Cooling tower manufacturer, Packaging type cooling tower, Industrial cooling tower, A/S, Supplying and more

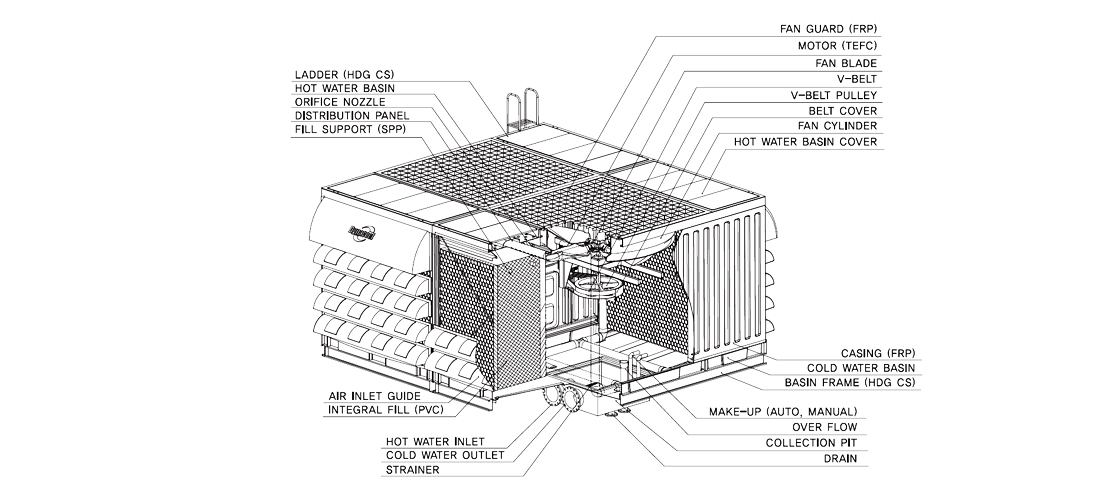

MEX-TOWER Structure chart

Features of EX/MEX-TOWER

1. Extreme-Compact, Light-Weight

EX/MEX series of the cooling tower follows cross-flow system. This is a new innovated system which covers a large capacity in compact type.

2. Extraordinary Technology

The standard cross-flow cooling tower system contains a following disadvantage: the dead area where the cooling water passing through the fill material is deflected to one side. It is due to the speed of the air being sucked and not being cooled. However, the high efficient fill material of the EX/MEX series of the cooling tower system is patented through the extraordinary technology, and does not contain disadvantages.

3. Excellent Anti-Drift System

The usage of PVC cellular type drift eliminator and wide mounting space reduces drift to less than 0.002%. Additionally, it is the least drift type among the cooling tower systems with having low probability of legionella propagation.

4. Maximization of heat exchange efficiency

To maximize heat exchange efficiency, a separate distribution equipment is installed on the top of the fill material. Cooling Tower Institute(CTI) has been proven compact, light weight of the high performanced cooling tower. And it has maximum capacity of 1200 CRT per cell.

5. Driver-Oriented Design

Double Cross Flow system cooling tower allows maintenance and repair during the operation. Access door is designed for easy access, built efficient to inspect and clean. Also, immediate repair is possible when defects occur on the driving side.

6. Semi-Permanent Use

Ultraviolet protection coating (UV coating) is applied to the fill material to minimize the hardening phenomenon. Therefore, it does not interfere with the related system (main equipment, pump, piping) due to breakage.

ECO-DYNA COOL Structure chart

Features of ECO-DYNA COOL

1. Compact Design

All of ventilation fan, cylinder, and piping is installed inside of the cooling tower system. Therefore, eliminates the cost caused by the external piping installation and does not interfere with the external peripheral equipment.

2. Low noise, Low vibration

The installation of the driving unit is created through selecting the best direction and considering its’ vibration. The center of the gravity is minimized as much as possible through the stable operation with utilizing low-balance design of the cooling tower system.

3. Economical Energy-Miser System

TEAO is dedicated to evaporative cooling and it can be installed by selecting the pole change and inverter motor. So, when the ambient temperature is low due to day/night, or seasonal temperature changes, an eco-friendly green cooling tower’s Energy-Miser System, which is generated by unnecessary waste of power, reduces the amount of carbon.

4. Maximization of thermal performance and reduction of maintenance cost

Since the ventilation fan is designed to optimum installation position, it maximizes the intake amount of air to the fill material and induces smooth circulation of air from the bottom to the top of the fill material by installing the multi-inlet air guide. It is a groundbreaking cooling tower system by minimizing the dead area but also maximizing the efficiency.

5. Space-Saving Cooling Tower

If a cooling tower system is installed in a noise-sensitive area such as a densely populated area or a library, a silencer is installed after installing an additional device for installing a silencer in the existing cooling tower. ECO-DYNA COOL cooling tower, however, does not need any additional equipment nor require additional cost during the installation therefore, results in cost-saving.