지금 보고 계신 제품의 제조사에요

K-SYSTEMS-TOBOL

구매정보

K-SYSTEMS-TOBOL

정보 인증을 완료한 신뢰할 수 있는 기업입니다.

Diamond burnishing tools and roller burnishing tools Manufacturer, Sensor Tool

연락처

+7 906 884-60-97

이메일

310182@inbox.ru

상품정보에 문제가 있나요?

정보수정 / 삭제요청

코머신은 제품 판매자가 아닙니다.법적고지 및 안내

제조사

K-SYSTEMS-TOBOL[바로가기]

제품 타입

기계

브랜드

-

SKU

135565

제품명

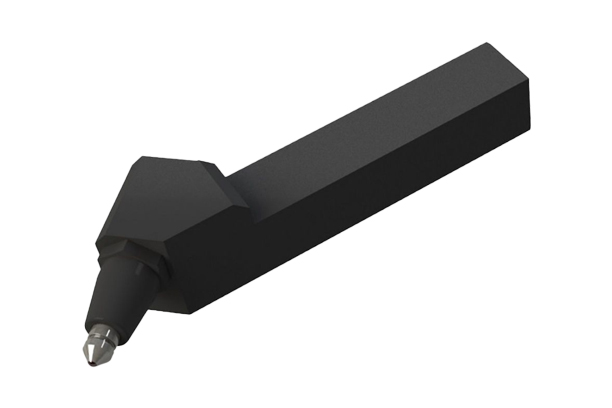

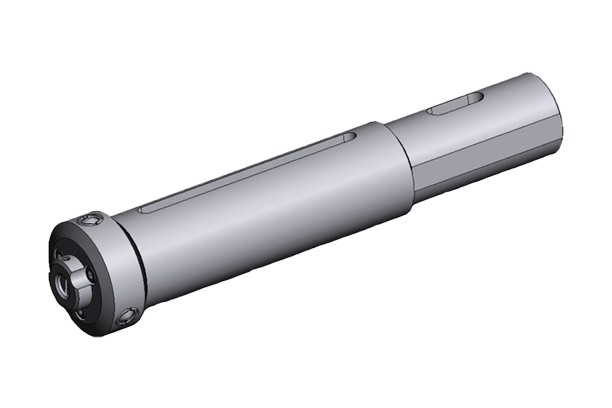

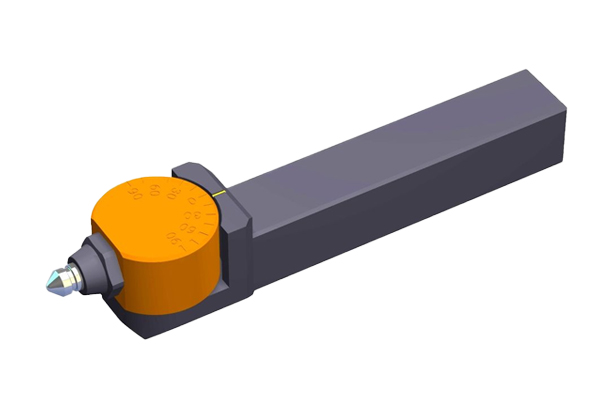

Burnishing Tool for Radius, Angle and Steplike Surfaces

모델명

ST7-25L, ST7-25R

사이즈

-

중량

-

제품 상세 정보

이 기업의 다른 제품

Single-Roller Burnishing Tool for Angle Surface SuperfinishingSTR3-02, STR3-02R, STR3-02L

Single-Roller Burnishing Tool for External Surface Superfinishing ProcessingSTR3-01, STR3-01R, STR3-01L

Diamond Burnishing Tool for Plain Surfaces Burnishing MillST-11, ST11-47

Cutting Tool for Hard Turning with CoolingST-22

Combined Skiving and Roller Burnishing Tool 2 in 1STGA-T

Roller Burnishing Tool for Large HolesSTR8-180

Diamond Burnishing Tool for Hydraulic Cylinder LinersST-12

Roller Burnishing Tool for HolesSTR-8

Single-Roller Universal Rolling Burnishing Tool for Machining External Surfaces, Faces and HolesSTR-5

Ball Burnishing and Surface Hardening Tool for HolesSTR-2

Ball Burnishing and Surface Hardening ToolSTR-1

Universal Rotatable Diamond Burnishing ToolST-21

Diamond Burnishing Tool for Automatic Swiss-Type LathesST-16

Diamond Burnishing Tool for Through Holes " Gorgots-1"ST9-20

Diamond Burnishing Tool for Deep HolesST6-40

1/4