Partners

Sort by

RMKorea

Rotary joint, Swivel joint, Mechanical seal

RealSYS

Converter, LAN communication etc.

RADIANi

Measurement sensors, Measurement equipment, Electric balancer

Qingdao Zhurui Industry & Trading

Casters

POSTECH

Rotary sensor, Linear sensor, Magnet sensor etc.

PORA ELECTRIC MACHINERY

Automatic tension controller, Infrared sensor, Powder break etc.

PN POONGNYUN

Air fryer, Kitchen scissors, Kitchen appliance

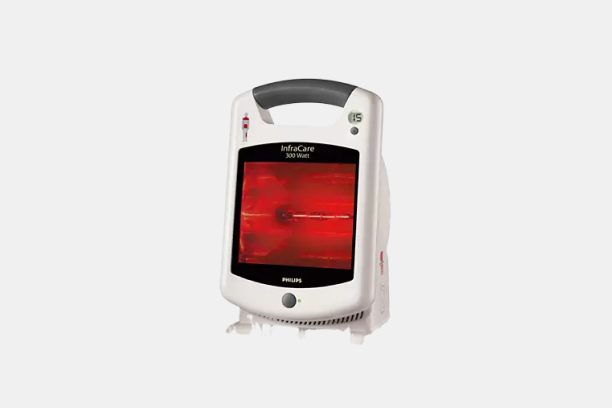

PHILIPS KOREA

의료 장비, 전자 현미경, 소형 가전 등

NURITECH

Flow Meter, Pressure Transmitter, Temperature Sensor etc.

NOVIS KOREA

Anti-vibration supplies, anti-noise supplies, and rubber products etc.