STANDARD INDUSTRIE INTERNATIONAL

LIFTUBE® Conveyor Belt Skirting

Model

Series

CONVEYOR BELT OPTIMISATION

Transaction Process

Please contact the manufacturer/supplier.

Payment

Contact the manufacturer/supplier.

Delivery

Contact the manufacturer/supplier.

Shipment

Contact the manufacturer/supplier.

Origin

Contact the manufacturer/supplier.

Description

LIFTUBE®, CONVEYOR BELT SKIRTING

OUR ACCESSORIES FOR CONVEYOR BELT : YOUR ANSWER FOR PROBLEMS OF SEALING AND SAFETY

The patented LIFTUBE® and the dust-collector are accessories for conveyor belt.

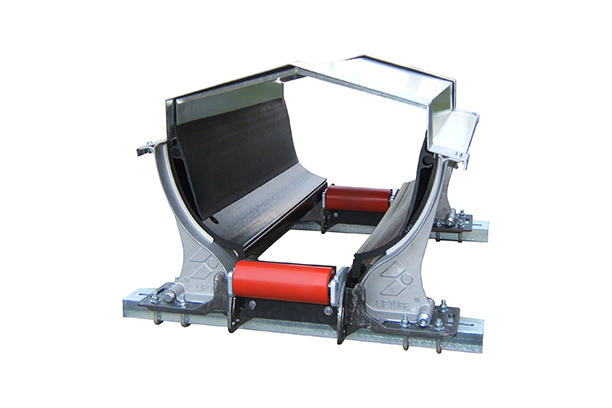

The LIFTUBE® system enables the belt to run on a central horizontal tilting roller and to slide on the edges, which also tilt.

A removable hood can be adapted to the equipment to reduce belt conveyor dust emission. Only the size of the hood and the central horizontal roller depends on the width of the conveyor. The conveyor belt and rollers can be easily accessed thanks to innovative tilting glideboards.

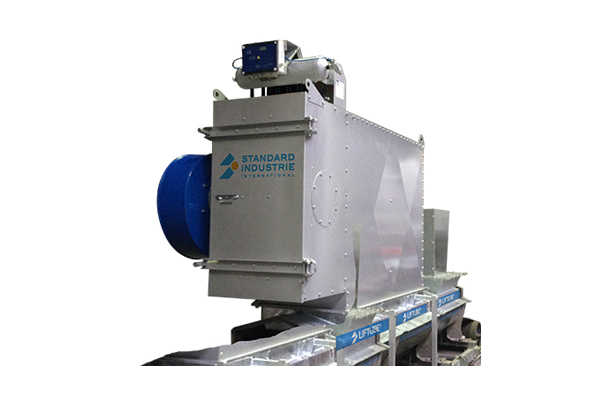

The dust-collector is a 2m-LIFTUBE® kit with filtering unit atop of hood – air-jet filter cleaning. Allow reduction of very fine dust emission just after discharge.

- Belt width : from 500 to 1400 mm

- Belt speed : 0.05 to 5 m/s

- Output : Up to 1500 tons/h

- Particle size : up to 500 mm

- Density : up to 4

- Product temperature : up to300°C (570 °F)

- Standard & evolutive modules

- Suitable for both new or existing conveyors

ENVIRONMENT : Dust emissions reduction between the loading and off-loading points: compliance with current standards (ISO 14001)

QUALITY : Contamination free for your product/Longer service life of the belt

TOTAL SAFETY : Protection of pinch points in accordance with official norms

SAVINGS : No change in the existing structure/optimization of output/no loss of production

MAINTENANCE : Easy & quick access to the belt during maintenance operations

MODULAR : Standard, adaptable and evolutive elements on new or existing conveyors/Installation on all or part of the conveyor/Compatible with reversible belt

- Visits & technical recommendations (proportioning and layout)

- Supply of the installation plan

- We offer complete installation of our equipment if needed

- Up to 3-year warranty

- On-site & external training (STANDARD INDUSTRIE training institute: IFSI – No. 31 59 05660 59)

- After-sales service & maintenance contract

- Statutory monitoring

- ATEX/Food industry/Auto-extinguishing

- High temperature (product temperature up to 300°C /570°C)

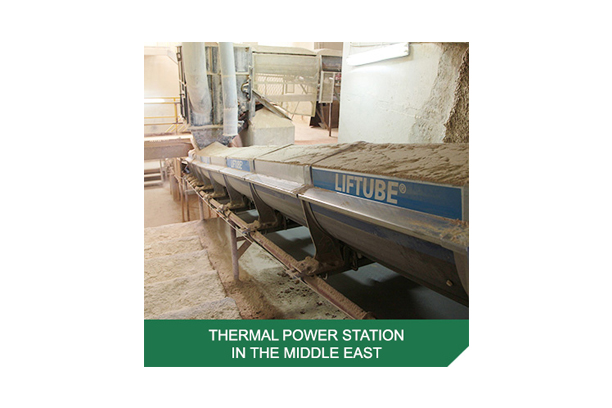

CUSTOMER : Thermal power station in the Middle East

PROBLEM : The customer encountered various problems on one of the main conveyors taking coal from the hoppers to the boiler rooms:

⋅ Overflowing of material => employees required to carry out regular cleaning & substantial maintenance of station rollers

⋅ Polluting & explosive atmosphere

PRODUCT : Coal

OBJECTIVE : Reduce loss of products & cleaning/maintenance time and purify the atmosphere.

SOLUTION : 15 m of wide (1000 mm) LIFTUBE from a raise equipped with a 2 m hopper hood.

RESULT : The sealing of the conveyor was optimised and enabled the customer to reduce dust emissions, loss of material and therefore the cleaning/maintenance time by 95%.

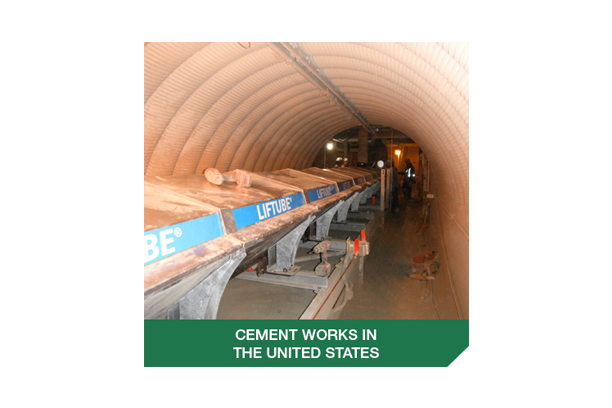

CUSTOMER : Cement plant in the USA

PROBLEM : Loss of product overflowing on the conveyor. Flying dust.

PRODUCT : Cement

OBJECTIVE : To eliminate the loss of product and control dust emission.

SOLUTION : 15 m of LIFTUBE Large Width (the first in the USA)

RESULT : Customer 100% satisfied with the solution, which was duplicated on sister sites.