This product is manufactured by

ROBOWEL

Manufacturer information

ROBOWEL

Specialized in welding automation, arc welding and resistant welding for LNG tank

Inquiry

How to order

Problem with product info?

Update request

Manufacturer

ROBOWEL

Product Type

Machine

Brand

-

SKU

115951

Product Name

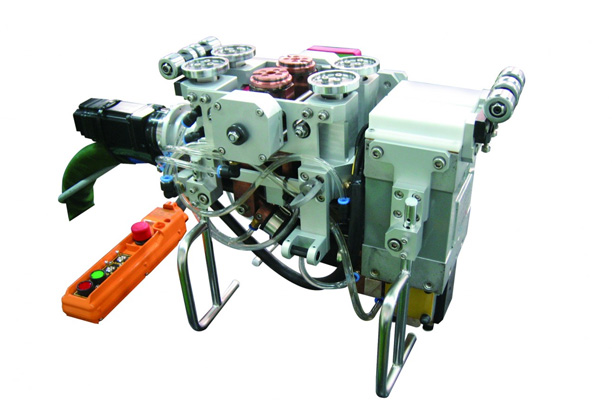

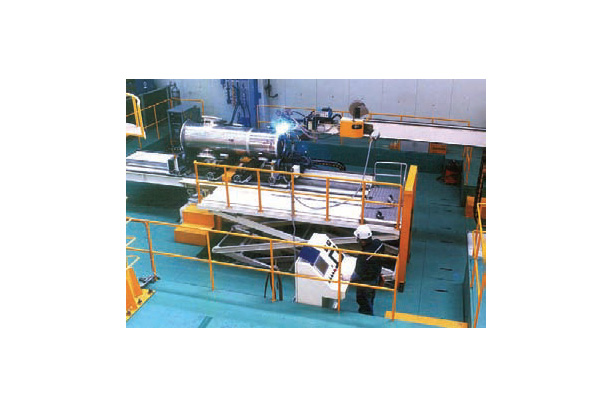

INVERTER SEAM W/D M/C FOR STRAKE/TONGUE

Model Name

-

Size

-

Weight

-

Product Details

More products

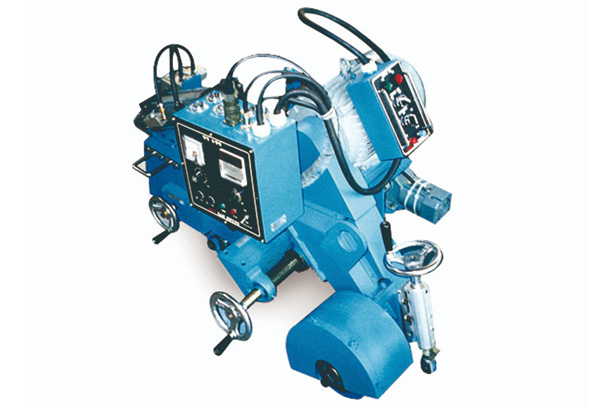

MINI ELECTRO GAS AUTO WELDING MACHINESH-EGW-1, SH-EGW-TANDEM

1-TORCH MINI WELDING CARRIAGESH-720-M5

HORIZONTAL ELECTRO GAS AUTO WELDING MACHINEH-EGW-1

VERTICAL FILLET WELDING MACHINESH-721-DW

MINI RAIL AUTO WELDING MACHINESH-820-VB

Automatic Full Welding CarriageSH-720-ROBOZERO

PORTABLE MILLING MACHINE

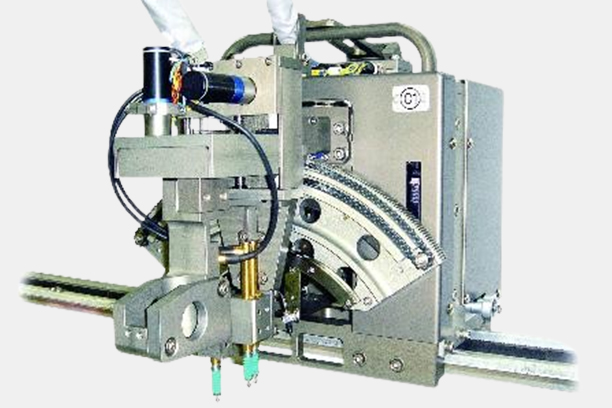

NARROW GROOVE WELDING MACHINE

Pipe Inside/Outside Welding Machine

24-Pole Longi Welding Machine

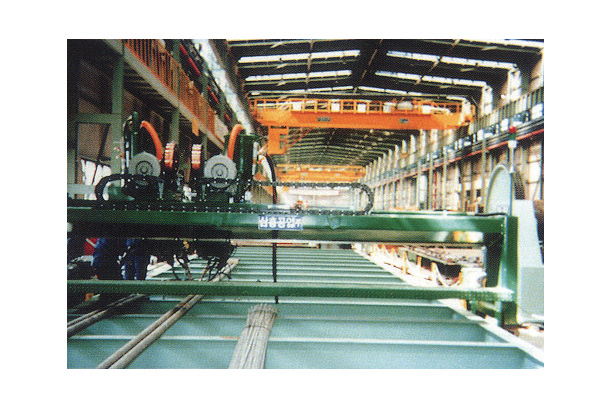

SAW Panel Welding Machine

SAW-FCAW Welding Test Machine

Roller Overlay Welding Machine

Automatic Boiler-Panel Welding Machine

Automatic AL MIG Pipe Welding Machine

Automatic T-BAR Welding Line

1/4