Overview

- Summary

- APIS Co., Ltd. is a technology-innovative company specializing in PVD (Physical-Vapor Deposition) equipment based on Ion Plasma Technology, focusing on the development and supply of thin-film coating and ion implantation devices. The company possesses the capability to provide high-quality thin-film solutions to various industries through its large-area In-Line Coating mass production equipment and Hybrid Arc Ion Plating systems. Leveraging ion beam irradiation technology transferred from the Korea Atomic Energy Research Institute, it holds capabilities in developing next-generation industrial ion beam equipment and manufacturing automated mass production facilities.APIS Co., Ltd. is a technology-innovative company specializing in PVD (Physical-Vapor Deposition) equipment based on Ion Plasma Technology, focusing on the development and supply of thin-film coating and ion implantation devices. The company possesses the capability to provide high-quality thin-film solutions to various industries through its large-area In-Line Coating mass production equipment and Hybrid Arc Ion Plating systems. Leveraging ion beam irradiation technology transferred from the Korea Atomic Energy Research Institute, it holds capabilities in developing next-generation industrial ion beam equipment and manufacturing automated mass production facilities.

- Key Products/Technologies

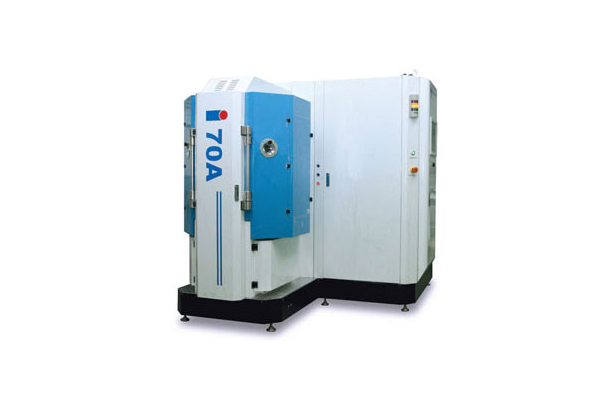

- Hybrid Arc System (i90A, i300A, i70A, i70S, i200A, i150A, i40A, i40S, i120A): Thin-film coating systems for various applications such as inserts and hobs, large products and broaches, quick cycle time coating, broaches, pistons and decoration coating, large die-casting and injection molds, R&D, scribers, micro-tools, and EDR and mold coating.Hybrid Arc System (i90A, i300A, i70A, i70S, i200A, i150A, i40A, i40S, i120A): Thin-film coating systems for various applications such as inserts and hobs, large products and broaches, quick cycle time coating, broaches, pistons and decoration coating, large die-casting and injection molds, R&D, scribers, micro-tools, and EDR and mold coating.

- Hybrid Arc Ion Plating and New CD Mass Production Equipment: Technology for improving productivity through the development and supply of large-area In-Line Coating mass production equipment.Hybrid Arc Ion Plating and New CD Mass Production Equipment: Technology for improving productivity through the development and supply of large-area In-Line Coating mass production equipment.

- DLC (Diamond-Like Carbon) Mass Production Equipment: Development and supply of DLC coating solutions optimized for fields requiring diverse thin-film properties.DLC (Diamond-Like Carbon) Mass Production Equipment: Development and supply of DLC coating solutions optimized for fields requiring diverse thin-film properties.

- Industrial Ion Beam Irradiation Technology: Possessing capabilities in developing large-area polymer industrial ion beam equipment and manufacturing automated mass production equipment for various applications, based on patented technology transferred from the Korea Atomic Energy Research Institute.Industrial Ion Beam Irradiation Technology: Possessing capabilities in developing large-area polymer industrial ion beam equipment and manufacturing automated mass production equipment for various applications, based on patented technology transferred from the Korea Atomic Energy Research Institute.

- Core Advantages

- Specialized manufacturing capability for PVD devices based on Ion Plasma Technology: Expertise in manufacturing various PVD devices utilizing Ion Plasma Technology.Specialized manufacturing capability for PVD devices based on Ion Plasma Technology: Expertise in manufacturing various PVD devices utilizing Ion Plasma Technology.

- Development capability for large-area In-Line Coating mass production equipment: Design and production technology for large-area coating equipment, including Hybrid Arc systems suitable for large product coating.Development capability for large-area In-Line Coating mass production equipment: Design and production technology for large-area coating equipment, including Hybrid Arc systems suitable for large product coating.

- Patent technology transfer and commercialization from KAERI: Acquisition of patented technology for industrial ion beam irradiation devices from the Korea Atomic Energy Research Institute, leading to the development of large-area polymer industrial ion beam equipment and automated mass production facilities.Patent technology transfer and commercialization from KAERI: Acquisition of patented technology for industrial ion beam irradiation devices from the Korea Atomic Energy Research Institute, leading to the development of large-area polymer industrial ion beam equipment and automated mass production facilities.

- Technological responsiveness to diverse thin-film property requirements: Capability to develop specialized thin films, including the development and supply of DLC mass production equipment.Technological responsiveness to diverse thin-film property requirements: Capability to develop specialized thin films, including the development and supply of DLC mass production equipment.

- Continuous technological development for product quality improvement and cost competitiveness: Efforts in developing various Plasma Sources and Vacuum Components to meet customer demands.Continuous technological development for product quality improvement and cost competitiveness: Efforts in developing various Plasma Sources and Vacuum Components to meet customer demands.

- Recognition of technology and quality in overseas markets: Proven technological and quality competitiveness through equipment exports to leading companies in China and Japan.Recognition of technology and quality in overseas markets: Proven technological and quality competitiveness through equipment exports to leading companies in China and Japan.

- Target Industrie

- Tool Industry: Coating for precision cutting tools such as inserts, hobs, broaches, scribers, and micro-tools, enhancing their lifespan and performance.Tool Industry: Coating for precision cutting tools such as inserts, hobs, broaches, scribers, and micro-tools, enhancing their lifespan and performance.

- Mold Industry: Coating for large die-casting and injection molds, and EDR molds, to improve durability and release properties.Mold Industry: Coating for large die-casting and injection molds, and EDR molds, to improve durability and release properties.

- Automotive Parts Industry: Coating for automotive components like pistons, for wear prevention and surface hardness enhancement.Automotive Parts Industry: Coating for automotive components like pistons, for wear prevention and surface hardness enhancement.

- Decoration Industry: Decorative coatings for various products to improve aesthetics and surface protection.Decoration Industry: Decorative coatings for various products to improve aesthetics and surface protection.

- Research and Development Sector: Supply of coating equipment for R&D purposes, including small tools and specialized thin-film development.Research and Development Sector: Supply of coating equipment for R&D purposes, including small tools and specialized thin-film development.

- Major Markets

- China, JapanChina, Japan

- Certifications/Patents

- Possession of patented technology related to industrial ion beam irradiation devices, transferred from the Korea Atomic Energy Research Institute.Possession of patented technology related to industrial ion beam irradiation devices, transferred from the Korea Atomic Energy Research Institute.

- Continuous efforts in technological development for improving product quality and enhancing cost competitiveness.Continuous efforts in technological development for improving product quality and enhancing cost competitiveness.

- Capability in developing various Plasma Sources, specialized thin films, and other Vacuum Components.Capability in developing various Plasma Sources, specialized thin films, and other Vacuum Components.

- Emphasis on technological competitiveness through the 'Technology Certifications and Patents' section on its homepage.Emphasis on technological competitiveness through the 'Technology Certifications and Patents' section on its homepage.

Introduction

Key Products

Location

76 Deokcheon-ro 48beon-gil, Manan-gu, Anyang, Gyeonggi-do, South Korea

클릭하여 위치 살펴보기