This product is manufactured by

UIL ULTRASONIC

Manufacturer information

UIL ULTRASONIC

Industrial Ultrasonic Cleaner Manufacturer, Ultrasonic Transducer, Generator and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

UIL ULTRASONIC

Product Type

Machine

Brand

-

SKU

142473

Product Name

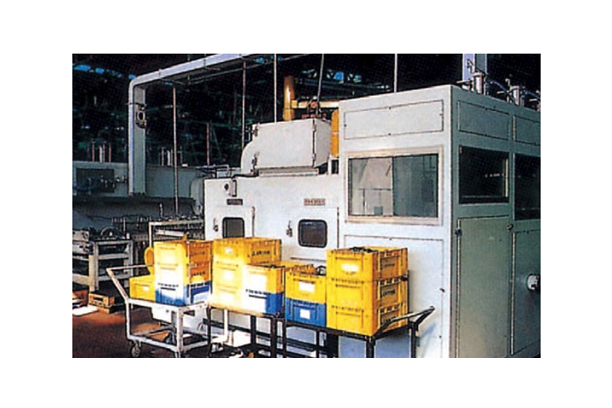

Metal Mask Ultrasonic Cleaner

Model Name

-

Size

-

Weight

-

Product Details

More products

Air Cooled Chiller - Separate TypeSJ-05AS, SJ-075AS, SJ-10AS, SJ-15AS, SJ-20AS, SJ-30AS, SJ-40AS

Air Cooled Chiller - Integrated TypePA-01A, PA-02A, PA-03A, PA-05A, PA-075A, PA-10A, PA-15A, PA-20A, PA-30A, PA-40A

Electrolysis Ultrasonic CleanerUIL - M10, UIL - M20, UIL - M36

Water Soluble Multi Tank Ultrasonic CleanerUIL-2W-1200W, UIL-2W-2400W, UIL-3W-2400W, UIL-4W-3600W, UIL-5W-3600W

Tabletop Ultrasonic CleanerDHP-50040-WIA, DHP-50040-ORA, DHP-50040-IVA, DHP-50040-SBA

Tabletop Ultrasonic Cleaner (Digital ABS Series)DHP40040-WIA, DHP40040-ORA, DHP40040-IVA, DHP40040-SBB

Tabletop Ultrasonic Cleaner (Digital ABS Series)DHP-30040-WIB, DHP-30040-ORB, DHP-30040-IVB, DHP-30040-SBB

Ultrasonic GeneratorUIL-400TD, UIL-600TD, UIL-900TD, UIL-1200TD, UIL-1500TD

Hot Air Dryer

Semiconductor Chiller & Special Type

Hydrocarbon Ultrasonic Cleaner

Spindle Cleaner

Pitch and Roll Ultrasonic Cleaner

Degassing Ultrasonic Cleaner

Fully Automatic Ultrasonic Cleaner

Fully Automatic Ultrasonic Cleaner

1/4