This product is manufactured by

UNI-RAM

Solvent Recycler

Model Name

URS900CE

Manufacturer information

UNI-RAM

Solvent Spray Gun Cleaners Manufacture, Water Spray Gun Cleaners and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

UNI-RAM

Product Type

Machine

Brand

-

SKU

139791

Product Name

Solvent Recycler

Model Name

URS900CE

Size

-

Weight

-

Product Details

More products

The Mobile VacuumUR300QVAC

Automatic Spray Gun CleanerUG2000DM

Continuous Industrial Solvent RecyclerDC100N

Pumping StationUPS40DA

Oil Filter and Can CrusherUFC850C

Portable Pumping StationUPS20DA

Pumping StationUPS10DA

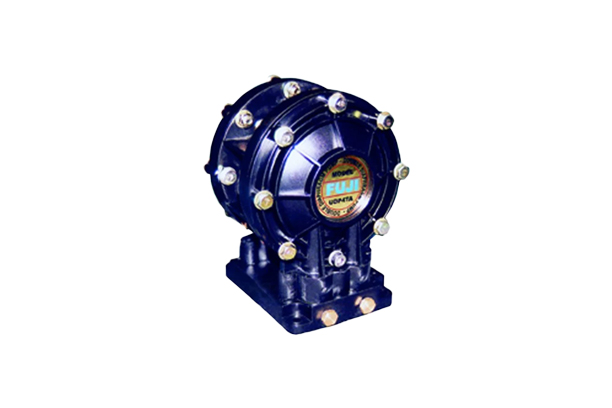

Diaphragm PumpUDP5TA

Diaphragm PumpUDP4TA

Diaphragm PumpUDP2TS

Pressure Sand BlasterU100

Part Washer With Solvent Recycler23NL

Pail CompactorUCC840C

Industrial Solvent RecyclerDB100CE

Industrial Solvent RecyclerBB30CE

Automotive Solvent RecyclerURS600CE

1/4