Interconnect Product Manufacturer, Electrical, Electronic, Fiber Optic Connectors, Coaxial Cable and more

HIGH DENSITY CONNECTORS RATED TO 38999 SPEC

The 38999 family of high-density connectors was designed to work with existing MIL-Spec 38999 shells. To the end users familiar with standard 38999 connectors, this family of high-density connectors will look, feel, and perform just like the MIL-Qualified connectors. Utilizing an existing MIL-Spec 39029 size 23 contact and MIL-Spec shells, the new system is usually a drop-in connector. Even though this high-density connector has 30% more contacts, it still performs to the minimum electrical requirements of standard 38999 connectors.

Features

- High-Reliability

HD38999 - TV style connectors are used in some of the most rigorous environments and must perform flawlessly under wide temperature ranges, high vibrations and be resistant to a vast array of contaminants. Visual confirmation of mating is provided by the plug coupling nut covering a red band on the mating shell. - Outstanding Emi-Shielding Protection

These connectors provide excellent signal integrity due to the shielded mating system that utilizes 360-degree shell grounding fingers, providing protection of up to 65 dB at 10 GHz. - Operates At Extreme Temperatures

These connectors operate in temperatures from -85°F to +392°F (-65°C to +200°C). - High-Density Connectors

If space is at a premium, HD38999 - TV connectors offer up to 187 contacts per connector. Ideally suited for the demands of digital electronics on fly-by wire aircraft, advanced robotics, and critical industrial equipment. - Self-Locking Connector Systems

Self-locking coupling nuts and self-locking endbell accessory hardware provide the best performance for threaded connectors in high-vibration applications. - Broad Range Of Military And Commercial Accessories

Many military-standard endbells to M85049 specifications and a wide array of cable termination styles are available. Straight, 45 and 90-degree endbells come in many styles from cost-effective standard clamp to shielded, environmentally-sealed and everything in between. - Contact Protection

TV connectors are designed to be scoop-proof. Pin contacts are recessed to prevent contact damage and contact shorting when connector halves are mated.

Materials & Finishes

Shell & Plating

Electrical Data

Contact Sizes 23

Operating Voltage & Test Voltage (Unmated Condition)

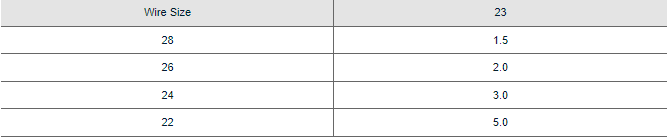

Current Rating by Contact Size & Wire Accommodation (Test Amps)

Contact Resistance of Mated Contacts End to-End

Mechanical

Wire Sealing Range

Insulation Strip Length

All dimensions in inches (millimeters in parentheses)

Finish W52: 48-hour

Finish F: 48-hour per MIL-STD-1344A method 1001 condition B

Finish J & M: 1000-hour per MIL-STD-1344A method 1001 condition C

Finish S & K: 500-hour per MIL-STD-1344A method 1001 condition C

Finish DT & DZ: 500-hour

Finish DT, M, K & S: 200°C (392°F)

Finish J, W52 & DZ: 175°C (347°F)

Polarization Five keyways with optional master keyway rotations (Note: insert and main keyways remain fixed)

Cross-Section