This product is manufactured by

K-SYSTEMS-TOBOL

Manufacturer information

K-SYSTEMS-TOBOL

Verified & Trusted Manufacturer

Diamond burnishing tools and roller burnishing tools Manufacturer, Sensor Tool

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

K-SYSTEMS-TOBOL

Product Type

Machine

Brand

-

SKU

135576

Product Name

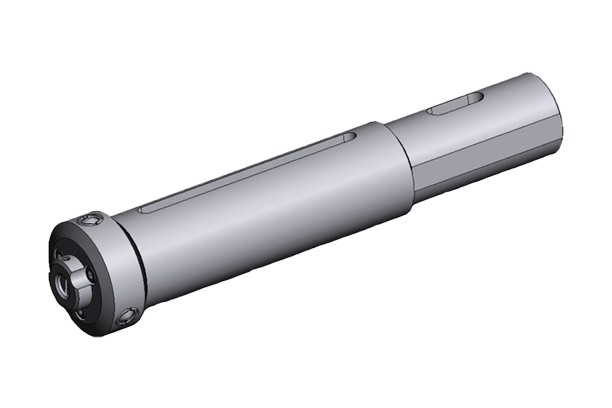

Roller Burnishing Tool for Holes

Model Name

STR-8

Size

-

Weight

-

Product Details

More products

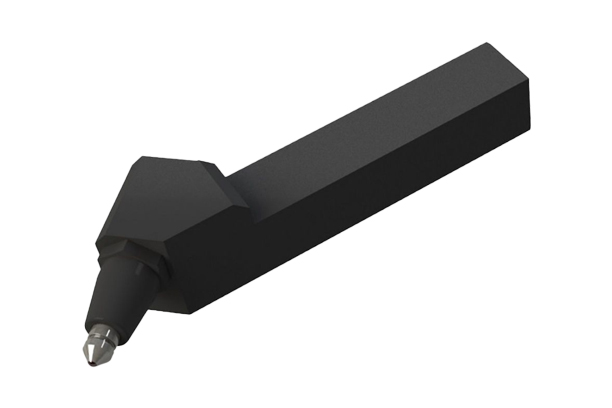

Single-Roller Burnishing Tool for Angle Surface SuperfinishingSTR3-02, STR3-02R, STR3-02L

Single-Roller Burnishing Tool for External Surface Superfinishing ProcessingSTR3-01, STR3-01R, STR3-01L

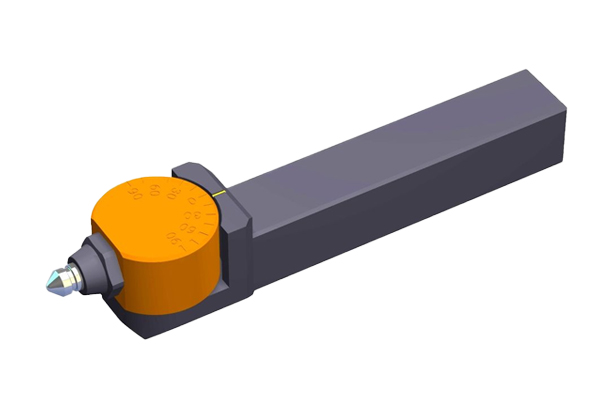

Diamond Burnishing Tool for Plain Surfaces Burnishing MillST-11, ST11-47

Burnishing Tool for Radius, Angle and Steplike SurfacesST7-25L, ST7-25R

Cutting Tool for Hard Turning with CoolingST-22

Combined Skiving and Roller Burnishing Tool 2 in 1STGA-T

Roller Burnishing Tool for Large HolesSTR8-180

Diamond Burnishing Tool for Hydraulic Cylinder LinersST-12

Single-Roller Universal Rolling Burnishing Tool for Machining External Surfaces, Faces and HolesSTR-5

Ball Burnishing and Surface Hardening Tool for HolesSTR-2

Ball Burnishing and Surface Hardening ToolSTR-1

Universal Rotatable Diamond Burnishing ToolST-21

Diamond Burnishing Tool for Automatic Swiss-Type LathesST-16

Diamond Burnishing Tool for Through Holes " Gorgots-1"ST9-20

Diamond Burnishing Tool for Deep HolesST6-40

1/4