Overview

- Summary

- Numalliance, established in 1986, is a leading provider of turnkey productivity solutions for cold forming metal wire, tube, and sheet metal. The company offers a diverse product range including CNC wire and tube bending machines, end forming machines, presses, and laser cutting solutions. It specializes in automated production systems that integrate secondary operations such as notching, cutting, and welding, along with Industry 4.0 technologies.Numalliance, established in 1986, is a leading provider of turnkey productivity solutions for cold forming metal wire, tube, and sheet metal. The company offers a diverse product range including CNC wire and tube bending machines, end forming machines, presses, and laser cutting solutions. It specializes in automated production systems that integrate secondary operations such as notching, cutting, and welding, along with Industry 4.0 technologies.

- Key Products/Technologies

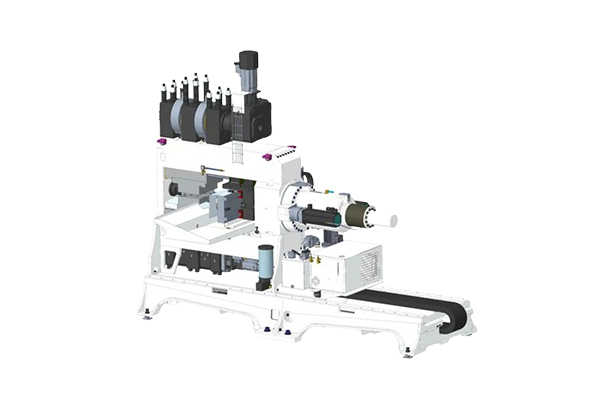

- Numalliance provides core product lines including CNC wire bending machines, tube bending machines, tube end forming machines, wire and tube cutting machines, and various press equipment. The CNC wire benders Robomac e-Motion (R106 e-Motion, R206 e-Motion, R210 e-Motion, R310 e-Motion) and Robomac TF (R106TF G4, R108TF G4, R206TF G4, R208TF G4, R210TF G4, R213TF G4, R214TF G4, R216TF G4, R310TF G4) offer precise 3D bending capabilities for wires ranging from 0.8mm to 16mm in diameter.Numalliance provides core product lines including CNC wire bending machines, tube bending machines, tube end forming machines, wire and tube cutting machines, and various press equipment. The CNC wire benders Robomac e-Motion (R106 e-Motion, R206 e-Motion, R210 e-Motion, R310 e-Motion) and Robomac TF (R106TF G4, R108TF G4, R206TF G4, R208TF G4, R210TF G4, R213TF G4, R214TF G4, R216TF G4, R310TF G4) offer precise 3D bending capabilities for wires ranging from 0.8mm to 16mm in diameter.

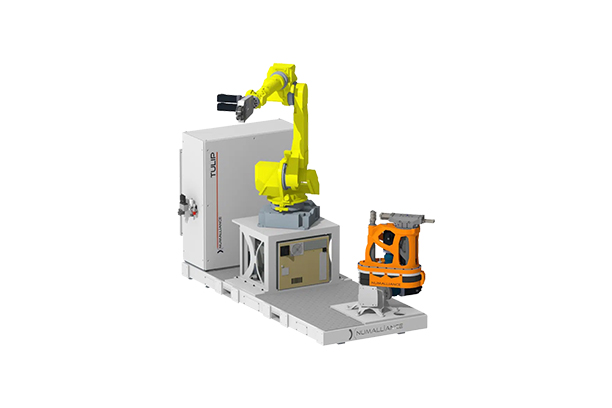

- The Robomac TFE (R213TF G4, R214TF G8, R216TF G8) is a model suitable for complex part production through its 2-head bending technology. Robotic tube bending machines like Tulip 19 and Numaform 70 provide all-electric bending and end forming solutions for tubes with diameters from 4mm to 152mm.The Robomac TFE (R213TF G4, R214TF G8, R216TF G8) is a model suitable for complex part production through its 2-head bending technology. Robotic tube bending machines like Tulip 19 and Numaform 70 provide all-electric bending and end forming solutions for tubes with diameters from 4mm to 152mm.

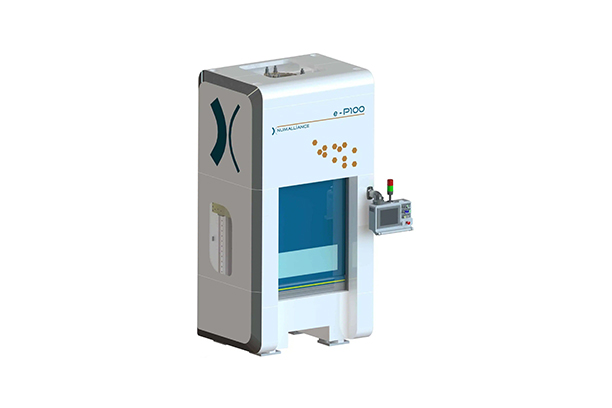

- Numaform utilizes 5/8/12/30 ton ram power for single or multi-hit end forming of materials ranging from 3mm to 250mm. The company also offers a variety of customized press equipment including Standard Hydraulic Presses (h-P100, h-P200), Electric Presses (e-P50, e-P100), Thermocompression Laboratory Presses (COHC15, COHC50, COHC100), and Stretch Bender Presses for Bumper Beams.Numaform utilizes 5/8/12/30 ton ram power for single or multi-hit end forming of materials ranging from 3mm to 250mm. The company also offers a variety of customized press equipment including Standard Hydraulic Presses (h-P100, h-P200), Electric Presses (e-P50, e-P100), Thermocompression Laboratory Presses (COHC15, COHC50, COHC100), and Stretch Bender Presses for Bumper Beams.

- The CTR-e is an all-electric cutting solution capable of cutting tubes from 40mm to 76x2mm in diameter without chips. Numalliance actively integrates Industry 4.0 and 5.0 technologies into its products, such as 3D control and auto-correction, robot integration, proprietary software development, and remote control capabilities.The CTR-e is an all-electric cutting solution capable of cutting tubes from 40mm to 76x2mm in diameter without chips. Numalliance actively integrates Industry 4.0 and 5.0 technologies into its products, such as 3D control and auto-correction, robot integration, proprietary software development, and remote control capabilities.

- Core Advantages

- A global leadership position as a provider of turnkey productivity solutions for cold forming metal wire, tube, and sheet metal.A global leadership position as a provider of turnkey productivity solutions for cold forming metal wire, tube, and sheet metal.

- Extensive technological expertise and the ability to integrate diverse secondary operations beyond bending, including notching, cutting, punching, chamfering, welding, threading, embossing, robotization, thermal stabilization, 3D control, and automatic program correction.Extensive technological expertise and the ability to integrate diverse secondary operations beyond bending, including notching, cutting, punching, chamfering, welding, threading, embossing, robotization, thermal stabilization, 3D control, and automatic program correction.

- A robust global production and sales network, with design and manufacturing facilities in France, the USA, and Mexico, supported by 11 subsidiaries and technical sales offices (USA, Mexico, China, India, Russia, Slovakia, Germany, Brazil, Romania) and a network of 40 agents worldwide.A robust global production and sales network, with design and manufacturing facilities in France, the USA, and Mexico, supported by 11 subsidiaries and technical sales offices (USA, Mexico, China, India, Russia, Slovakia, Germany, Brazil, Romania) and a network of 40 agents worldwide.

- Continuous innovation and significant R&D investment, with one-third of its workforce dedicated to engineering and R&D, leading to the integration of Industry 4.0 and 5.0 technologies, proprietary software development, and patented technologies such as the "bend die with integrated wiper die".Continuous innovation and significant R&D investment, with one-third of its workforce dedicated to engineering and R&D, leading to the integration of Industry 4.0 and 5.0 technologies, proprietary software development, and patented technologies such as the "bend die with integrated wiper die".

- Flexibility in providing customized solutions, designing and manufacturing standard and tailor-made machines and work cells to meet specific customer requirements, and a worldwide reputation for product quality, accuracy, productivity, and flexibility.Flexibility in providing customized solutions, designing and manufacturing standard and tailor-made machines and work cells to meet specific customer requirements, and a worldwide reputation for product quality, accuracy, productivity, and flexibility.

- Commitment to sustainable solutions through low energy consumption with all-electric machines, scrap reduction, and retrofitting existing equipment.Commitment to sustainable solutions through low energy consumption with all-electric machines, scrap reduction, and retrofitting existing equipment.

- Target Industrie

- Automotive industry (seat structures, exhaust systems, fluid transport, E-mobility, stator and bus bar production).Automotive industry (seat structures, exhaust systems, fluid transport, E-mobility, stator and bus bar production).

- Aeronautics industry.Aeronautics industry.

- Agriculture sector.Agriculture sector.

- Construction and HVAC (Heating, Ventilation, Air Conditioning) sectors.Construction and HVAC (Heating, Ventilation, Air Conditioning) sectors.

- Sanitary and furniture industries.Sanitary and furniture industries.

- Medical device field.Medical device field.

- Shop equipment and retail industries.Shop equipment and retail industries.

- Luxury goods and home appliance manufacturing sectors.Luxury goods and home appliance manufacturing sectors.

- Major Markets

- China, India, VietnamChina, India, Vietnam

- France (headquarters and production sites), Germany, Slovakia, Romania, Russia, United KingdomFrance (headquarters and production sites), Germany, Slovakia, Romania, Russia, United Kingdom

- USA, MexicoUSA, Mexico

- BrazilBrazil

- Certifications/Patents

- Patent for a shaping station of a wire shaping machine with an annular tool holder arm (US Patent No.: 8756968).Patent for a shaping station of a wire shaping machine with an annular tool holder arm (US Patent No.: 8756968).

- Patent for a machine for cambering, forming, folding or bending bars, wires or extruded shapes (US Patent No.: 8220304).Patent for a machine for cambering, forming, folding or bending bars, wires or extruded shapes (US Patent No.: 8220304).

- Patent for a bending machine for rods with a resettable folding shank (US Patent No.: 6813922).Patent for a bending machine for rods with a resettable folding shank (US Patent No.: 6813922).

- Patent for a wire supply station (US Patent No.: 8783084).Patent for a wire supply station (US Patent No.: 8783084).

- Innovative patented technologies such as the "bend die with integrated wiper die".Innovative patented technologies such as the "bend die with integrated wiper die".

- Qualiopi certification, ensuring the quality and reliability of its training programs.Qualiopi certification, ensuring the quality and reliability of its training programs.

- Industrial recognition as a member of "Réseau Entreprendre LORRAINE" and "Bpi france Excellence," and a company labeled "Ambassadeurs des Vosges".Industrial recognition as a member of "Réseau Entreprendre LORRAINE" and "Bpi france Excellence," and a company labeled "Ambassadeurs des Vosges".

- Contribution to European industrial development through support from the French government's "France Relance" program.Contribution to European industrial development through support from the French government's "France Relance" program.

Introduction

Key Products

Location

Parc d'Activités, 88470 Saint-Michel-sur-Meurthe, France

클릭하여 위치 살펴보기