Overview

- Summary

- TECHPAP, a commercial company established by the French Pulp and Paper Research Center (CTP), specializes in providing laboratory equipment and online sensors globally. Its core business involves quality monitoring and process optimization solutions for the pulp and paper industry. With over 20 years of experience and leveraging the advanced research capabilities of CTP and INPG-PAGORA, the company delivers innovative and precise measurement technologies. These systems contribute significantly to enhancing productivity and strengthening quality control for its clients worldwide.TECHPAP, a commercial company established by the French Pulp and Paper Research Center (CTP), specializes in providing laboratory equipment and online sensors globally. Its core business involves quality monitoring and process optimization solutions for the pulp and paper industry. With over 20 years of experience and leveraging the advanced research capabilities of CTP and INPG-PAGORA, the company delivers innovative and precise measurement technologies. These systems contribute significantly to enhancing productivity and strengthening quality control for its clients worldwide.

- Key Products/Technologies

- Mottling Sensor-Kheops: A laboratory sensor for evaluating offset print quality, print mottle, coating application quality, and surface roughness of paper and board. It utilizes a CCD camera and two specially designed light sources for precise surface roughness and print mottle measurement.Mottling Sensor-Kheops: A laboratory sensor for evaluating offset print quality, print mottle, coating application quality, and surface roughness of paper and board. It utilizes a CCD camera and two specially designed light sources for precise surface roughness and print mottle measurement.

- 2D Formation Sensor (Lab & Online): A sensor for paper formation evaluation, based on image analysis technology using a CCD camera and stroboscope. It provides detailed information on floc size distribution, anisotropy, and periodic marks.2D Formation Sensor (Lab & Online): A sensor for paper formation evaluation, based on image analysis technology using a CCD camera and stroboscope. It provides detailed information on floc size distribution, anisotropy, and periodic marks.

- Fiber&Shive Analyzer - MorFi Neo: A fiber morphology analysis device equipped with the latest camera technology and enhanced resolution. It offers comprehensive analysis of fiber characteristics including length, width, kinks, fines, and shives, with precise microfibrillation measurement capabilities. Compliance with ISO/FDIS 16065-2 standard.Fiber&Shive Analyzer - MorFi Neo: A fiber morphology analysis device equipped with the latest camera technology and enhanced resolution. It offers comprehensive analysis of fiber characteristics including length, width, kinks, fines, and shives, with precise microfibrillation measurement capabilities. Compliance with ISO/FDIS 16065-2 standard.

- On Line HR3D: An online sensor for roughness and step height measurement. It employs a non-contact laser beam and a high-resolution digital camera for surface topography measurement, calculating various roughness parameters such as Ra, Sa, Rq, Sq.On Line HR3D: An online sensor for roughness and step height measurement. It employs a non-contact laser beam and a high-resolution digital camera for surface topography measurement, calculating various roughness parameters such as Ra, Sa, Rq, Sq.

- PI Dirt&Shives (Pulp Inspector): An online analysis module for dirt and shives in pulp. It detects all contrasted contaminants (black dirt, white elements, shives) in the pulp flow in real-time.PI Dirt&Shives (Pulp Inspector): An online analysis module for dirt and shives in pulp. It detects all contrasted contaminants (black dirt, white elements, shives) in the pulp flow in real-time.

- 3D Stick: A novel method for macrostickies measurement. It involves 3D morphology determination and stickies identification through Near Infrared Spectroscopy (NIRS), providing non-contact 3D contaminant characterization.3D Stick: A novel method for macrostickies measurement. It involves 3D morphology determination and stickies identification through Near Infrared Spectroscopy (NIRS), providing non-contact 3D contaminant characterization.

- Pulp Inspector (PI): A modular system for continuous online monitoring of pulp. It offers various measurement functions including CSF, color, fibers, dirt and shives, and NIR.Pulp Inspector (PI): A modular system for continuous online monitoring of pulp. It offers various measurement functions including CSF, color, fibers, dirt and shives, and NIR.

- Core Advantages

- Strong R&D Capabilities of CTP and INPG-PAGORA: Continuous technological innovation and product development capabilities based on the expertise and leading research groups of the French Pulp and Paper Research Center (CTP) and INPG-PAGORA engineering school.Strong R&D Capabilities of CTP and INPG-PAGORA: Continuous technological innovation and product development capabilities based on the expertise and leading research groups of the French Pulp and Paper Research Center (CTP) and INPG-PAGORA engineering school.

- Over 20 Years of Extensive Industry Experience: Accumulation of deep experience and know-how in the production and sale of pulp and paper quality monitoring and process optimization equipment for over two decades.Over 20 Years of Extensive Industry Experience: Accumulation of deep experience and know-how in the production and sale of pulp and paper quality monitoring and process optimization equipment for over two decades.

- Innovative and Comprehensive Product Portfolio: A wide range of products encompassing online sensors and laboratory equipment, along with the application of continuous new technologies to provide innovative measurement solutions.Innovative and Comprehensive Product Portfolio: A wide range of products encompassing online sensors and laboratory equipment, along with the application of continuous new technologies to provide innovative measurement solutions.

- High Accuracy and Repeatability in Measurement Solutions: Ability to secure precise and objective measurement results through cutting-edge optical technologies such as CCD cameras, stroboscopes, and laser beams.High Accuracy and Repeatability in Measurement Solutions: Ability to secure precise and objective measurement results through cutting-edge optical technologies such as CCD cameras, stroboscopes, and laser beams.

- Global Sales Network and Customer Support: Worldwide sales through a network of over 20 agents and distributors in major papermaking countries across Europe, America, and Asia, ensuring prompt after-sales service. Efficient customer support system with remote maintenance and diagnostic capabilities.Global Sales Network and Customer Support: Worldwide sales through a network of over 20 agents and distributors in major papermaking countries across Europe, America, and Asia, ensuring prompt after-sales service. Efficient customer support system with remote maintenance and diagnostic capabilities.

- User-Friendly Software and Easy System Integration: Intuitive user interface based on the latest Windows operating system and seamless data transfer capabilities to DCS or data historian systems via OPC server or 4-20mA signals.User-Friendly Software and Easy System Integration: Intuitive user interface based on the latest Windows operating system and seamless data transfer capabilities to DCS or data historian systems via OPC server or 4-20mA signals.

- Target Industrie

- Pulp and Paper Industry: Quality monitoring and optimization of pulp and paper production processes.Pulp and Paper Industry: Quality monitoring and optimization of pulp and paper production processes.

- Printing Industry: Evaluation of offset print quality, print mottle, and coating application quality.Printing Industry: Evaluation of offset print quality, print mottle, and coating application quality.

- Packaging Industry: Quality control of surface roughness and score for board and packaging materials.Packaging Industry: Quality control of surface roughness and score for board and packaging materials.

- Ink Manufacturers and Coating Suppliers: Support for product quality control and development.Ink Manufacturers and Coating Suppliers: Support for product quality control and development.

- Non-woven Industry: Formation analysis of products using the 2D Formation Sensor.Non-woven Industry: Formation analysis of products using the 2D Formation Sensor.

- Cigarette Paper Industry: Evaluation of covering quality or look-through of cigarette paper using the Mottling Sensor-Kheops.Cigarette Paper Industry: Evaluation of covering quality or look-through of cigarette paper using the Mottling Sensor-Kheops.

- Engineered Wood Panel Industry: Roughness and defect detection for engineered wood panels using HR3D.Engineered Wood Panel Industry: Roughness and defect detection for engineered wood panels using HR3D.

- Major Markets

- Vietnam, IndiaVietnam, India

- France, Germany, Austria, SwitzerlandFrance, Germany, Austria, Switzerland

- United StatesUnited States

- Brazil, Chile, EcuadorBrazil, Chile, Ecuador

- Certifications/Patents

- ISO/FDIS 16065-2 Standard Compliance: The MorFi Neo product ensures measurement accuracy and reliability in fiber morphology analysis, adhering to international standards.ISO/FDIS 16065-2 Standard Compliance: The MorFi Neo product ensures measurement accuracy and reliability in fiber morphology analysis, adhering to international standards.

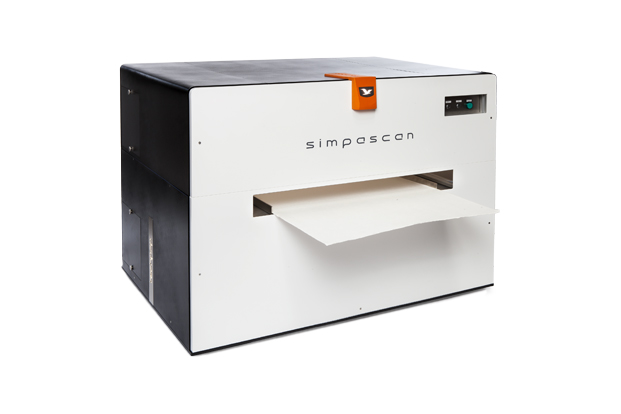

- Measurement System Calibration according to EFPG Standard (CEN/TC 172): Dirt analysis equipment such as Simpalab and SIMPASCAN are calibrated according to European standards.Measurement System Calibration according to EFPG Standard (CEN/TC 172): Dirt analysis equipment such as Simpalab and SIMPASCAN are calibrated according to European standards.

- Joint R&D Capabilities with CTP and INPG-PAGORA: Over 30 years of industry experience in developing customized applications and innovative measurement algorithms, stemming from collaborative research.Joint R&D Capabilities with CTP and INPG-PAGORA: Over 30 years of industry experience in developing customized applications and innovative measurement algorithms, stemming from collaborative research.

- Development of AI Modules: Integration of AI modules for vessel detection and fiber wall thickness measurement into MorFi Neo, along with customer-configurable AI modules, enhancing analytical capabilities.Development of AI Modules: Integration of AI modules for vessel detection and fiber wall thickness measurement into MorFi Neo, along with customer-configurable AI modules, enhancing analytical capabilities.

Introduction

Key Products

Location

1660 Rue de la Piscine, 38610 Gières, France

클릭하여 위치 살펴보기