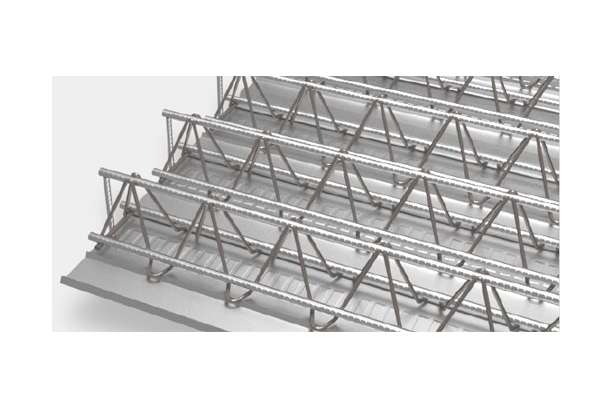

Superdeck is

a product using a “Non-cast and Non-Retaining-Wall Slab construction” method which contains Truss Girder assembled with Deformed Wires of high-yield strength and galvanized steel plate instead of wooden cast. The electric resistance welding has been used to integrate those two as well as the final products come off the automatic assembly line. Quick and easy installation is the well-known competitiveness of Superdeck (superdeck) which can be completed as an alternative of installation of cast or arrangement of rebar. It is a method which allows following process to be done without cast disassembling( disassembling cast).

1. High Quality

Stable structural system using Truss Joist

Arrangement of slab with high accuracy & high strength

Application of Camber considering displacement by construction load

Identical and high-quality product by factory production

Maintenance of the thickness of Sheath and Spacing of Rebar

2. Cost Down

Transport of small quantity by worker due to lightness

Reduction of Shore installation costs

No-need of Spacers for arrangement of rebar

Decrease of industrial waste

3. Safety

Safe construction even by unskilled workers

Low weight in favor of safe construction

Easy for safe management : Reduction of field operations, simple & repetitive tasks

4. Time Saving

Reduced field operations by order production at factory using design drawings

No need of cast disassembling ( disassembling cast)→ Early starting of following processes

Easy to organize the working environment

5. Planning

Widely applicable with S/RC/SRC

Applicable for various floor types (commercial building, office, hotel, school, hospital, factory and etc.)

Applicable to Slab thickness of 120 ~ 300 mm