This product is manufactured by

THERMONIK

Manufacturer information

THERMONIK

Furnace Manufacturer, Graphite Furnace, Metal Furnace, GPS & Hot Press and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

THERMONIK

Product Type

Machine

Brand

-

SKU

142087

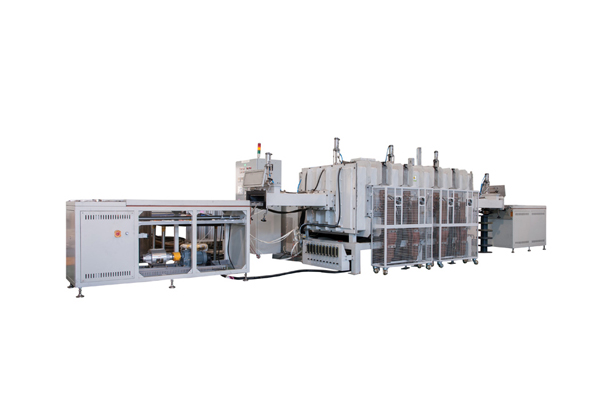

Product Name

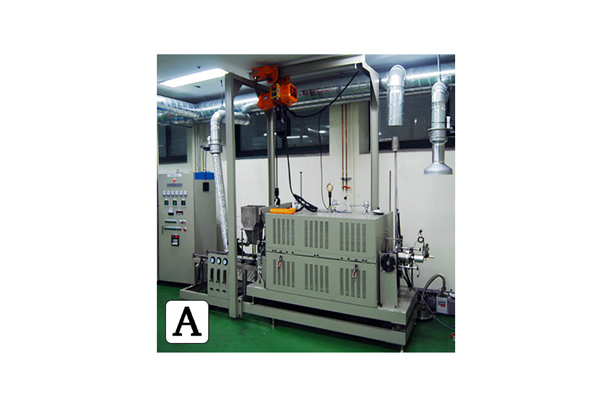

Pusher-style Square Continuous Furnace

Model Name

TNRST-2000

Size

-

Weight

-

Product Details

More products

MoSi2 FurnaceTNBKF-20SK, TNBKF-30SK, TNBKF-40SK

Bogie Elevating Type Large-sized High-temperature FurnaceTNEKF - 17Ⅱ, TNEKF - 17Ⅲ, TNEKF - 17Ⅳ, TNEKF - 17 Ⅴ, TNEKF - 17Ⅵ

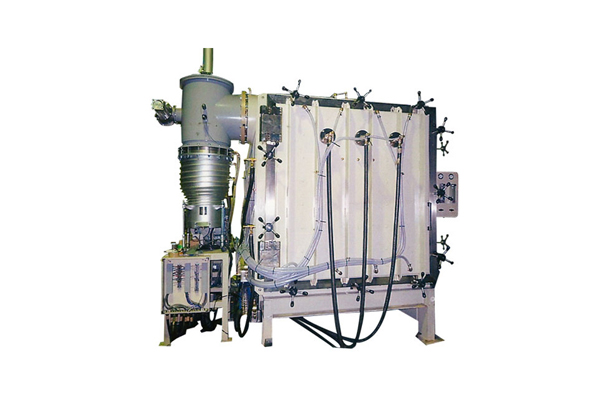

Bogie Elevating Type High Temperature Vacuum FurnaceTNERT, EFD - 20M, EFD - 30M, EFD - 40M

Single Arc Furnace

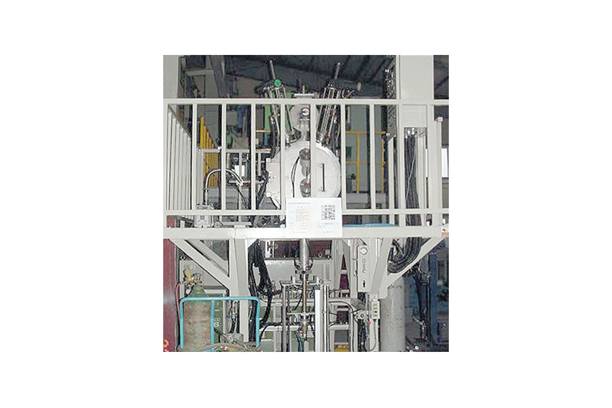

Six Faces Heater Type (Square Type Chamber)TNGF-4609

Single Crystal Growth Furnace

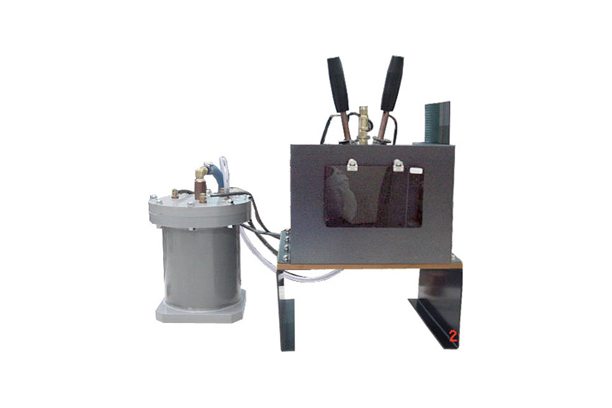

Tri Arc Furnace for Experiment

Tri Arc Furnace for Mass Production

Elevating Type Degreasing MachineEDWF-1260

N2 Atmosphere Multi-FurnaceN2AF - 3RP

Rotary KilnTNRK 1200K1

Rotary KilnTNRK 1100K1

Rotary KilnTNRK 1500M

Chain block method Rotary KILN

Batch Type Al2O3 Tube Rotary Kiln

Kanthal A1 Tube FurnaceTFQ-7-100K1

1/4