This product is manufactured by

YOUNGJIN WORM

NUT lifting Ball Screw Jack

Model Name

KOB

Manufacturer information

YOUNGJIN WORM

Precision Worm Reducer, Gantry Robot 3:1 Reducer, Dual Pitch Cavex Reducer, Dual Lead Worm, Screw Jack and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

YOUNGJIN WORM

Product Type

Machine

Brand

-

SKU

142182

Product Name

NUT lifting Ball Screw Jack

Model Name

KOB, K1B, K2B, K3B, K4B, K5B, K6B, K6 1/2B, K7B

Size

-

Weight

-

Product Details

More products

Ball Screw JackKOB, K1B, K2B, K3B, K4B, K5B, K6B, K6 1/2B, K7B

SCREW JACKKOC, K1C, K2C, K3C, K3 1/2C, K4A, K5A, K6A, K6 1/2A, K7A

Small JackKSC

Small Ball Screw JackKSB

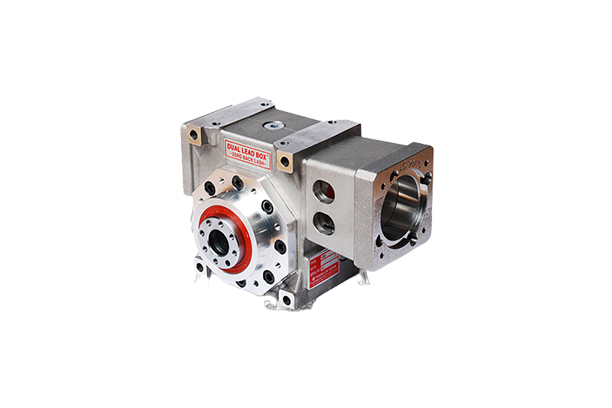

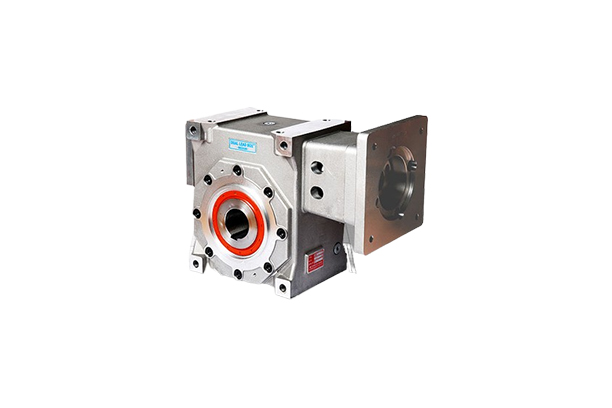

Dual Lead Worm

NC-ROTARY TABLE용 듀얼리드웜SET

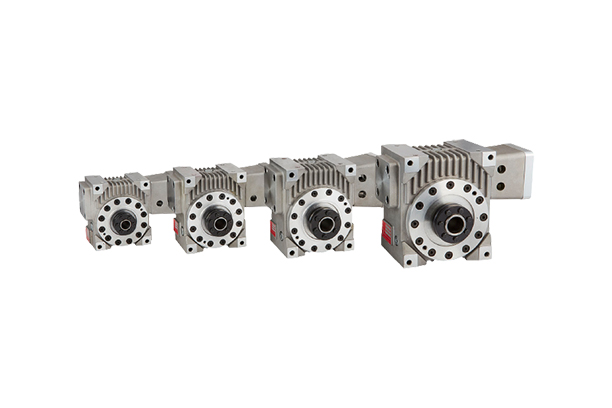

Gantry robot 3:1 reducer

Robot Flange

Dual output shaft

Single output shaft

Hollow Shaft Keyed

Hollow shaft-Shrink Disc

Hollow shaft-Shrink Disc

Dual Pitch Cavex Reducer

1/4