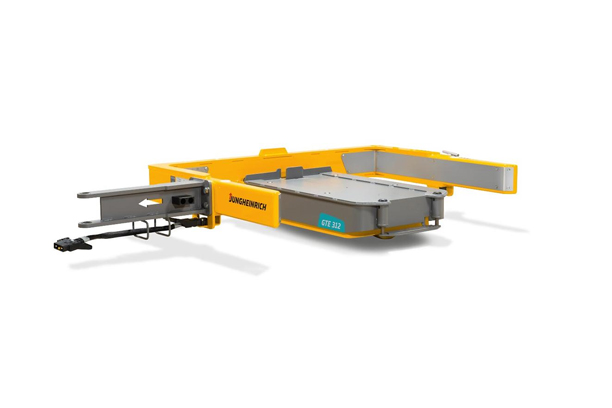

Robust E-frame trailer 0.6 - 1.2tGTE 106, GTE 212, GTE 312

Tow tractor 7.0 - 10.0tEZS 570, EZS 580, EZS 590, EZS 5100

Electric four-wheel counterbalance forklift truck 1.6t-3tEFG BC 316, EFG BC 320, EFG BC 325k, EFG BC 325, EFG BC 330

Reach truck 1.8 - 2.5tETV 318, ETV 320, ETV 325, ETM 325

Medium/high level order picker 1.0 - 1.2tEKS 310, EKS 412

Order picker 2.0 - 2.5tECE 220, ECE 225, ECE 227 (AU)

Pedestrian pallet truck 2.2 - 3.5tEJE 222, EJE 225, EJE 230, EJE 235

Pedestrian pallet truck 2.2 - 2.5tEJE 222r, EJE 225r

Electric pedestrian pallet truck 1600 / 2000 kgEJE 116n, EJE 120n

Tow tractor 28.0tEZS 7280

Automatic tow tractorEZS 350a

Automated Guided Vehicle System Self-Supported Stacker AGVEKS-215a

1/4