지금 보고 계신 제품의 제조사에요

아이티티캐논

이 기업의 다른 제품

ITT Cannon Cable-to-Cable (CTC) IP69K Connectors

ITT Cannon Trident Multiway Rack & Panel Connectors

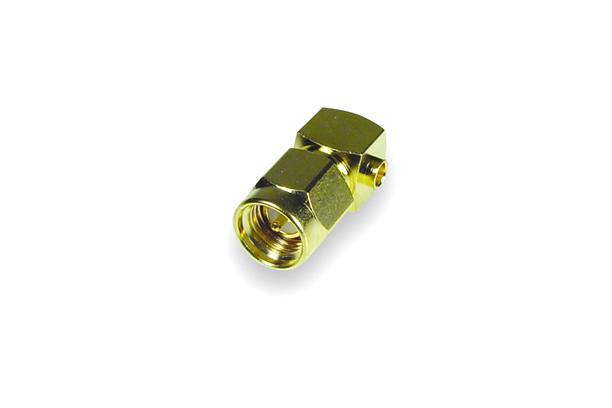

ITT Cannon Selectro RF Coaxial Connectors

ITT Cannon MKJ Series Micro-Miniature Circular Connectors

ITT Cannon MDSM Series Micro-D Connectors

ITT Cannon MDM Series | MIL-DTL-83513 Micro-D Connectors

ITT Cannon SLE Series Snap Lock Connectors

ITT Cannon CLC Series Clip Lock Circular Vector Connectors

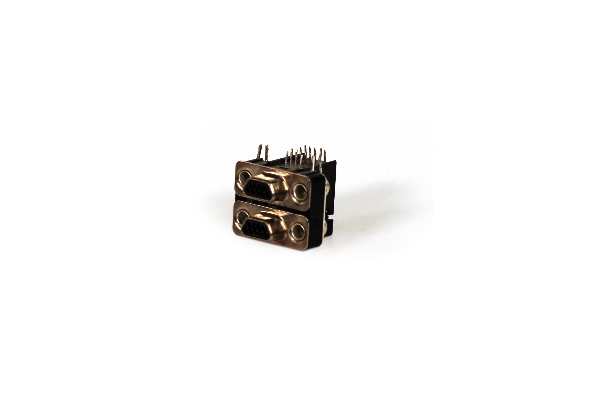

ITT Cannon Space Grade D-Sub Connectors | DNM & DNMB Series

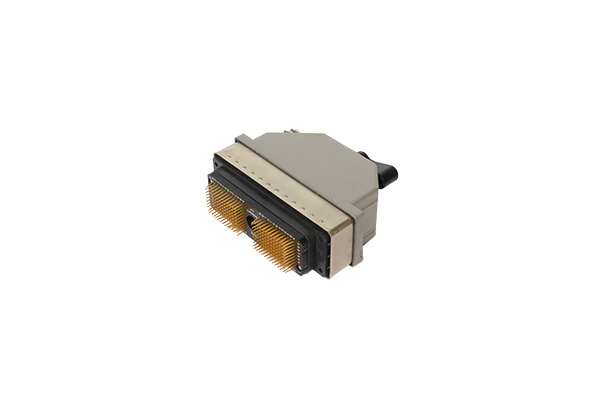

Zero Insertion Force (ZIF) Connectors | ITT Cannon DL Series

ITT Cannon BKA ARINC 600 Aerospace Connectors

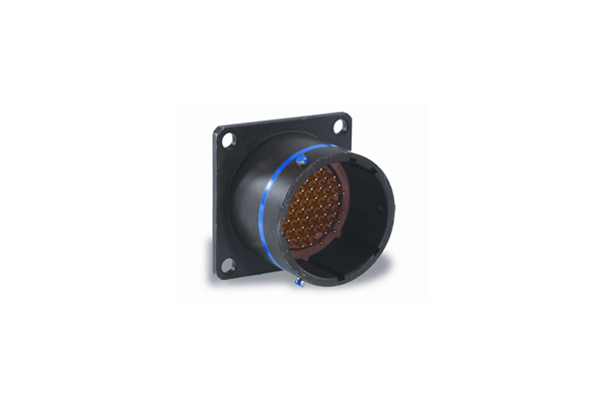

ITT Cannon KJB Series 38999-Style Series III Miniature Circular Connectors

ITT Cannon KJL Series 38999-Style Series I Miniature Circular Connectors

ITT Cannon VEAM PT Connector Series

D-Sub High Reliability Connectors by ITT Cannon

ITT Cannon APD Series Connectors

1/4