This product is manufactured by

SHINSUNG YOUL YEON

Manufacturer information

SHINSUNG YOUL YEON

Industrial furnace manufacturer, Electric furnace, Heat processing furnace, Test furnace, Continuous furnace, Hot stamping furnace and more

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

SHINSUNG YOUL YEON

Product Type

Machine

Brand

-

SKU

142122

Product Name

Elevator Furnace

Model Name

-

Size

-

Weight

-

Product Details

More products

Refractory BrickSK-34, SK-36, SK-38

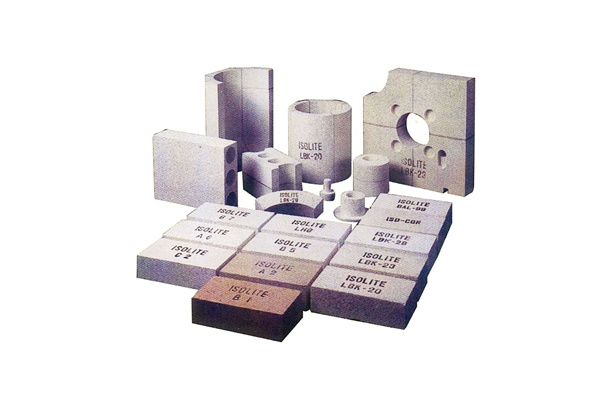

Insulation BrickB1, B2, B3, B4, B5, B6, B7, C1, C2, C3, LBK28, LBK30, LBK3000, BAL99, BAL99M

SILICA BOARD / HTB BOARDBD-200, BD-230, BD-250, BD-270

Castable / Mortar

Laboratory Chamber Furnace ( up to 1300℃)

Industrial Chamber Furnace ( up to 1800ºC)

Thermocouple

Hardener

Coating Cement

Fiber Cast

Ceramic Bond

SIC Plate

SISIC Material

Ceramic Tape / Rope

Ceramic Bulk

Ceramic Paper

1/4