This product is manufactured by

AMPHENOL

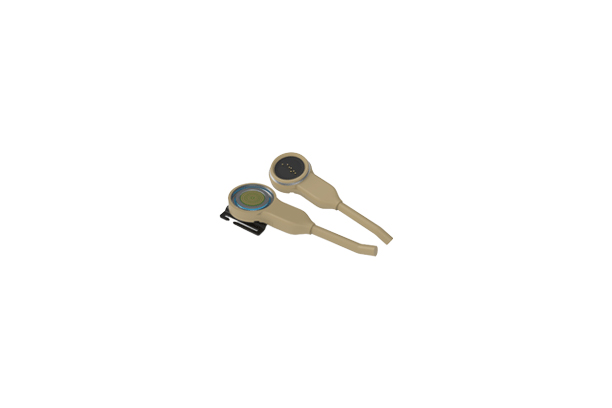

Amphenol Amphe-EX™ Explosion Proof Connectors

Model Name

-

Manufacturer information

AMPHENOL

Interconnect Product Manufacturer, Electrical, Electronic, Fiber Optic Connectors, Coaxial Cable and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

AMPHENOL

Product Type

Machine

Brand

-

SKU

141510

Product Name

Amphenol Amphe-EX™ Explosion Proof Connectors

Model Name

-

Size

-

Weight

-

Product Details

More products

Amphenol NEXUS Plug and Jack Telephone Connectors

Amphenol NEXUS M55116 MIL-Spec Audio Connectors

Stingray 7 Series

Amphenol Series Five Connectors

Amphenol Micro-D M83513 Connectors

Amphenol R-VPX Evolution Series

Amphenol NEXUS Plug and Jack Microphone Connectors

Amphenol NEXUS Waterproof Push-Button Switches

Amphenol Communication Solutions (ACS) RJHSE Modular Jack Connectors

Amphenol Tuchel 44 Series Connectors

Amphenol Sine Systems DuraMate™ AHDP Isobus 91 Series

Amphenol ecomate® RM Connectors

Amphenol Pcd Rack & Panel Type D-Sub Connectors

Amphenol USBFTV (USB-A) Series Connectors

Amphenol Ruggedized Ethernet Connectors (Pulse-Net)

Amphenol OCS High-Speed Connectors (Oval Contact System)

1/4