This product is manufactured by

NUMALLIANCE

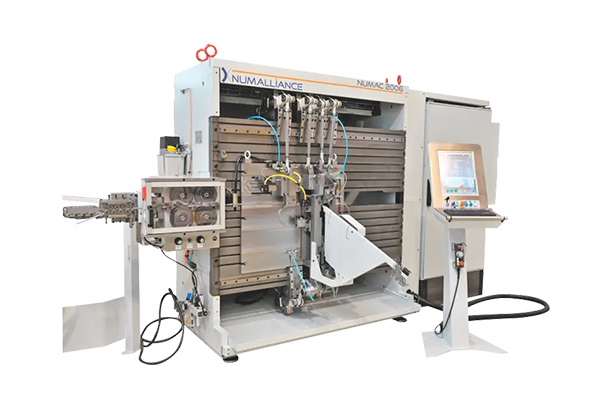

CNC Automatic Wire Bending Machine Numac Numaflex

Model Name

NUMAC 2006

Manufacturer information

NUMALLIANCE

Verified & Trusted Manufacturer

Providers of Turnkey Productivity Solutions for Cold Forming Metal Wire, Tube, and Flat-stock

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

NUMALLIANCE

Product Type

Machine

Brand

-

SKU

137076

Product Name

CNC Automatic Wire Bending Machine Numac Numaflex

Model Name

NUMAC 2006, NUMAC 2008, NUMAC 2010, NUMAC 3006, NUMAC 3008, NUMAC 3010

Size

-

Weight

-

Product Details

More products

CNC Spring Forming Machine FRXFRX04, FRX06

CNC Wire Bending Machine Robomac TFR106TF G4, R108TF G4, R206TF G4, R208TF G4, R210TF G4, R213TF G4, R214TF G4, R216TF G4, R310TF G4

CNC Bending Machine FTXFTX08 G4, FTX10 G4, FTX13 G4, FTX 13 G8, FTX 14 G8, FTX16 G8

CNC Wire Bending Machine Robomac 2 HeadsR2104TF, R2105TF, R2106TF, R2108TF, R2110TF, R2112TF

CNC Wire Cutting Machine NumacutNUMACUT W05, NUMACUT W08, NUMACUT W12

CNC Bending Machine FTXFTX08 G4, FTX10 G4, FTX13 G4, FTX 13 G8, FTX 14 G8, FTX16 G8

Robomac TFER213TF G4, R214TF G8, R216TF G8

Standard Hydraulic Pressh-P100, h-P200

CNC Bender NumabendT815

CNC Flat Stock Bender FPXFPX Series

CNC FPX BusbarFPX Busbar

CNC Automatic Wire Bender R4xxR4 Series

CNC Strip Bending Machine NumastripNumastrip

CNC Pipe Bending Machine NumatubeNumatube 80

Eaton Leonard VB SMALLVB 19 ELEC

Numacell FTR

1/4