지금 보고 계신 제품의 제조사에요

HORIBA

구매정보

HORIBA

정보 인증을 완료한 신뢰할 수 있는 기업입니다.

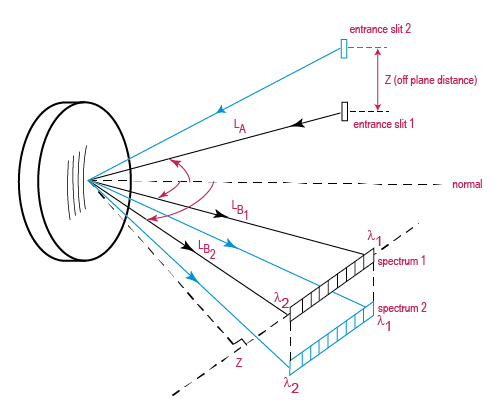

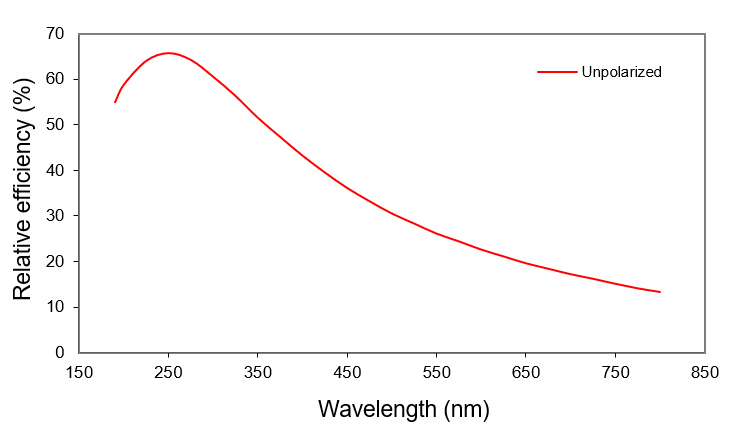

분광기, 분광 시스템, 그레이팅, 회절격자, 카메라 시스템, OEM 제조업체

연락처

+33 1 69 74 72 00

이메일

info-sci.fr@horiba.com

상품정보에 문제가 있나요?

정보수정 / 삭제요청

코머신은 제품 판매자가 아닙니다.법적고지 및 안내

제품 상세 정보

이 기업의 다른 제품

Multispectral Imaging SpectrometerLumetta

Hyperspectral Imaging SystemsPoliSpectra® H116

MultiTrack SpectrometerPoliSpectra® Quad

MultiTrack SpectrometerPoliSpectra® M116

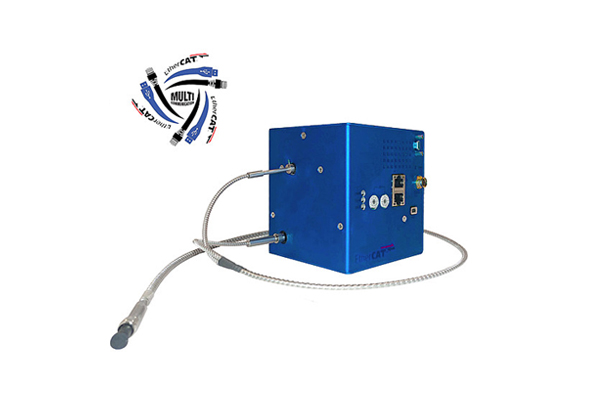

UV-Vis-NIR SpectrometersInVizU Cube

UV-Vis-NIR SpectrometersVS70-MC

UV-Vis-NIR SpectrometersOES-Star

UV-Vis-NIR SpectrometersVS70-PDA

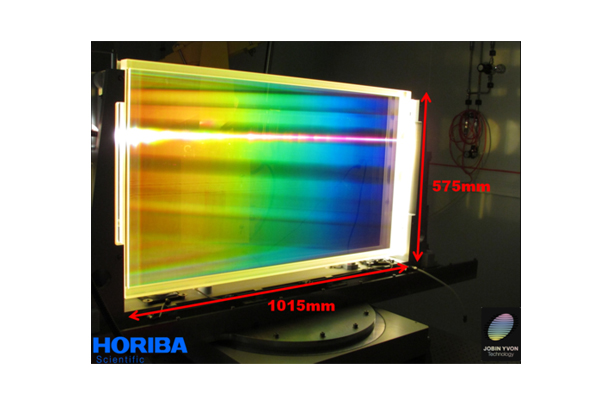

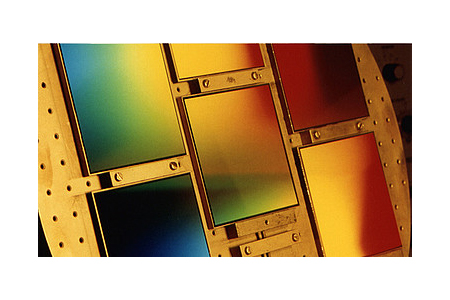

Gratings for astronomy

Laser Pulse Compression Gratings

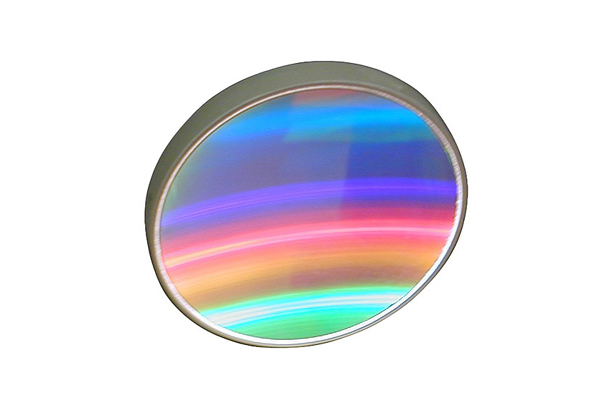

Holographic Concave Gratings - Type I

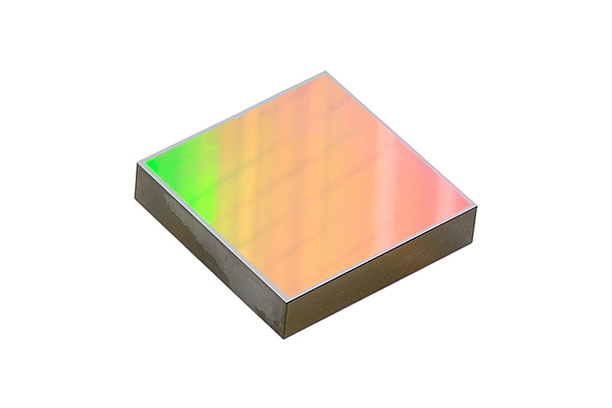

Ruled plane gratings

Blazed Holographic Plane Gratings

Holographic Plane Gratings

Scientific CMOS Imaging CameraSylent™

Syncerity Scientific CamerasFI-VU-VIS

1/4