Overview

- Summary

- A specialized manufacturer of stud welding machines, HANYANG STUD WELDING focuses on stud welding systems for the automotive, shipbuilding, construction, and plant industries. The company strives to become a world-class enterprise with competitiveness through continuous research and development and the creation of high-quality products. It enjoys a strong reputation for supplying products to domestic and international finished vehicle factories and various affiliates. The company integrates Korea's advanced IT industry and cutting-edge technologies into its welding solutions, adapting to the era of globalization.A specialized manufacturer of stud welding machines, HANYANG STUD WELDING focuses on stud welding systems for the automotive, shipbuilding, construction, and plant industries. The company strives to become a world-class enterprise with competitiveness through continuous research and development and the creation of high-quality products. It enjoys a strong reputation for supplying products to domestic and international finished vehicle factories and various affiliates. The company integrates Korea's advanced IT industry and cutting-edge technologies into its welding solutions, adapting to the era of globalization.

- Key Products/Technologies

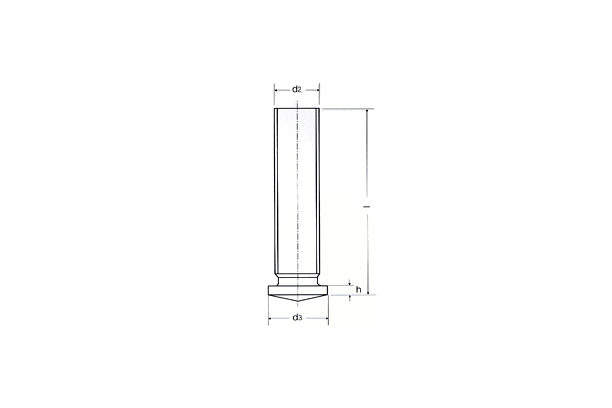

- Automotive Industrial Welding Stud product line includes SC-B (Threaded Stud), SC-Z (Fir Tree Stud), T-Stud, W-Top, SC-S (No-Thread Stud), MR (Reduced Base Stud), MP-DUO (Bi-metallic Threaded Stud), MI (Tapped Stud), S (No-Thread Stud), IS (Insulation Pin), and R (Insulation Clips).Automotive Industrial Welding Stud product line includes SC-B (Threaded Stud), SC-Z (Fir Tree Stud), T-Stud, W-Top, SC-S (No-Thread Stud), MR (Reduced Base Stud), MP-DUO (Bi-metallic Threaded Stud), MI (Tapped Stud), S (No-Thread Stud), IS (Insulation Pin), and R (Insulation Clips).

- Automotive Stud Welding System product models include HY-7 DELUXE (For T-stud), HY-F500, HY-R550; HY-7 DELUXE (ROBOT), HY-F600, HY-R1000; SW 850-2A (Only for T-Stud), HY-F500, HY-G550; SW 1400-2A (Semi Auto System), HY-F600, HY-G650; and SW 1800-2A, SW 1400-2A (Robot), HY-F600, HY-R750, offering diverse automated welding systems.Automotive Stud Welding System product models include HY-7 DELUXE (For T-stud), HY-F500, HY-R550; HY-7 DELUXE (ROBOT), HY-F600, HY-R1000; SW 850-2A (Only for T-Stud), HY-F500, HY-G550; SW 1400-2A (Semi Auto System), HY-F600, HY-G650; and SW 1800-2A, SW 1400-2A (Robot), HY-F600, HY-R750, offering diverse automated welding systems.

- Stud Welding System & Controls product models include CD-W-100, CD-10 GUN (Only for CD-stud); SW 850A, NSA-40B-1; SW 500A, NSA-40B-1; SW 1400A, NSA-40B-3; and SW 2800A, NSA-20B HD Gun, encompassing various control systems and welding machines.Stud Welding System & Controls product models include CD-W-100, CD-10 GUN (Only for CD-stud); SW 850A, NSA-40B-1; SW 500A, NSA-40B-1; SW 1400A, NSA-40B-3; and SW 2800A, NSA-20B HD Gun, encompassing various control systems and welding machines.

- The HY-7 DELUXE (ROBOT) Power Unit features a 3-phase 220V/380V/440V input voltage, a welding current range of 400-1400A, a welding time range of 20ms-90ms, compatibility with 3mm-8mm studs, and a continuous welding capacity of approximately 40 welds per minute for 6mm diameter studs.The HY-7 DELUXE (ROBOT) Power Unit features a 3-phase 220V/380V/440V input voltage, a welding current range of 400-1400A, a welding time range of 20ms-90ms, compatibility with 3mm-8mm studs, and a continuous welding capacity of approximately 40 welds per minute for 6mm diameter studs.

- The SW 850-2A Power Unit offers a 3-phase 220V/380V/440V input voltage, a welding current of 100-850A, a welding time of 0.01-1.0 seconds, and a lightweight body of 53.4kg.The SW 850-2A Power Unit offers a 3-phase 220V/380V/440V input voltage, a welding current of 100-850A, a welding time of 0.01-1.0 seconds, and a lightweight body of 53.4kg.

- CD Type stud welding technology involves storing electrical energy in a capacitor to generate arc heat, with the welding gun's spring pressure facilitating the joint. This method achieves short welding times of 3-6ms in contact mode and 6-15ms in gap mode.CD Type stud welding technology involves storing electrical energy in a capacitor to generate arc heat, with the welding gun's spring pressure facilitating the joint. This method achieves short welding times of 3-6ms in contact mode and 6-15ms in gap mode.

- The company possesses various welding process technologies, including Drawn Arc Process (DA Type) and Short Cycle Process (SC Type). Enhanced productivity through the development of automatic lifting welding guns and automatic feeder motor drive systems.The company possesses various welding process technologies, including Drawn Arc Process (DA Type) and Short Cycle Process (SC Type). Enhanced productivity through the development of automatic lifting welding guns and automatic feeder motor drive systems.

- Core Advantages

- Continuous efforts to develop the highest quality products suitable for the era of globalization and a vision to grow into a world-class enterprise.Continuous efforts to develop the highest quality products suitable for the era of globalization and a vision to grow into a world-class enterprise.

- Capability to integrate Korea's leading IT industry and advanced technologies into stud welding solutions, providing innovative offerings.Capability to integrate Korea's leading IT industry and advanced technologies into stud welding solutions, providing innovative offerings.

- Securing skilled research personnel and establishing a corporate R&D center for continuous research and development, strengthening technological competitiveness.Securing skilled research personnel and establishing a corporate R&D center for continuous research and development, strengthening technological competitiveness.

- Attainment of ISO 9001 quality management system certification, CE certification, selection as an innovative small and medium-sized enterprise (INNO-BIZ), and venture company certification, ensuring technological prowess and reliability.Attainment of ISO 9001 quality management system certification, CE certification, selection as an innovative small and medium-sized enterprise (INNO-BIZ), and venture company certification, ensuring technological prowess and reliability.

- High market recognition and trust, having supplied products to domestic and international finished vehicle factories and various affiliates for a long time.High market recognition and trust, having supplied products to domestic and international finished vehicle factories and various affiliates for a long time.

- A strategic partnership with IVOSTUD GmbH in 2021, expanding business areas in automotive and industrial manufacturing and creating synergy through collaboration with a global technology leader.A strategic partnership with IVOSTUD GmbH in 2021, expanding business areas in automotive and industrial manufacturing and creating synergy through collaboration with a global technology leader.

- Protection of proprietary technology and a leading technological position through patents and utility model registrations for stud welders and robot guns.Protection of proprietary technology and a leading technological position through patents and utility model registrations for stud welders and robot guns.

- A strong commitment to customer satisfaction, taking full responsibility for transactions and striving to meet customer needs, building trust.A strong commitment to customer satisfaction, taking full responsibility for transactions and striving to meet customer needs, building trust.

- Target Industrie

- Automotive industryAutomotive industry

- Shipbuilding industryShipbuilding industry

- Construction industryConstruction industry

- Plant industryPlant industry

- Industrial manufacturing sectorIndustrial manufacturing sector

- Major Markets

- South Korea (domestic market leader), China (communication through multilingual website)South Korea (domestic market leader), China (communication through multilingual website)

- Germany (strategic partnership with IVOSTUD GmbH)Germany (strategic partnership with IVOSTUD GmbH)

- Certifications/Patents

- CE certification mark acquisition (January 2007)CE certification mark acquisition (January 2007)

- Venture company certification (December 2006)Venture company certification (December 2006)

- Selection as an innovative small and medium-sized enterprise (INNO-BIZ) (November 2006)Selection as an innovative small and medium-sized enterprise (INNO-BIZ) (November 2006)

- ISO 9001 certification acquisition (August 2004)ISO 9001 certification acquisition (August 2004)

- Patents and utility model registrations for Stud Welder and Robot Gun (April 2004)Patents and utility model registrations for Stud Welder and Robot Gun (April 2004)

Introduction

Key Products

Location

197 Jeongwangcheon-ro, Siheung-si, Gyeonggi-do, South Korea

클릭하여 위치 살펴보기