This product is manufactured by

SONY ELECTRONICS OF KOREA CORPORATION

Manufacturer information

SONY ELECTRONICS OF KOREA CORPORATION

Verified & Trusted Manufacturer

High precision parts manufacturer, Laser Diode, Pick Projector, Integrated Unit

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

SONY ELECTRONICS OF KOREA CORPORATION

Product Type

Machine

Brand

-

SKU

124645

Product Name

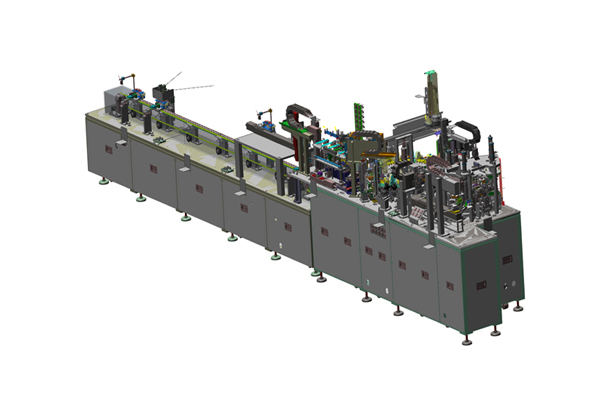

ez-VISION

Model Name

-

Size

-

Weight

-

Product Details

More products

Assembly Equipment

Automatic Packing Machine of Finished Products

Robot utilized Image Processing Inspection

Index type parts assembly Equipment

Non-woven fabric Attach Equipment

Auto-assembly Line of Cooling Fin

Electrolytic liquid Injection Equipment

Aluminum Thin Film Forming Equipment

Electronics Pre-Adjustment & Inspection Line

Automatic Loader of Finished Products

Stand-alone type parts assembler

USB Charger Auto-Assembly Equipment for Automotive

Weather Strip Clip Insertion Machine

Deformed Parts Stick Feeder for High-Speed Mounting

Deformed Parts Bowl Feeder for High-Speed Mounting feeder

1/4