This product is manufactured by

CHOWEL

Manufacturer information

CHOWEL

Welding machine, Automation system, Transformer, Control device and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

CHOWEL

Product Type

Machine

Brand

-

SKU

30136

Product Name

Inverter Pulse Mig Welding Machine

Model Name

SA-350P, 500P

Size

-

Weight

-

Product Details

More products

Portable Spot Welding TransformerPA-125, 150, 180, 200

DC Inverter Transformer For RobotIT-77, 101, 127

Inverter Air Spot Welding MachineIASP-Series

Fool-Proof EquipmentCWFP-Series

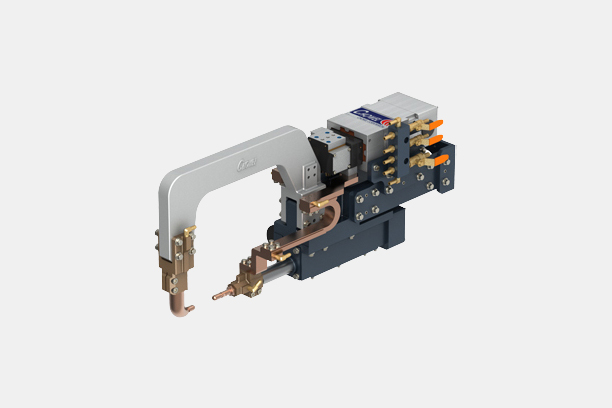

Resistance Welding Gun

Adaptive Controller PartWELCOM 1000

DC Inverter Welding Controller PartWelcom-Series

Gantry Welding Machine for Railway Car Assembly

Mash Seam Welding Machine

Inverter Arc Welding MachineNT-350

AC Welding Controller PartAC-Series

Roll Spot Welding Machine

Coil Spot Welding Machine

Inverter Arc Welding MachineSA-Series

IC+Thyristor Type Arc Welding MachineBA-Series

Integrated Quality Network System

1/4