지금 보고 계신 제품의 제조사에요

암페놀

제품 상세 정보

이 기업의 다른 제품

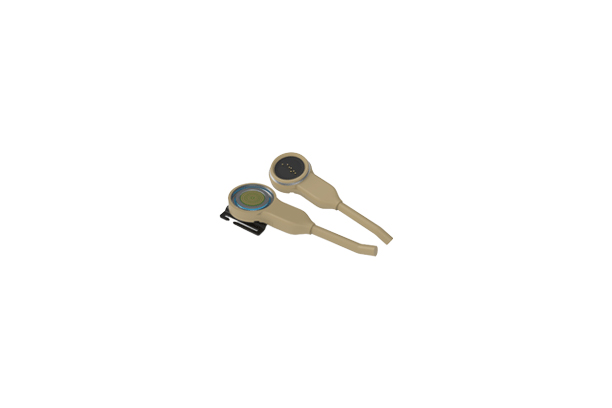

Amphenol NEXUS Plug and Jack Telephone Connectors

Amphenol NEXUS M55116 MIL-Spec Audio Connectors

Stingray 7 Series

Amphenol Series Five Connectors

Amphenol Micro-D M83513 Connectors

Amphenol R-VPX Evolution Series

Amphenol NEXUS Plug and Jack Microphone Connectors

Amphenol NEXUS Waterproof Push-Button Switches

Amphenol Communication Solutions (ACS) RJHSE Modular Jack Connectors

Amphenol Tuchel 44 Series Connectors

Amphenol Sine Systems DuraMate™ AHDP Isobus 91 Series

Amphenol ecomate® RM Connectors

Amphenol Pcd Rack & Panel Type D-Sub Connectors

Amphenol USBFTV (USB-A) Series Connectors

Amphenol Ruggedized Ethernet Connectors (Pulse-Net)

Amphenol OCS High-Speed Connectors (Oval Contact System)

1/4