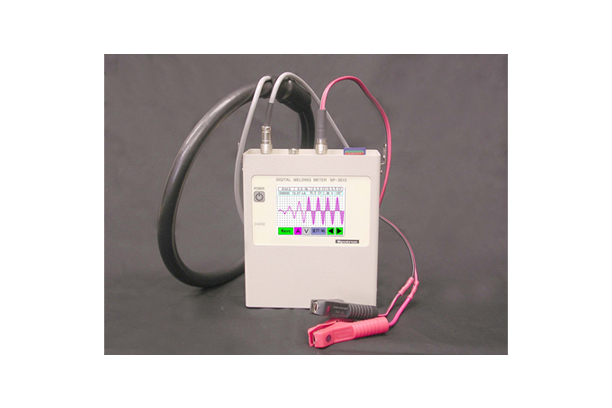

This product is manufactured by

KMJ

Nut & Bolt Manager

Model Name

KBM-001

Manufacturer information

KMJ

Resistance welding machine, Cable for welding, Special alloy, Electric control device, Arc parts, Welding apparatus

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

KMJ

Product Type

Machine

Brand

-

SKU

142158

Product Name

Nut & Bolt Manager

Model Name

KBM-001, KBM-002

Size

-

Weight

-

Product Details