Overview

- Summary

- TALON TECH is a specialized PR pump company, focusing on the development and supply of precision dispensing systems for semiconductors and high-viscosity liquids. Established in September 2005, the company has built its technological strength based on accumulated know-how in PR pumps and PR sensors. Its core competency lies in precision dispensing technology utilizing DC servo motors. Having relocated to a new facility in June 2021, the company aims to become a world-class leader in the semiconductor PR pump and sensor sectors. The company continuously strives to meet customer demands for quality, service, and price.TALON TECH is a specialized PR pump company, focusing on the development and supply of precision dispensing systems for semiconductors and high-viscosity liquids. Established in September 2005, the company has built its technological strength based on accumulated know-how in PR pumps and PR sensors. Its core competency lies in precision dispensing technology utilizing DC servo motors. Having relocated to a new facility in June 2021, the company aims to become a world-class leader in the semiconductor PR pump and sensor sectors. The company continuously strives to meet customer demands for quality, service, and price.

- Key Products/Technologies

- High Viscosity & High Capacity PR Pumps, including models TP-72S and TP-70BS, are designed for stable transfer and high-volume processing of high-viscosity materials. These pumps feature optimized technology for precise dispensing of high-viscosity liquids essential in semiconductor manufacturing processes.High Viscosity & High Capacity PR Pumps, including models TP-72S and TP-70BS, are designed for stable transfer and high-volume processing of high-viscosity materials. These pumps feature optimized technology for precise dispensing of high-viscosity liquids essential in semiconductor manufacturing processes.

- Color PR Pumps (CIS), with models TP-52R and TP-52S, incorporate specialized technology for stable dispensing of sensitive liquids like color PR. These solutions are suitable for applications requiring precise control and consistent dispense volume.Color PR Pumps (CIS), with models TP-52R and TP-52S, incorporate specialized technology for stable dispensing of sensitive liquids like color PR. These solutions are suitable for applications requiring precise control and consistent dispense volume.

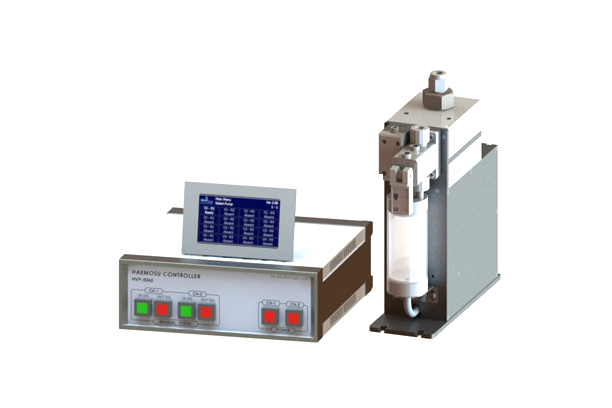

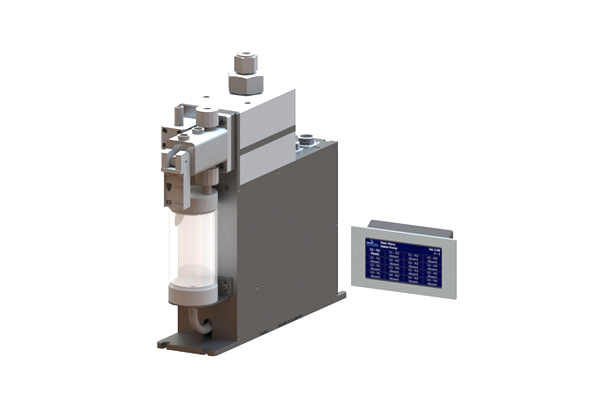

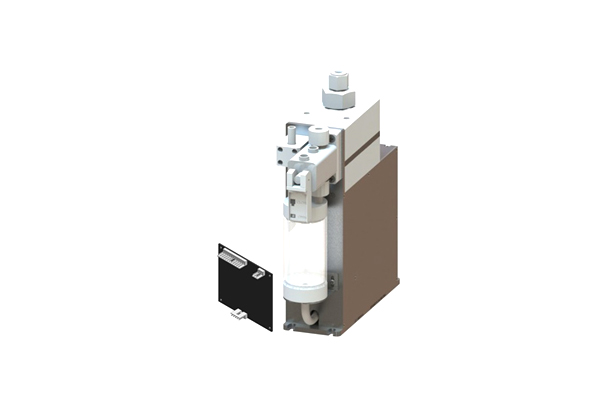

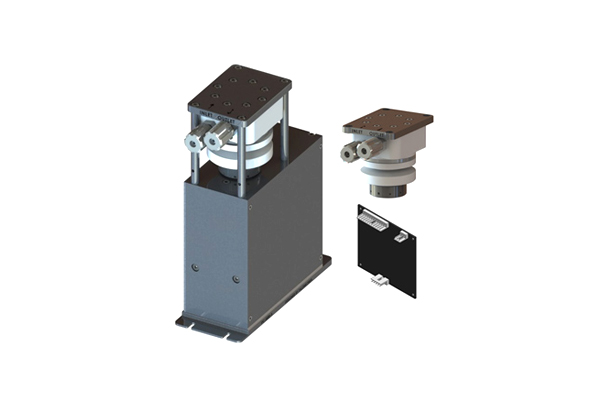

- DC Servo Motor Pumps, including models TP-34A and TP-34R, represent a core technology for precise dispense volume control and high repeatability. The TP-50BS model, based on a DC servo motor, features a touchpad controller capable of managing up to 16 pumps, automatic bubble venting and PR charging, a compact design, diaphragm and bubble trap technologies, and an Easy Purge Function for optimized buffer tanks, special welding, and no leak points.DC Servo Motor Pumps, including models TP-34A and TP-34R, represent a core technology for precise dispense volume control and high repeatability. The TP-50BS model, based on a DC servo motor, features a touchpad controller capable of managing up to 16 pumps, automatic bubble venting and PR charging, a compact design, diaphragm and bubble trap technologies, and an Easy Purge Function for optimized buffer tanks, special welding, and no leak points.

- Stable 5 Phase Step Motor Control Pumps, such as models TP-22R and TP-30BS, utilize stable step motor control technology for consistent dispense volume. They offer reliable performance across various liquid viscosities, building a highly dependable dispensing system.Stable 5 Phase Step Motor Control Pumps, such as models TP-22R and TP-30BS, utilize stable step motor control technology for consistent dispense volume. They offer reliable performance across various liquid viscosities, building a highly dependable dispensing system.

- Air Cylinder Pumps, models TP-10 and TP-12, are developed for compatibility with semiconductor and LED track systems. All PR-contacting points are made of Teflon for chemical stability, and they employ an inner-type bellows dispensing method. These pumps offer a dispense volume range of 0.7cc to 8.0cc and can handle viscosities up to 150cP.Air Cylinder Pumps, models TP-10 and TP-12, are developed for compatibility with semiconductor and LED track systems. All PR-contacting points are made of Teflon for chemical stability, and they employ an inner-type bellows dispensing method. These pumps offer a dispense volume range of 0.7cc to 8.0cc and can handle viscosities up to 150cP.

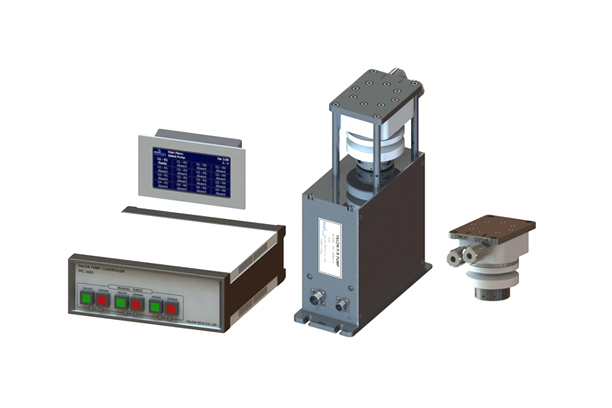

- Excellent Dispense Volume Reliability Pumps, including models TP-32BA and TP-40BA, feature an automatic bubble removal system, automatic degassing function, recirculation and purge stages for bubble elimination, and automatic PR return to the buffer tank to remove pressure in the filter. They ensure precise dispensing reliability through an outer-type bellows mechanism.Excellent Dispense Volume Reliability Pumps, including models TP-32BA and TP-40BA, feature an automatic bubble removal system, automatic degassing function, recirculation and purge stages for bubble elimination, and automatic PR return to the buffer tank to remove pressure in the filter. They ensure precise dispensing reliability through an outer-type bellows mechanism.

- Core Advantages

- Precision dispensing technology utilizing DC servo motors enables fine control of liquid volumes and high repeatability, a key competitive edge. This capability meets the stringent standards required in high-precision industries like semiconductor manufacturing.Precision dispensing technology utilizing DC servo motors enables fine control of liquid volumes and high repeatability, a key competitive edge. This capability meets the stringent standards required in high-precision industries like semiconductor manufacturing.

- The ability to control up to 16 pumps simultaneously via a single touchpad enhances user convenience and system efficiency. This allows for integrated management of multiple pumps through a unified interface in complex processes.The ability to control up to 16 pumps simultaneously via a single touchpad enhances user convenience and system efficiency. This allows for integrated management of multiple pumps through a unified interface in complex processes.

- Maintenance time-saving features, such as the Easy Purge Function and optimized buffer tank, are differentiating factors that contribute to increased productivity. These features minimize equipment downtime, improving operational efficiency.Maintenance time-saving features, such as the Easy Purge Function and optimized buffer tank, are differentiating factors that contribute to increased productivity. These features minimize equipment downtime, improving operational efficiency.

- Providing stable performance across a wide range of liquid viscosities ensures flexibility for application in diverse industrial sectors. The company maintains consistent precision dispensing capabilities for both high and low-viscosity liquids.Providing stable performance across a wide range of liquid viscosities ensures flexibility for application in diverse industrial sectors. The company maintains consistent precision dispensing capabilities for both high and low-viscosity liquids.

- Expertise in both PR pumps and PR sensors strengthens the company's ability to offer total solutions. Integrated pump and sensor technologies enable more precise and stable process control.Expertise in both PR pumps and PR sensors strengthens the company's ability to offer total solutions. Integrated pump and sensor technologies enable more precise and stable process control.

- The capability to develop customized products based on customer requests demonstrates a flexible business structure that quickly responds to market changes and fulfills specific client requirements.The capability to develop customized products based on customer requests demonstrates a flexible business structure that quickly responds to market changes and fulfills specific client requirements.

- Target Industrie

- Precision PR (Photoresist) dispensing processes in the semiconductor manufacturing industry.Precision PR (Photoresist) dispensing processes in the semiconductor manufacturing industry.

- Precision liquid dispensing systems in display panel manufacturing processes.Precision liquid dispensing systems in display panel manufacturing processes.

- Various advanced industrial fields requiring precise dispensing of high-viscosity liquids.Various advanced industrial fields requiring precise dispensing of high-viscosity liquids.

- Liquid material supply systems in LED production processes.Liquid material supply systems in LED production processes.

- Major Markets

- Certifications/Patents

- While no official patent or certification records are explicitly confirmed, the precision dispensing technology utilizing DC servo motors is a significant technical strength of the company.While no official patent or certification records are explicitly confirmed, the precision dispensing technology utilizing DC servo motors is a significant technical strength of the company.

- The accumulated years of know-how in PR pump and PR sensor fields since its establishment in 2005 represent a strong technical foundation.The accumulated years of know-how in PR pump and PR sensor fields since its establishment in 2005 represent a strong technical foundation.

- Proprietary technological development capabilities include automatic bubble removal systems, automatic degassing functions, and recirculation and purge stages.Proprietary technological development capabilities include automatic bubble removal systems, automatic degassing functions, and recirculation and purge stages.

Introduction

Key Products

Location

33-30 Jeongnamdong-ro, Jeongnam-myeon, Hwaseong-si, Gyeonggi-do, South Korea

클릭하여 위치 살펴보기